Gas mixing controller of semiconductor device

A gas mixing and semiconductor technology, applied in various fluid ratio control directions, etc., can solve the problems that the safety and reliability of the system cannot be guaranteed, the establishment of the control system is not a norm, and it is not a normative supervision and control system, etc., and achieves strong module sealing and low cost. , powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

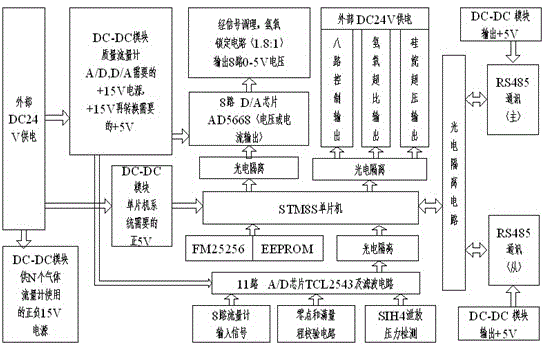

[0039] When used, such as Figure 7 Connect the controller to the electrical connector of the mass flow meter as shown. The controller fixes the mass flow meter interfaces and output positions of the three gases, hydrogen, oxygen and nitrogen, and cannot be changed. Other gas interfaces are customized through the host computer. The pointing signal of the controller is connected with the ground of the pressure signal of SIH4 and COM1. Hydroxygen overpressure and SIH4 overpressure signals are passive contacts, which are connected with external alarm or PLC and other control systems. The gas control output is connected to the corresponding electromagnetic control pneumatic valve.

[0040] Set the baud rate for communication with the host computer through the host computer, select the manufacturer of the mass flowmeter, set the hydrogen slow start time, set the hydrogen-oxygen ratio (1.8:1 to 2:1), set the gas sequence and limit value, set Gas storage interval.

[0041] The an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com