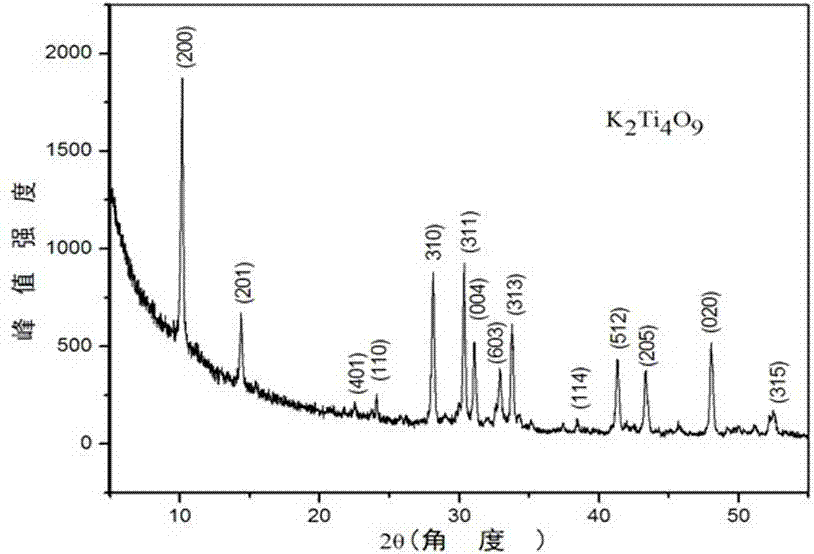

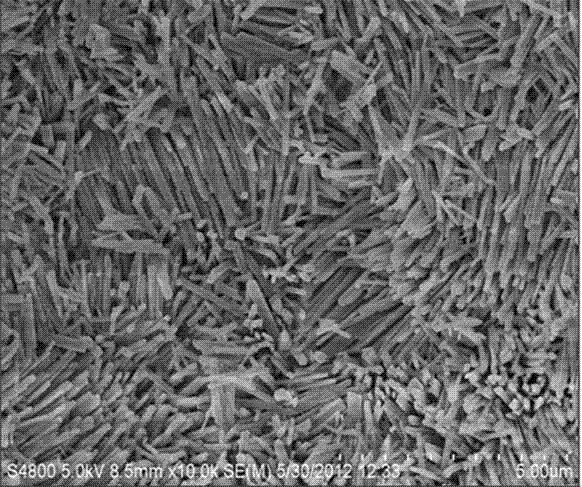

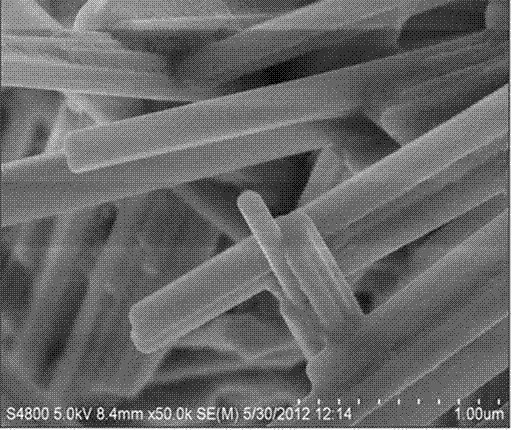

Method for preparing ultrathin layered K2Ti4O9 crystal whiskers

A layered and whisker technology is applied in the field of stearic acid preparation of ultra-fine layered K2Ti4O9 whiskers to achieve the effects of high efficiency, reduced agglomeration and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Heat and melt 30g of stearic acid at 80°C, after it is completely melted, press Ti(OC 2 h 5 ) 4 / KNO 3 Add the initial material at a molar ratio of 2:2, that is, add 2mol / L KNO while hot while stirring 3 10ml of aqueous solution, the dropping rate is 45 drops / min; at the same time, add 6.8g of ethyl titanate to the above system, continue to stir for 50min after dropping, and get KNO 3 -Ti(OC 2 h 5 ) 4 Gel; burn off most of the organic matter in the above gel in an electric furnace at 550°C to obtain K 2 Ti 4 o 9 Precursor; after cooling, ball mill for 30 minutes, then heat up to 850°C at a heating rate of 7°C / min and calcined for 3 hours, and the layered K 2 Ti 4 o 9 whiskers.

Embodiment 2

[0033] Heat and melt 35g of stearic acid at 80°C, after it is completely melted, press Ti(OC 2 h 5 ) 4 / KNO 3 Add the initial material at a molar ratio of 2:2, that is, add 2mol / L KNO while hot while stirring 3 10ml of aqueous solution, the dropping rate is 40 drops / min; at the same time, add 6.8g of ethyl titanate to the above system, continue to stir for 40min after dropping, and get KNO 3 -Ti(OC 2 h 5 ) 4 Gel; burn most of the organic matter in the above gel in an electric furnace at 600°C to obtain K 2 Ti 4 o 9 Precursor; after cooling, ball mill for 30 minutes, then heat up to 800°C at a heating rate of 5°C / min and calcined for 5 hours, and the layered K 2 Ti 4 o 9 whiskers.

Embodiment 3

[0035] Heat and melt 35g of stearic acid at 90°C, after it is completely melted, press Ti(OC 2 h 5 ) 4 / KNO 3 Add the initial material at a molar ratio of 2:2, that is, drop in 2mol / L of KNO while hot while stirring 3 Aqueous solution 10ml, the rate of addition is 35 drops / min; at the same time, add 6.8g of ethyl titanate to the above system, continue to stir for 30min after dropping, and get KNO 3 -Ti(OC 2 h 5 ) 4 Gel; burn most of the organic matter in the above gel in an electric furnace at 600°C to obtain K 2 Ti 4 o 9 Precursor. After cooling, ball mill for 30 minutes, then heat up to 950°C for 2 hours at a heating rate of 5°C / min, and then calcine for 2 hours. After cooling in the furnace, the layered K 2 Ti 4 o 9 whiskers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com