High-strength continuous gradient composite scaffold and preparation method thereof

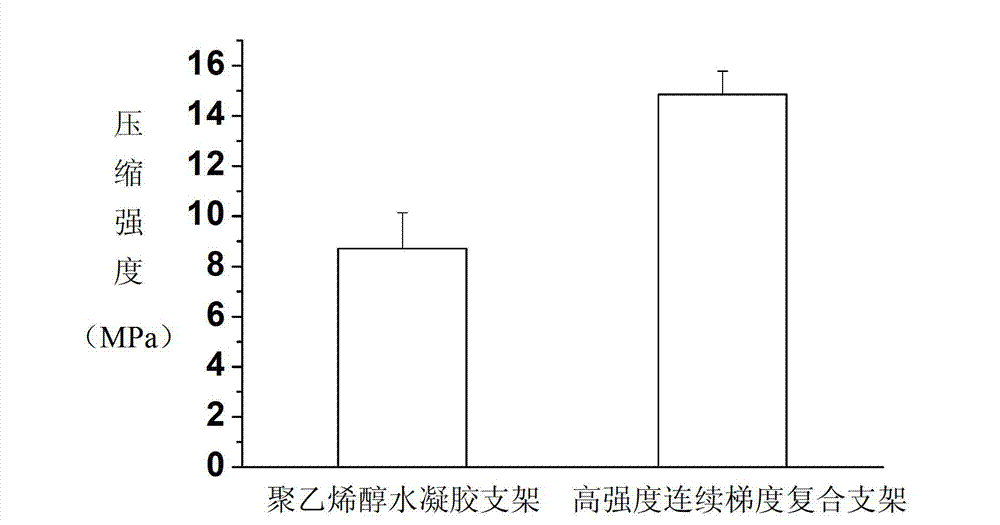

A composite scaffold and high-strength technology, which is applied in the field of biomedical materials and its preparation, can solve problems such as interface defects, achieve high-strength mechanical properties, best mechanical properties and pore diameter, and avoid the effects of interface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0034] γ-Fe 2 o 3 Preparation of / nHAP nanoparticles: using N 2 The method of bubble blowing removes the oxygen dissolved in 30ml deionized water, and then 1.85mmol FeCl 2 4H 2 O and 3.7 mmol FeCl 3 ·6H 2 O was added to the above oxygen-free deionized water until it was completely dissolved to form an aqueous iron salt solution, and the iron salt solution was added to 10ml of NH 4 In OH, 90°C water bath and continuous magnetic stirring 300r / min, after 1h, the generated part is γ-Fe 2 o 3 stock solution of nanoparticles. In part for γ-Fe 2 o 3 In the original solution of nanoparticles, 33.7mmol Ca(NO 3 ) 2 4H 2 O (adjust pH=11) and 20mmol (NH 4 ) 2 HPO 4 (adjust pH = 11), 90 ° C water bath and continuous magnetic stirring 300r / min, after 2 hours, then aging at room temperature for 72 hours to obtain a magnetic composite nanoparticle solution of nano-hydroxyapatite / ferric oxide.

[0035] Place the magnet at the bottom of the beaker containing the magnetic composi...

preparation example 2

[0037] Fe 3 o 4 Preparation of / nHAP nanoparticles: using N 2 The method of bubble blowing removes the oxygen dissolved in 30ml deionized water, and then 1.85mmol FeCl 2 4H 2 O and 3.7 mmol FeCl 3 ·6H 2 O was added to the above oxygen-free deionized water until it was completely dissolved to form an aqueous iron salt solution, and the iron salt solution was added to 10ml of NH 4 In OH, stir magnetically at 300r / min at room temperature 25°C, and Fe will be generated after 1h 3 o 4 Nanoparticle stock solution. in Fe 3 o 4 In the original solution of nanoparticles, 33.7mmol Ca(NO 3 ) 2 4H 2 O (adjust pH=11) and 20mmol (NH 4 ) 2 HPO 4 (adjust pH=11), stir magnetically at 25°C for 300r / min, after 2h, and then age at room temperature for 24h to obtain nano-hydroxyapatite / ferric oxide magnetic composite nanoparticles (Fe 3 o 4 / nHAP) solution.

