Modified asphalt concrete with road surface cooling function

A technology of modifying asphalt and concrete, which is applied in the field of road materials, can solve the problems of affecting road surface performance, non-recyclable reuse, poor durability, etc., and achieve rich tourmaline mineral resources, reduce driving load damage, and high mechanochemical The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The modified asphalt concrete with road surface cooling function of this embodiment is made of the following raw materials: 100kg of ore material (aggregate containing mineral powder), 4.8kg of asphalt, 0.96kg of tourmaline, 0.24kg of expanded perlite, and 0.02 kg of additives. kg; the tourmaline is negative ion powder with anion release of 5000ions; the asphalt is SBS modified asphalt; the auxiliary agent is silane coupling agent KH550; The best oil-stone ratio is 4.8%.

[0019] The preparation method of the modified asphalt concrete in this example is as follows: add asphalt heated to 150°C to 170°C to aggregate (aggregate in mineral aggregate) at 180°C to 200°C and mix for 90 seconds, and then add electrical Stone, expanded perlite, additives and mineral powder (mineral powder in the mineral material), mixed again for 90-100 seconds, and then through the molding process, asphalt concrete with road surface cooling function can be obtained.

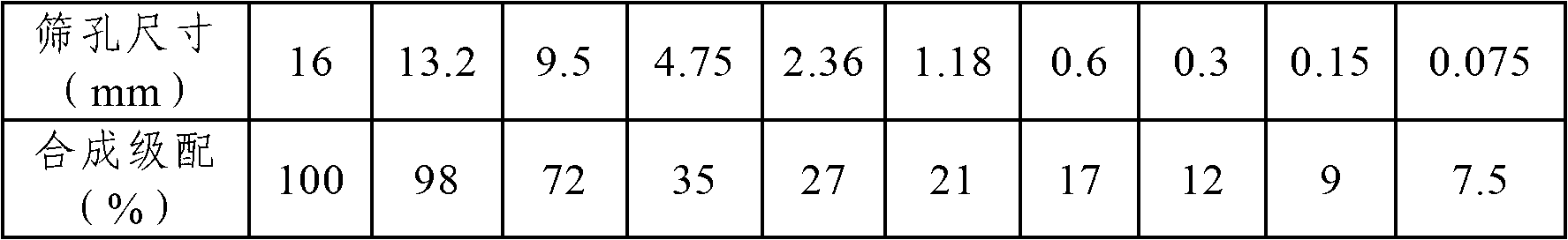

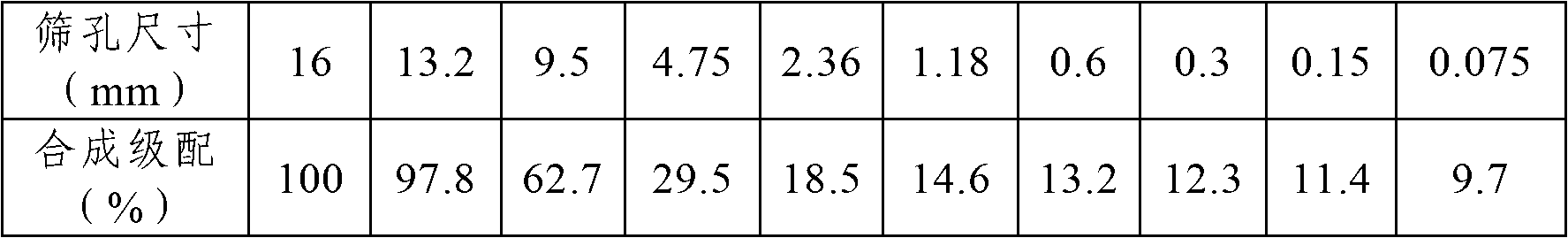

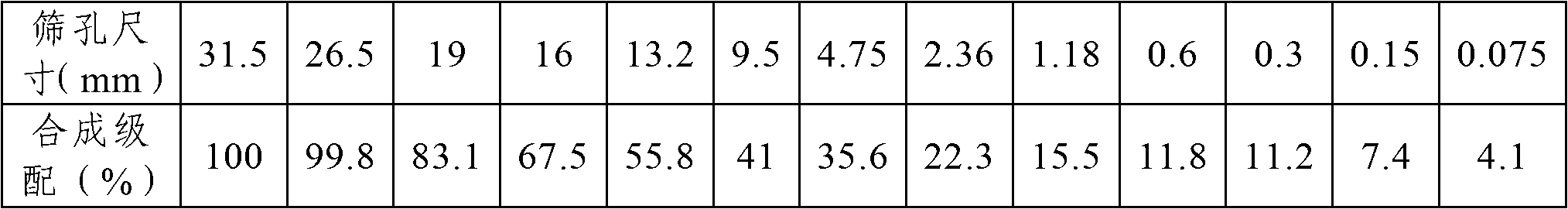

[0020] Table 1 Synthetic ...

Embodiment 2

[0023] The present embodiment is the same as Example 1, wherein the difference is that the asphalt is road petroleum asphalt, coal tar pitch, SBR modified asphalt or rubber modified asphalt; the tourmaline is tourmaline powder or tourmaline powder and tourmaline negative ion powder; the auxiliary agent is a titanate coupling agent.

Embodiment 3

[0025] The modified asphalt concrete with road surface cooling function of the present embodiment is made of the following raw materials: mineral aggregate 100kg, asphalt 4.8kg, tourmaline 0.8kg, expanded perlite 0.1kg, auxiliary agent 0.01kg; described tourmaline is negative ion Negative ion powder with a release rate of 8000 ions; the asphalt is SBS modified asphalt; the auxiliary agent is silane coupling agent KH560; the synthetic gradation of mineral materials is shown in Table 1, and the optimum asphalt ratio is 4.8%.

[0026] The preparation method of the modified asphalt concrete of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com