Method and system for recovering waste water generated in carbocisteine production

A technology for carbocisteine and waste water production, applied in chemical instruments and methods, natural water treatment, multi-stage water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

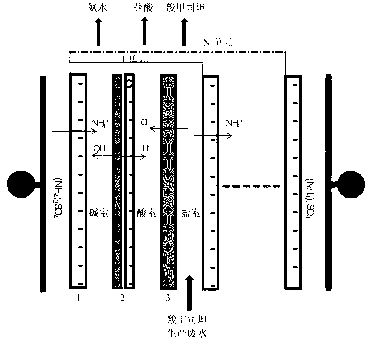

[0067] A three-compartment 6-unit BP-A-C / BMED bipolar membrane electrodialysis system composed of bipolar membranes, anion exchange membranes, and cation exchange membranes arranged alternately in sequence, see figure 1 , where the effective area of the membrane is 842cm 2 . The contents of ammonium chloride and carbocisteine in the carbocisteine production wastewater tested in this example were 2 mol / L and 1 g / L respectively, and the conductivity was 171 mS / cm. Pump carbocisteine production wastewater into the salt chamber. The alkali chamber uses the ammonia solution with a concentration of 0.05mol / L as the initial solution. The acid chamber uses the hydrochloric acid solution with a concentration of 0.05mol / L as the initial solution. L of sodium chloride solution. Under the conditions of membrane surface flow rate of 3cm / s and external constant voltage of 16V, the intermittent operation mode is adopted, and the pH of the salt chamber is adjusted between 2 and 3 w...

Embodiment 2

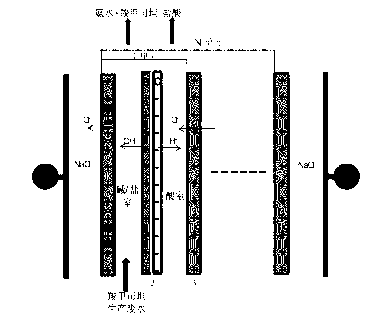

[0071] The BP-C / BMED bipolar membrane electrodialysis system with bipolar membranes and cation exchange membranes alternately arranged to form two compartments and five units, see figure 2 , where the membrane effective area is 735cm 2 , The thickness of the partition is 0.132cm. The contents of ammonium chloride and carbocisteine in the carbocisteine production wastewater tested in this example were 0.5 mol / L and 1 g / L respectively. Carbocisteine production wastewater is pumped into the acid / salt chamber, the alkali chamber uses ammonia solution with a concentration of 0.05 mol / L as the initial solution, and the electrode chamber uses 0.5 mol / L sodium chloride solution. The flow velocity on the membrane surface is 3cm / s and the current density is 500A / m 2 Under certain conditions, the intermittent operation mode is adopted, and the pH value and conductivity in the alkali chamber and the acid / salt chamber are monitored online. The electrodialysis separation was termi...

Embodiment 3

[0074] The bipolar membrane electrodialysis system adopted in this embodiment is the same as that in Embodiment 2. The content of ammonium chloride and carbocisteine in the carbocisteine production wastewater tested in this example was 2mol / L and 1g / L respectively. Carbocisteine production wastewater is pumped into the acid / salt chamber, the alkali chamber uses ammonia solution with a concentration of 0.05 mol / L as the initial solution, and the electrode chamber uses 0.5 mol / L sodium chloride solution. The flow velocity on the membrane surface is 3cm / s and the current density is 500A / m 2 Under certain conditions, the intermittent operation mode is adopted, and the pH value and conductivity in the alkali chamber and the acid / salt chamber are monitored online. The electrodialysis separation was terminated when the conversion rate of salt in the acid / salt chamber was 40%.

[0075]The concentration of ammonia water in the alkali chamber is 0.62mol / L, the concentration of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com