Method for fermenting L-malic acid by utilizing aspergillus flavus

A technology of malic acid and Aspergillus flavus, applied in the field of fermentation, can solve the problems of many by-products, long fermentation period, few research reports, etc., and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This implementation case illustrates the influence of different carbon sources on the production of L-malic acid produced by Aspergillus flavus. Starch, glucose, maltose, sucrose, fructose, mannitol and sorbitol are added as carbon sources respectively, at a temperature of 30°C and a speed of 250 r / min. Fermentation 6 d. The results are shown in Table 1.

[0020] It can be seen from Table 1 that, except for sorbose, all kinds of sugars can be used as a good carbon source, and glucose as a carbon source has the highest acid production.

[0021] Table 1 Effects of different carbon sources on the production of L-malic acid by Aspergillus flavus

[0022] Type of carbon source Concentration (g / L) Residual sugar (g / L) L-malic acid (g / L) starch 60 13.4 32.5 glucose 60 7.6 40.8 maltose 60 14.2 31.1 sucrose 60 34.5 24.1 fructose 60 18.9 26.8 Mannitol 60 46.8 7.8 Sorbitol 60 56.4 2.5

Embodiment 2

[0024] This implementation case illustrates the impact of different nitrogen sources on the production of L-malic acid produced by Aspergillus flavus, adding ammonium chloride 1 g / L, ammonium nitrate 1 g / L, urea 1 g / L, ammonium sulfate 1 g / L, nitric acid Sodium 1 g / L, peptone 5 g / L, corn steep liquor 5 g / L, bean cake powder 5 g / L, adding 60 g / L glucose, temperature 30°C, 250 r / min, and fermented for 6 days. The results are shown in Table 2.

[0025] It can be seen from Table 2 that the effect of using ammonium sulfate, urea and bean cake powder to produce acid is better, and ammonium sulfate is the best nitrogen source in terms of cost.

[0026] Table 2 Effects of different nitrogen sources on the production of L-malic acid by Aspergillus flavus

[0027] Type of nitrogen source Concentration (g / L) Residual sugar (g / L) L-malic acid (g / L) ammonium chloride 1 23.4 32.5 ammonium nitrate 1 22.4 29.6 urea 1 14.2 37.6 ammonium sulfate 1 ...

Embodiment 3

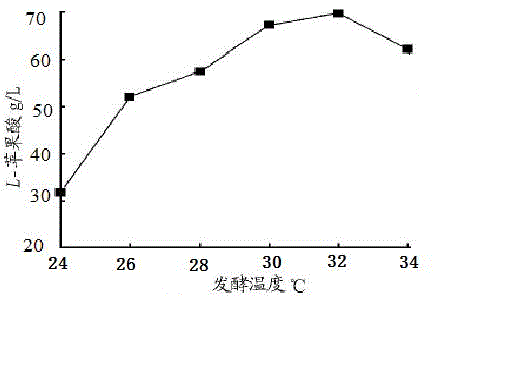

[0029] This implementation case illustrates the effects of different temperatures on the production of L-malic acid produced by Aspergillus flavus. / L of ammonium sulfate at 250 r / min for 6 days of fermentation. The result is as figure 1 shown.

[0030] Depend on figure 1 It can be seen that the yield of L-malic acid increases with the increase of temperature before the temperature is 32°C, and the temperature begins to decrease at 34°C, so the optimum fermentation temperature is selected as 32°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com