Method and apparatus used for preparing olive leaf extract

A technology of olive leaf extract and olive leaf, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve problems such as low efficiency, shortened production cycle, and long extraction time, so as to improve economic benefits, Shorten the production cycle and achieve good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

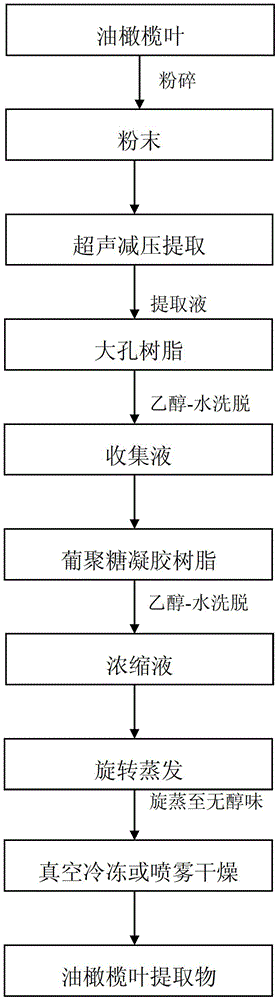

[0035] A preparation method of olive leaf extract:

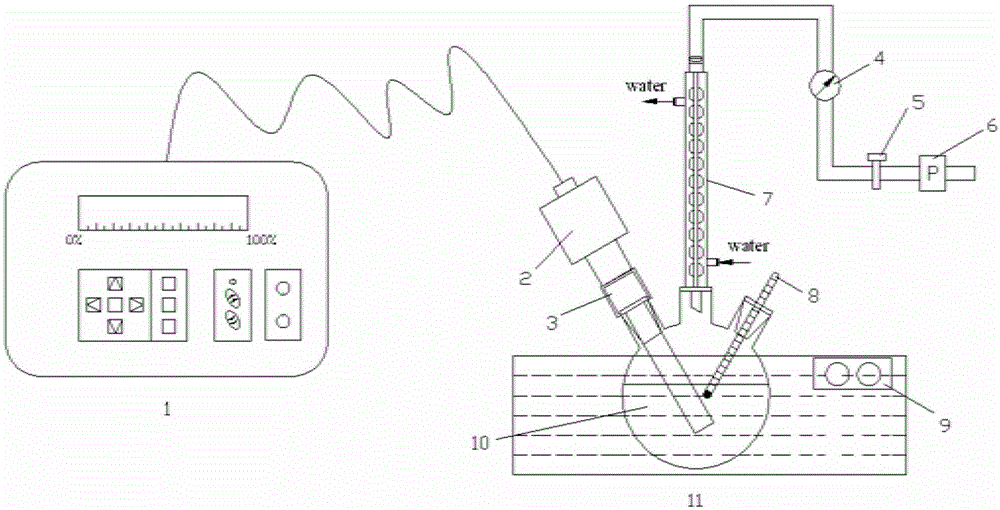

[0036] (1) Extraction: Weigh a certain amount of olive leaf powder (extraction device such as figure 2 shown), then add an appropriate amount of zeolite, use a polar solvent in the olive leaf and solvent ratio of 1:10~1:30 (w / v), extract at 40~50°C, and extract for 1~30 min. Under the conditions of ultrasonic power of 240-1200 W and system vacuum of 30-90 kPa, ultrasonic decompression boiling extraction is carried out, and the polar solvent is a mixed solution of ethanol and deionized water.

[0037] (2) Extraction: vacuum filter the extract in (1) above, transfer the collected supernatant to a separatory funnel, add petroleum ether for extraction, let stand for 10 minutes, and collect the lower supernatant.

[0038] (3) Column separation: Rotate the collected solution in (2) at 30~50°C to recover the solvent to obtain a certain amount of concentrated solution, then dilute it with an appropriate amount of deionized water, ...

