Mixed silicon single mode annular cavity laser based on microstructural silicon waveguide frequency selection

A microstructure, silicon waveguide technology, applied in the structure of the active area, the structure of the optical resonator, the structure of the optical waveguide semiconductor, etc., to achieve the effects of reducing reflected energy loss, high output optical power, and large side mode suppression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Silicon-based lasers are the core devices in photonic chips, and play an extremely important role in on-chip optical interconnection and optical switching.

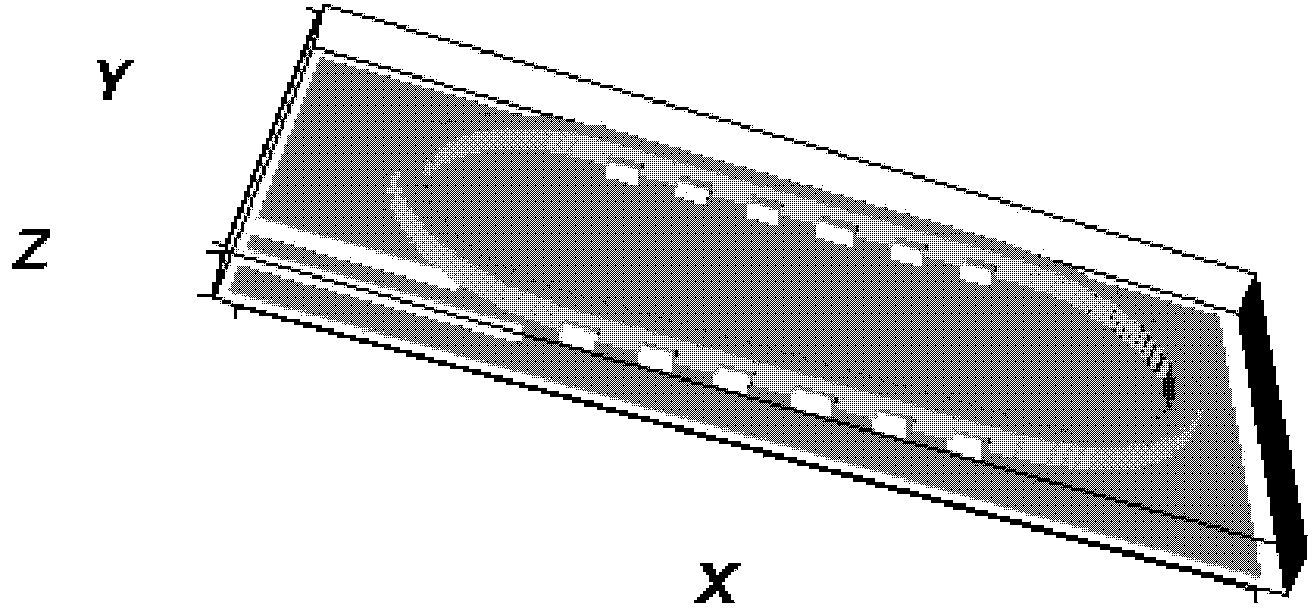

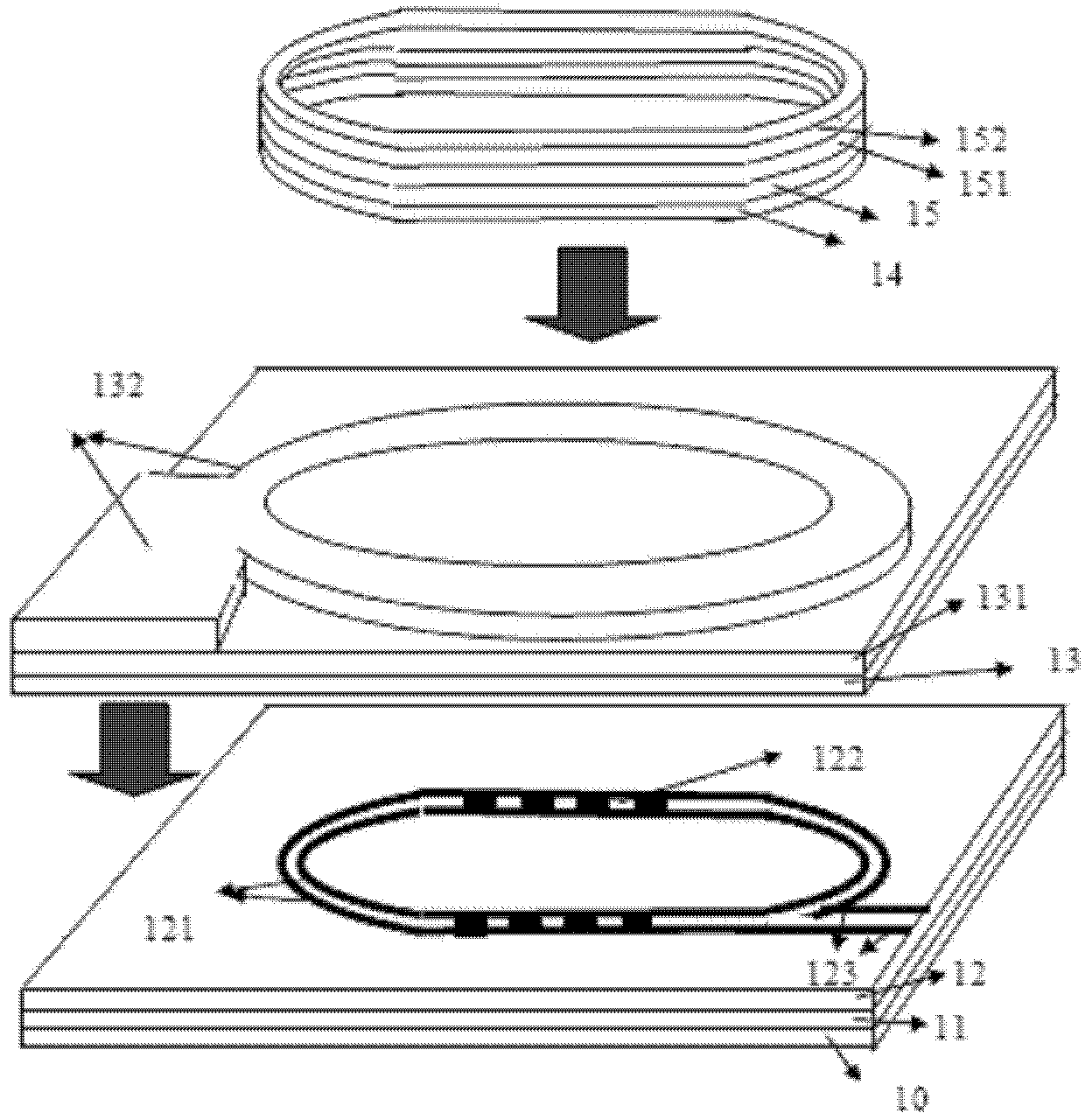

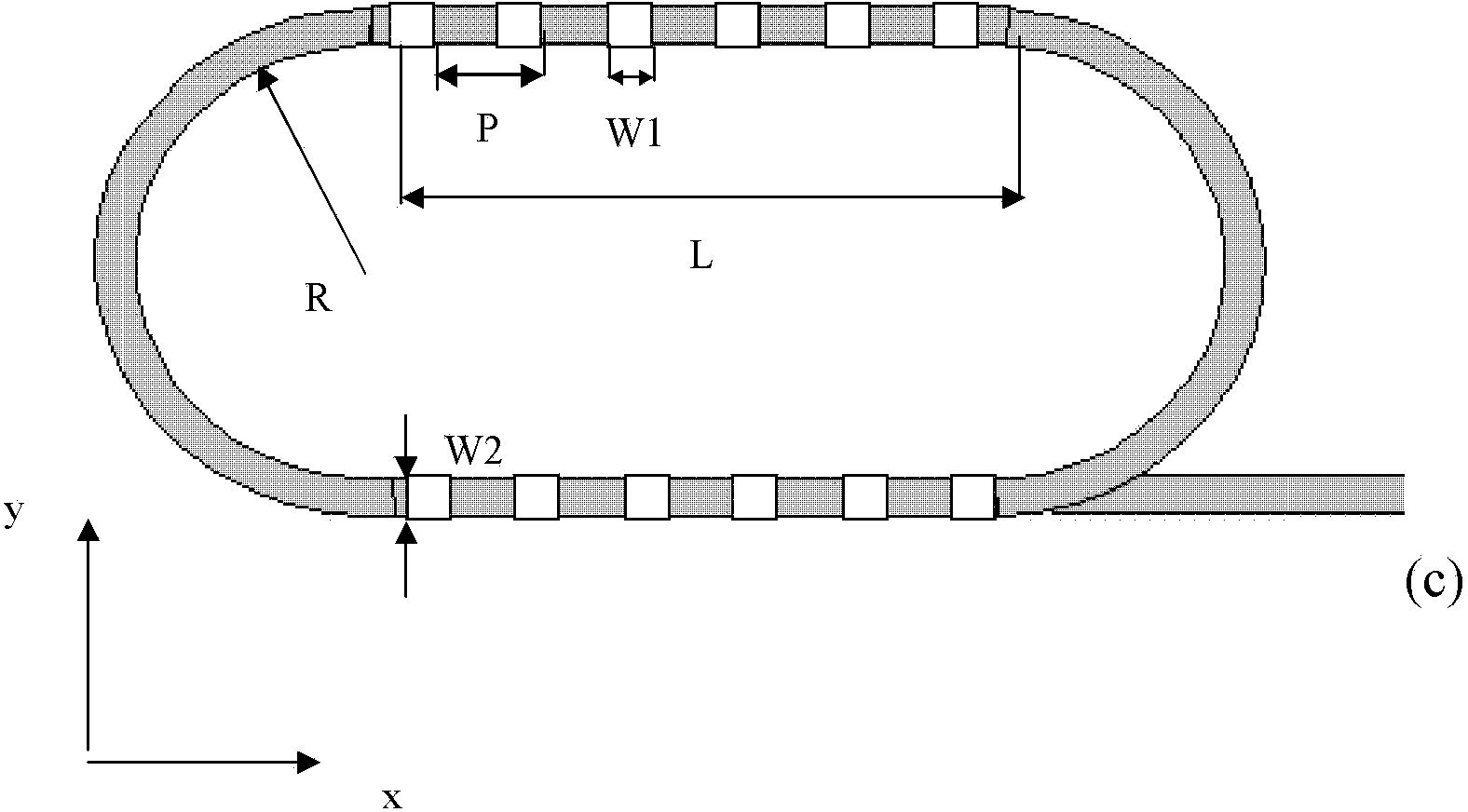

[0027] see figure 1 and figure 2 As shown, the present invention proposes a silicon-based integrated light source with single-mode operating characteristics, which uses a hybrid structure of silicon-based and III-V semiconductor materials. In the case of electrical injection, through evanescent field coupling and silicon-based The single-mode lasing is realized by the annular cavity and periodic microstructure on the surface, and the output light is coupled into the silicon-based waveguide. The gain medium adopts semiconductor multi-quantum well structure, and coplanar electrodes are used to realize electric injection. The III-V capping layer and active multi-quantum well also adopt annular cavity mode, and there can be microstructures on it. The laser is suitable for high-density photonic optoelectronic integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com