High-strength high-modulus magnesium alloy and preparation method

A high-strength, high-modulus, magnesium alloy technology, applied in the field of non-ferrous metal materials and its processing, can solve the problems of low elastic modulus, poor elastic deformation resistance and low elastic modulus of Mg-RE alloys, and achieve high room temperature strength and Elastic modulus, good plasticity, easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

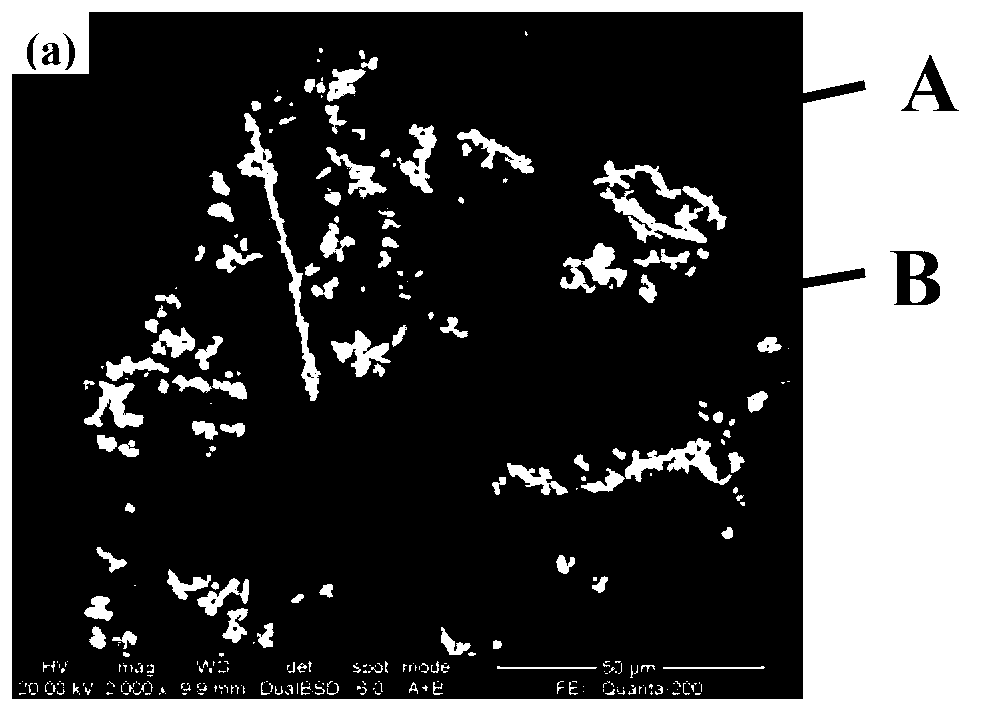

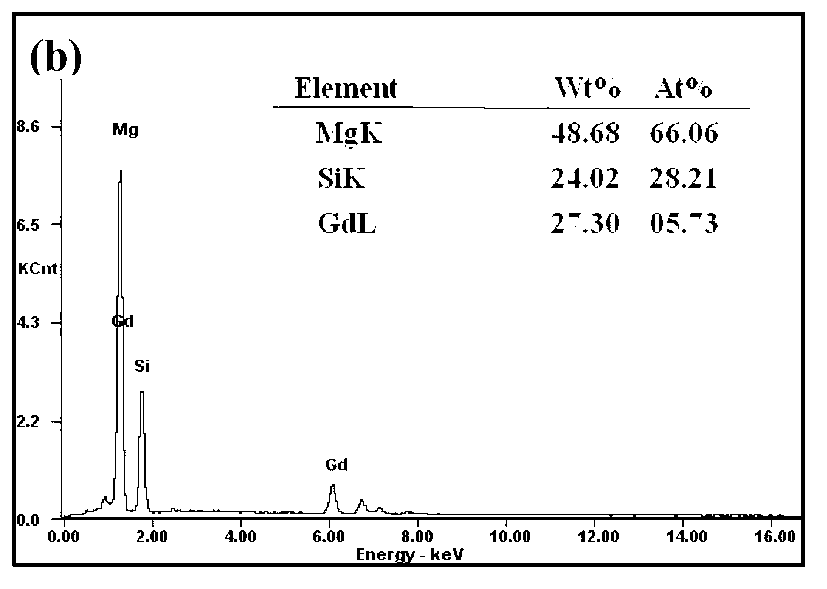

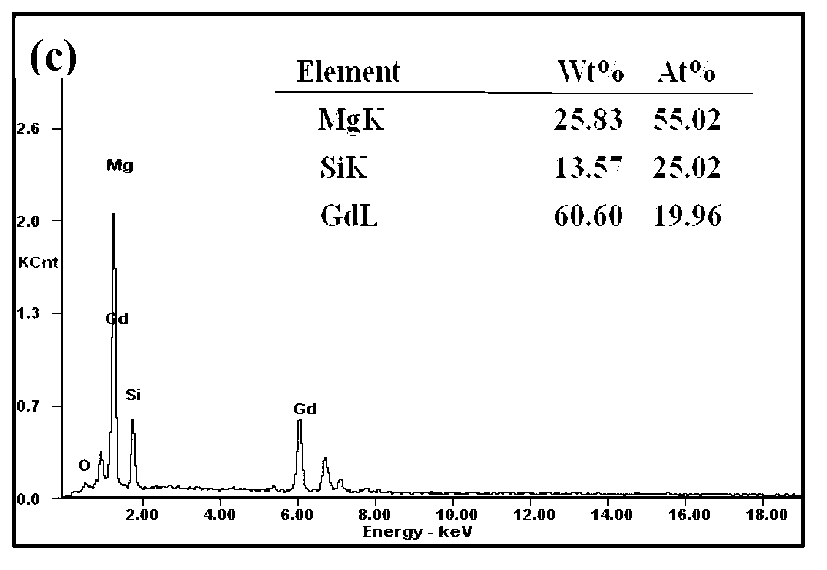

Image

Examples

Embodiment Construction

[0042] In the embodiment of the present invention, the preparation method of the alloy is the same, that is, each component is selected according to the designed high-strength and high-modulus magnesium alloy component distribution ratio, wherein: Mg is added in the form of pure magnesium, and Si and Zn are added in the form of pure silicon and pure zinc. Add the other components in the form of magnesium-based master alloy; put the pure magnesium ingot into the iron crucible and heat it to 750°C under the protective atmosphere of Ar gas. After the pure magnesium ingot is melted, add the pure silicon into the In the pure magnesium melt, the pure silicon has a particle size of 1.0~2.0cm. Stir the melt once every 5 minutes at a speed of 300rpm. The divided master alloy is stirred, refined and slag removed, and cast to obtain ingots; all master alloys are completely melted and refined and slag removed until the casting time is less than or equal to 4 minutes.

[0043] The prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com