A kind of combined processing method of coal tar

A combined processing and coal tar technology, applied in the petroleum industry, hydrotreating process, hydrocarbon oil treatment, etc., can solve the problems of low utilization rate of coal tar, inability to obtain high-quality coke and distillate at the same time, etc. Utilization rate, strong adaptability of raw materials, effect of protective activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

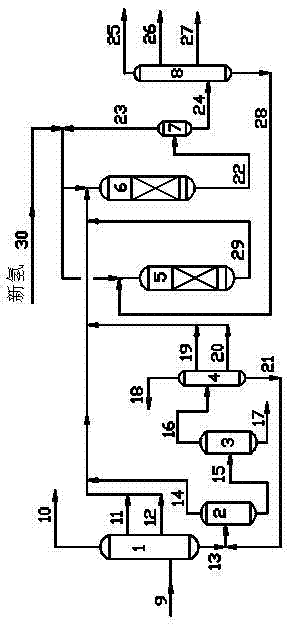

Image

Examples

Embodiment 1

[0021] A medium and low temperature coal tar is used as the feedstock oil. Its properties are shown in Table 1. It is separated by continuous distillation under reduced pressure. Heavy oil fraction at 370°C. The heavy oil distillate at 370°C is used for solvent deasphalting. The solvent used in the solvent deasphalting device is propane, the volume ratio of propane to heavy oil is 3:1, the operating temperature is 65°C, the deasphalted oil obtained after solvent deasphalting is dehydrogenated, the deoiled pitch decoking device, and the operation of the coking tower The temperature is 500°C and the pressure is 1.8Mpa. The coke produced by the coking unit is discharged as a product, and the coking gas and diesel after the separation of the coking produced oil will undergo hydrogenation reaction with other distillates. The reaction conditions of the hydrogenation reaction in the method of the present invention are:

[0022] Hydrofining section: total reaction pressure 14Mpa, spac...

Embodiment 2

[0034] The solvent used in the solvent deasphalting device in this example is isopropanol, and other conditions are the same as in Example 1. The analysis of the 3000-hour operation results is shown in Table 2, Table 3 and Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com