Preparation method of N,N'-bis(3-aminopropyl)-1,2-ethylenediamine

An aminopropyl, ethylenediamine technology, applied in the N field, can solve the problems of high energy consumption, low yield and high cost, and achieve the effects of reducing distillation and purification steps, reducing waste liquid discharge, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

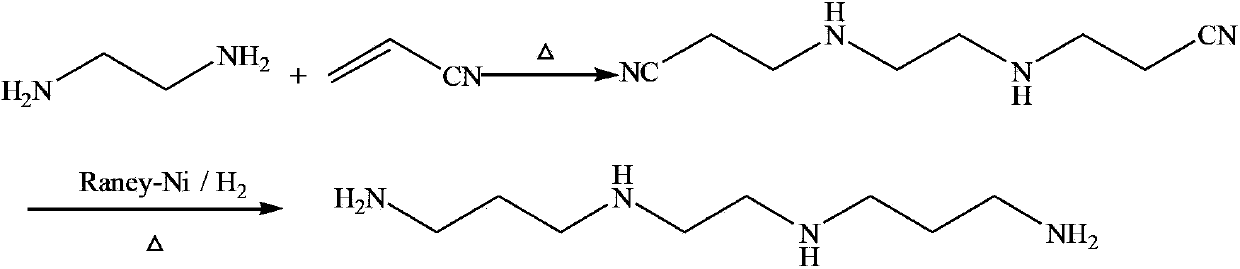

Method used

Image

Examples

Embodiment 1

[0049]In a 1000mL stirred reaction flask, add 120g (2mol) ethylenediamine and 300g ethanol, then add 213g (4.1mol) acrylonitrile dropwise within 2 hours, and keep the temperature below 60°C. After the dropwise addition, keep it warm for 2 hours. According to GC analysis, the content of N,N′-bis(cyanoethyl)-1,2-ethylenediamine is 97.6% (GC, peak time: 10.5min).

Embodiment 2

[0051] In a 1000mL stirred reaction flask, add 120g (2mol) ethylenediamine and 300g isopropanol, then add 233g (4.4mol) acrylonitrile dropwise within 3 hours, and keep the temperature below 50°C. After the dropwise addition, keep it warm for 2 hours. According to GC analysis, the content of N,N′-bis(cyanoethyl)-1,2-ethylenediamine is 89% (GC, peak time: 10.5min).

Embodiment 3

[0053] In a 1000mL stirred reaction flask, add 120g (2mol) ethylenediamine and 300g methanol, then add 217g (4.1mol) dropwise within 2h, and keep the temperature below 60°C. After the dropwise addition, keep it warm for 2 hours. According to GC analysis, the content of N,N′-bis(cyanoethyl)-1,2-ethylenediamine is 90% (GC, peak time: 10.5min).

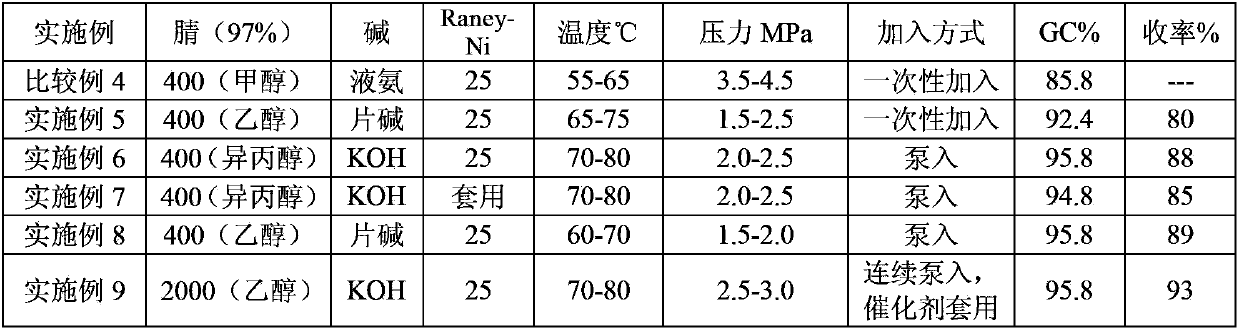

[0054] form one

[0055] the batch

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com