Synthetic method of PVC modifier

A synthesis method and modifier technology, which is applied in the synthesis field of PVC modifiers, can solve the problems of large latex particle size, reduced latex stability, and peculiar smell, and achieve pure color, improved impact performance, and reduced haze.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The added raw materials are all calculated in parts by weight.

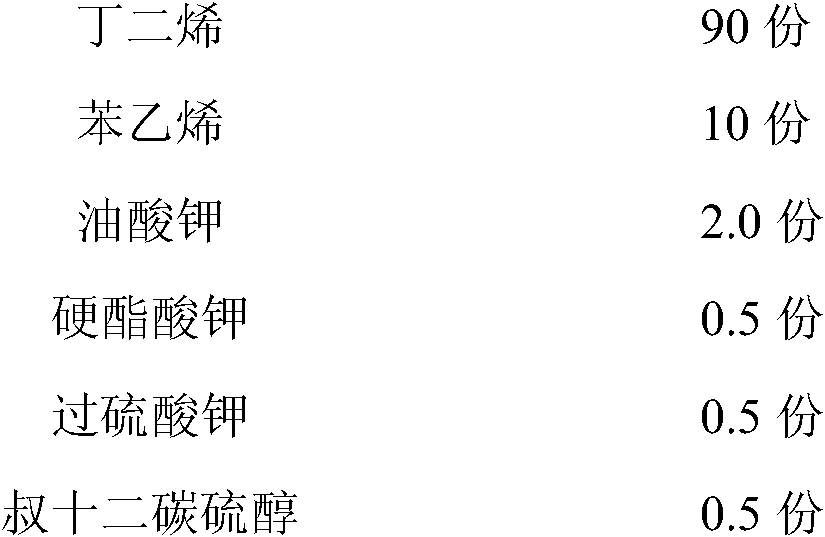

[0028] (1) Synthesis of small particle size styrene-butadiene latex

[0029] Add each material to the reactor in the following proportions:

[0030]

[0031]

[0032] Turn on the stirring and replace with nitrogen twice, then raise the temperature, reach the reaction temperature, keep the temperature and stir and polymerize for 10 hours to obtain a styrene-butadiene latex with a conversion rate of 96.2% and an average particle size of 45 nm.

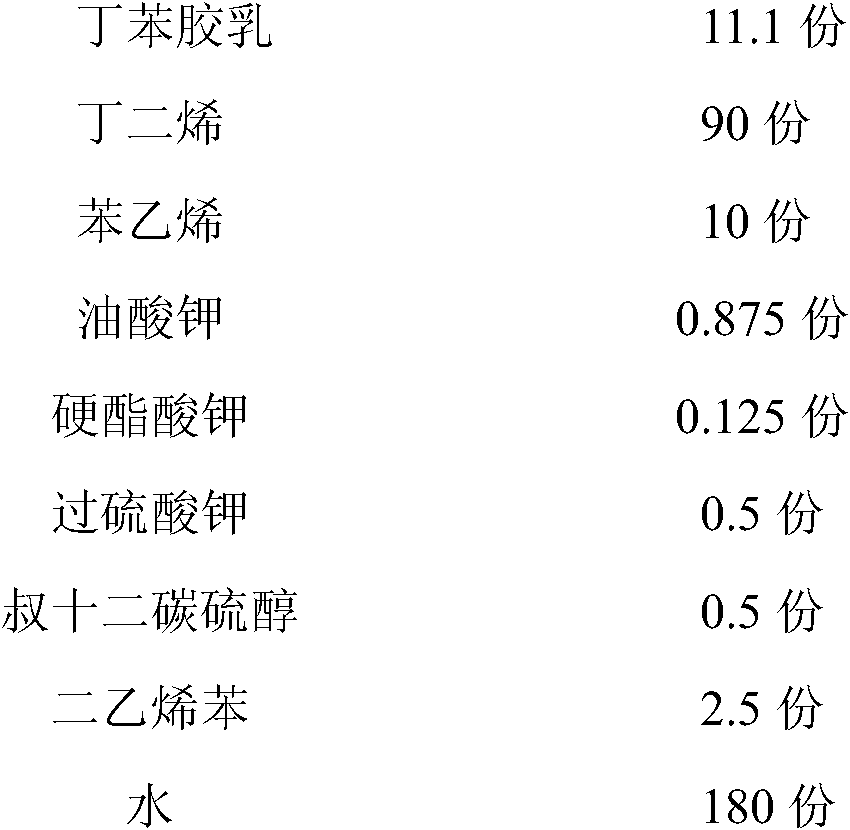

[0033] (2) Synthesis of SBR emulsion with suitable particle size

[0034] Add each material to the reactor according to the following formula:

[0035]

[0036] Turn on the stirring and replace it with nitrogen twice, then raise the temperature, keep the temperature after reaching the reaction temperature, and stir and polymerize for 12 hours to obtain a SBR emulsion with a conversion rate of 94.8% and an average particle size of 105 nm.

[0037] (3) Synt...

Embodiment 2

[0051] Divinylbenzene in the above-mentioned embodiment 1 is all replaced with ethylene glycol dimethacrylate, in the synthetic process of polystyrene-butadiene latex, SBR emulsion, butadiene / styrene weight fraction is changed from original 90 / 10 Change it to 80 / 20, and the rest are identical to Example 1. The performance test results are shown in Table 1.

Embodiment 3

[0053] The emulsifying agent in above-mentioned embodiment 1 is all replaced with sodium lauryl sulfate, in the synthetic process of polymerization MBS resin emulsion, the consumption of SBR emulsion is changed into 80 parts by original 75 parts in the grafting process, styrene is changed into For 12 parts, the first grafting of methyl methacrylate is changed into 2 parts, and the second grafting is changed into 6 parts, and all the other are identical with embodiment 1. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com