[0038] Place the magnet at the bottom of the beaker containing the nano-hydroxyapatite / ferric oxide magnetic composite nan...

Embodiment 1

[0040] 1) Dissolve 3.0g of PVA (polymerization degree 1750±50, Sinopharm Chemical Reagent Shanghai Co., Ltd.) in 29.7g of deionized water, heat to dissolve, and obtain 32.7g of polymer solution;

[0041] 2) Disperse 12 g of pure m-nHAP prepared in Preparation Example 1 in 294.3 g of deionized water, and obtain 306.3 g of magnetic composite nanoparticle suspension by ultrasonic dispersion;

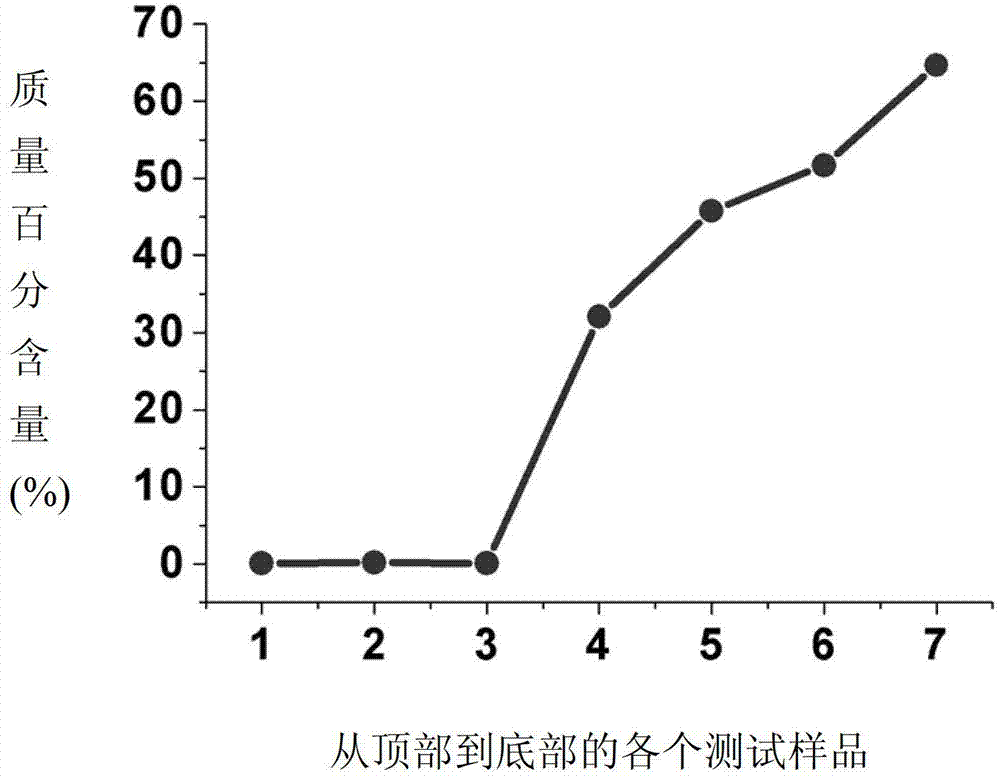

[0042] 3) Mix the polymer solution in step 1) and the magnetic composite nanoparticle suspension in step 2) uniformly to obtain a mixed solution, inject the mixed solution into a mold, and induce it by a magnetic field with a magnetic field strength of 8000 Gauss before gelation The m-nHAP in the mixture was distributed in a continuous gradient for 96 hours, and then the mixture was gelled by cyclic freezing and thawing. In the method of cyclic freezing and thawing, the freezing temperature was -30°C, the freezing time was 15 hours, and the thawing temperature was 25°C, thawing time is 15h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com