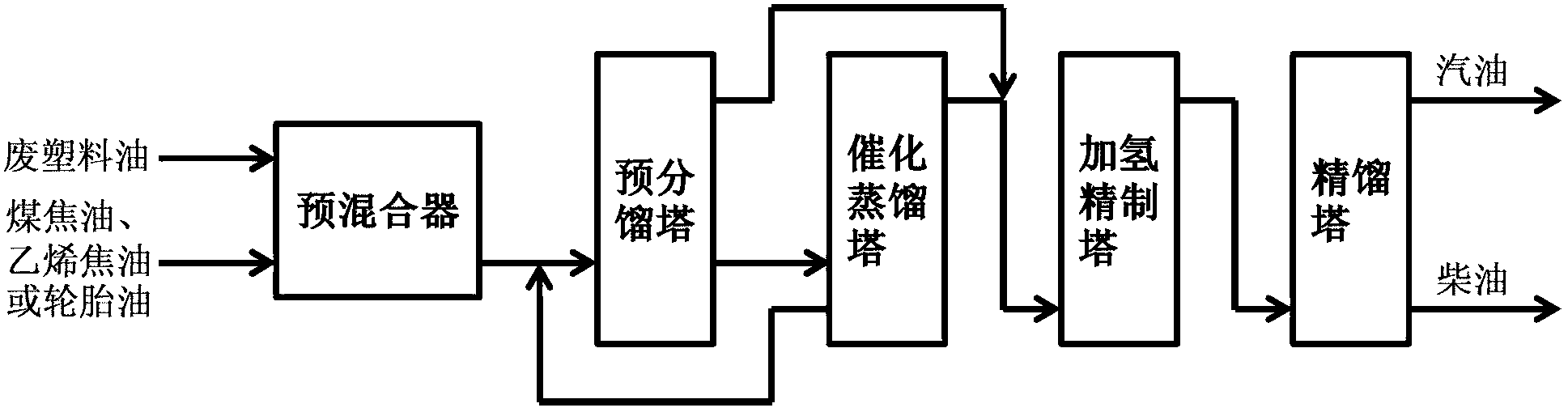

Method for producing gasoline and diesel oil by mixing and refining plastic oil, coal tar, ethylene tar or tire oil

A kind of ethylene tar and mixed refining technology, which is applied in the petroleum industry, processing hydrocarbon oil, refining to remove heteroatoms, etc., can solve the problems of unable to adjust gasoline octane number on demand, unfavorable continuous operation, high coking content, etc., to achieve extended Hydrofining catalyst life, reduction of coking amount, effect of reducing coking amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Plastic oil and coal tar are mixed and injected into the pre-fractionation tower at a volume ratio of 1:0.1, and the pre-fractionation tower is at 300 o C is fractionated into light components and heavy components, and the light components are directly passed through Al 2 o 3 Supported NiMo sulfide catalyst hydrorefining reaction, control the feed temperature at 320 o C. Hydrogen partial pressure 6 MPa, volumetric space velocity 0.5 h -1 , The volume ratio of hydrogen to oil is 600:1; the hydrogen is recycled after being separated and purified. The heavy component is rectified by the catalytic distillation tower filled with alumina and Y-type zeolite composite catalyst. The distillate oil after reactive rectification can directly enter the hydrogenation reactor for hydrofining, and part of it will be injected into the pre-fractionator for re-reaction and hydrofining. The final distillate is cut into gasoline (180°C) according to the distillation temperatur...

Embodiment 2

[0018] Embodiment 2: Plastic oil and ethylene tar are mixed and injected into the pre-fractionation tower at a volume ratio of 1:0.5, and the pre-fractionation tower is at 300 o C is fractionated into light components and heavy components, and the light components are directly passed through SiO 2 -Al 2 o 3 Supported NiMoW sulfide catalyst hydrorefining reaction, the feed temperature is controlled at 260 o C. Hydrogen partial pressure 4 MPa, volumetric space velocity 1 h -1 , The volume ratio of hydrogen to oil is 400:1; hydrogen is recycled after separation and purification. The heavy component is rectified by the catalytic distillation tower filled with alumina and β molecular sieve composite catalyst. The distillate oil after reactive rectification can directly enter the hydrogenation reactor for hydrofining, and part of it will be injected into the pre-fractionator for re-reaction. After hydrofining The distillate is cut into gasoline (180°C) according to the distillat...

Embodiment 3

[0019] Embodiment 3: Plastic oil and tire oil are mixed and injected into the pre-fractionation tower at a volume ratio of 1:1, and the pre-fractionation tower is at 300 o C is fractionated into light components and heavy components, and the light components are directly passed through Al 2 o 3 Supported CoMo sulfide catalyst hydrorefining reaction, the feed temperature is controlled at 300 o C. Hydrogen partial pressure 4 MPa, volumetric space velocity 1 h -1 , The volume ratio of hydrogen to oil is 800:1; hydrogen is recycled after separation and purification. The heavy components are rectified through the catalytic distillation column filled with alumina catalyst containing 30% ZSM-5 and 10% β zeolite. The distillate oil after reactive rectification can directly enter the hydrogenation reactor for hydrofining, and part of it will be injected into the pre- The fractionation tower reacts again, and the distillate oil after hydrofining is cut into gasoline (180°C) according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com