Method for separating and purifying straight-chain hemicellulose and branched-chain hemicellulose from biomass

A hemicellulose, separation and purification technology, applied in the field of hemicellulose separation and purification, can solve the problems of inability to cleanly dissociate biomass components, low efficiency of component conversion process, and few types of products, etc., and achieve high utilization rate , short time-consuming and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

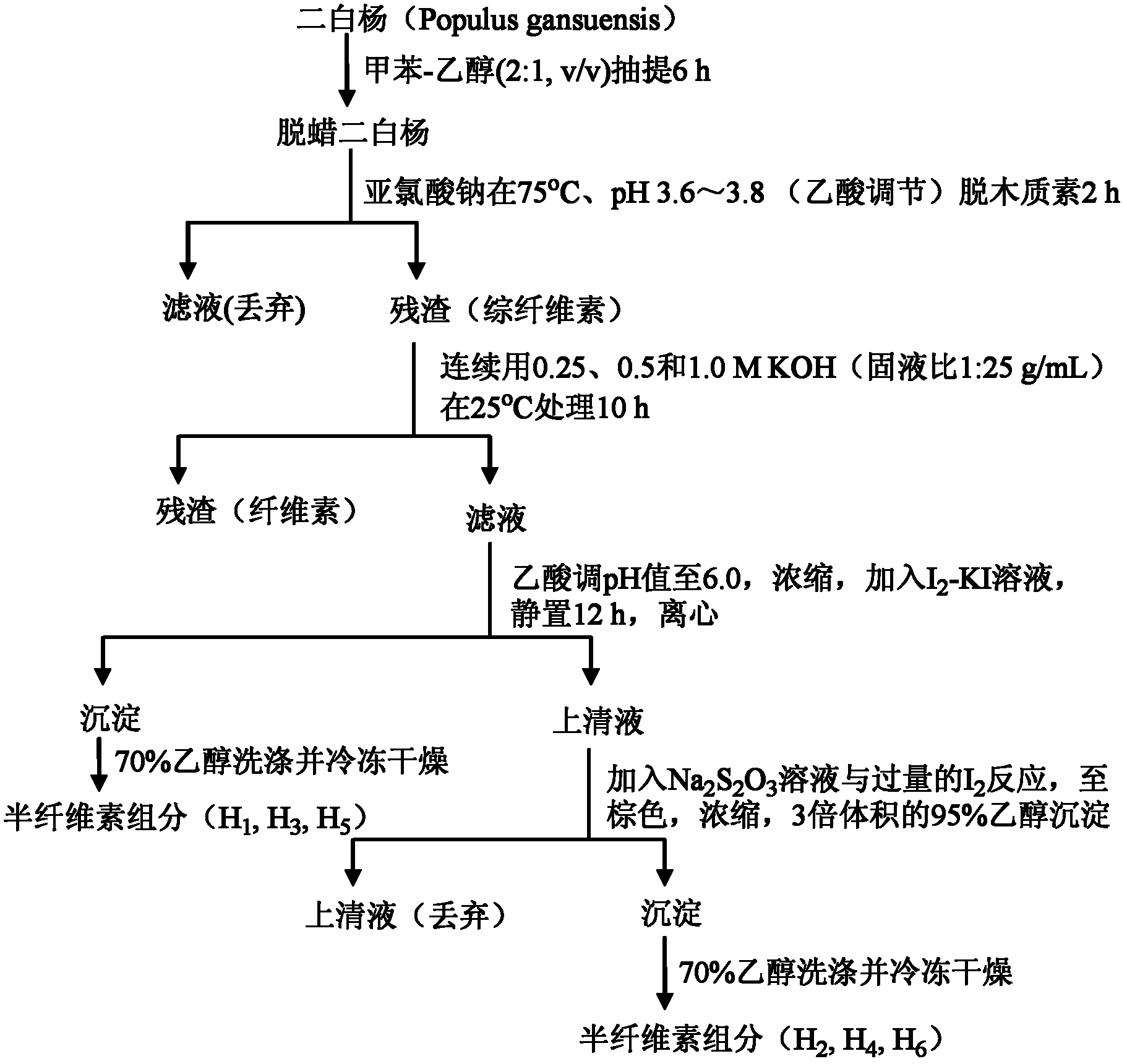

[0026] Taking poplar as an example to specifically illustrate the method for separating and purifying linear hemicellulose and branched hemicellulose from biomass in the present invention, such as figure 1 As shown, in this embodiment, the method includes:

[0027] Step 1. Peel the two poplar trunks, dry them and cut them into small pieces of 1 to 3 cm, grind them, pass through a sieve with an aperture of 1.0 to 3.0 mm to obtain two poplar powder, and then use 50 g of the dried poplar powder with a volume ratio of 2:1 toluene and ethanol were placed in a Soxhlet extractor for 6 hours to obtain dewaxed poplar, and then the dewaxed poplar was dried in an oven at 60°C for 16 hours.

[0028] Step two, treat the dewaxed poplar with sodium chlorite at 75℃ for 2h, and adjust the pH value between 3.6~3.8 with acetic acid. The residue obtained after treatment is washed with distilled water and ethanol, and then at 60℃ Bake for 16h to obtain holocellulose.

[0029] Step 3: The holocellulose w...

Embodiment 2

[0041] In Example 2, Caragana korshinskii was taken as an example to illustrate the method for separating and purifying linear hemicellulose and branched hemicellulose from biomass according to the present invention, and the method includes:

[0042] Step 1: Peel the trunk of Caragana korshinskii tree and dry it and cut it into small pieces of 1~3cm, grind it, pass through a sieve with an aperture of 1.0~3.0mm to obtain Caragana korshinskii powder, and then 50g dried Caragana korshinskii The powder was extracted with a volume ratio of 4:1 toluene and ethanol in a Soxhlet extractor to extract 50 g of ground two white poplar for 8 hours to obtain dewaxed Caragana korshinskii and dried in an oven at 60°C for 18 hours.

[0043] Step two, treat the dewaxed Caragana korshinskii with sodium chlorite at 85℃ for 3h, and adjust the pH value between 3.6~3.8 with acetic acid. The residue obtained after treatment is washed with distilled water and ethanol, and then at 40 Bake at ℃ for 18h to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com