Embodiment 1

[0045] (1) Extraction: 100 g of olive leaves that were naturally dried in the shade were crushed with a pulverizer, placed in an ultrasonic decompression extraction device, an appropriate amount of zeolite, 2 L of 75% ethanol were added, the temperature was 50 °C, the ultrasonic power was 600 W, and vacuum Ultrasonic-decompression boiling extraction was carried out under the conditions of 70 kPa and 5 min.

[0046] (2) Extraction: Add the collected extract into a separatory funnel with a capacity of 5 L, then add 500 ml of petroleum ether to extract three times, let stand for 10 min, and collect the lower layer of the layered liquid.

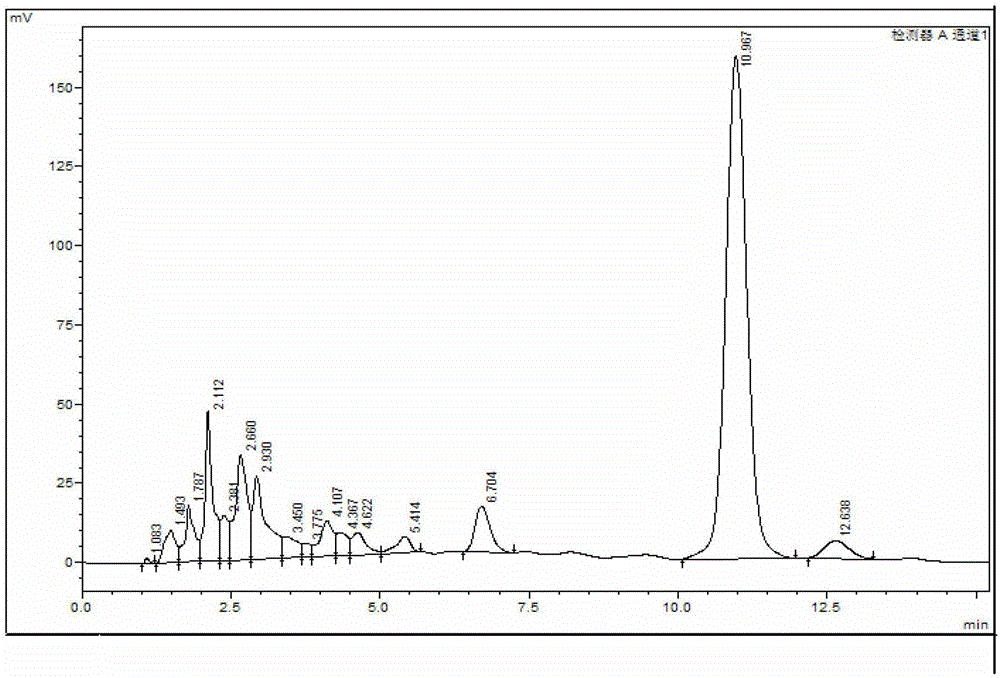

[0047] (3) Column separation: The lower layer liquid collected from the separatory funnel was rotary evaporated at 45°C to recover the alcohol solvent until the concentrated liquid had no alcohol smell, then diluted with 400ml of deionized water, separated by AB-8 macroporous resin, and adsorbed After 30 min, it was eluted with 70% ethanol, and ...

Embodiment 2

[0051] (1) Extraction: Weigh 300 g of naturally shade-dried olive leaves, pulverize them with a pulverizer, put them in an ultrasonic decompression extraction device, add an appropriate amount of zeolite, 3.5 L of 75% ethanol, the temperature is 45°C, and the ultrasonic power is 720 W. Ultrasonic-decompression boiling extraction was carried out under the conditions of vacuum degree of 75 kPa and time of 7 min.

[0052] (2) Extraction: Add the collected extract into a separatory funnel with a capacity of 5 L, then add 850 ml of petroleum ether to extract three times, let stand for 15 min, and collect the lower layer of the layered liquid.

[0053] (3) Column separation: The lower layer liquid collected from the separatory funnel was rotary evaporated at 50°C to recover the ethanol solvent and make the concentrated liquid have no alcohol smell, then added 750 ml of deionized water to dilute, and then separated by AB-8 macroporous resin , after 30 minutes of adsorption, elute wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com