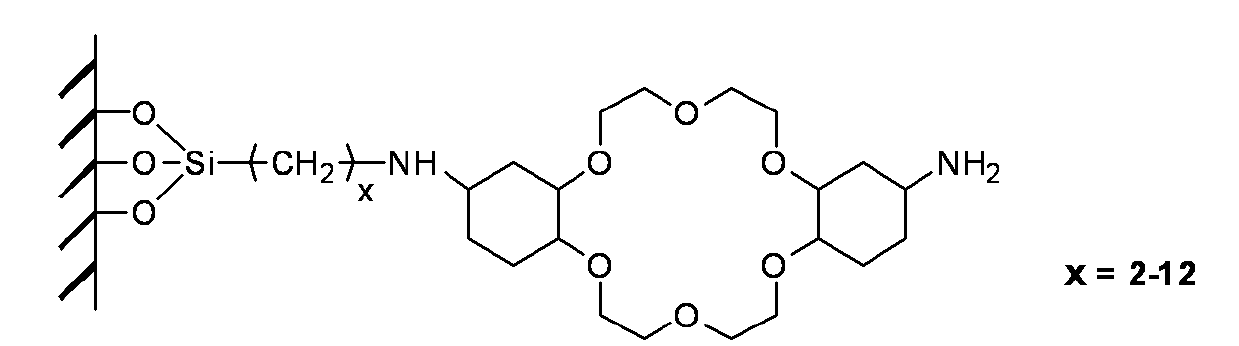

Method for separating lead ions in waste water by utilizing single-arm bonded alicyclic crown ether silicone resin

A silicone resin and alicyclic technology, which is applied in the field of heavy metal ion separation, can solve the problems of crown ether loss, inability to guarantee reusability, etc., and achieves the effects of fast separation speed, excellent thermal stability and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Measure 10 mL of heavy metal wastewater feed solution with a lead ion concentration of 50 ppm into a stoppered glass test tube, add 1.0 g of single-arm bonded alicyclic crown ether silicone resin; place the test tube in a constant temperature water bath at 25 °C, and use After 60 min of electromagnetic stirring, the single-arm bonded cycloaliphatic crown ether silicone resin and heavy metal wastewater were separated by a microporous membrane, and the residual concentration of lead ions in the liquid phase was determined by inductively coupled plasma emission spectrometer (ICP-AES) , the calculated removal rate of lead ions was 97.3%; the isolated one-arm bonded alicyclic crown ether silicone resin was eluted with 0.1mol / L nitric acid solution, washed three times with deionized water, and dried to obtain Recovery of regenerated one-arm bonded alicyclic crown ether silicone resin.

Embodiment 2

[0021] Put 50 mL of feed solution containing heavy metal ions such as copper, zinc, lead, and cadmium in a glass container with a stopper. The concentration of copper, zinc, and cadmium ions in the wastewater sample is 60 ppm, and the concentration of lead ions is 200 ppm; Take 10 g of single-arm bonded alicyclic crown ether silicone resin, add it to the above solution, and put the whole device in a constant temperature shaker at 30°C for 70 min, and then use a microporous filter membrane to separate the single-arm bond. Combined alicyclic crown ether silicone resin and wastewater phase, and measured the residual concentration of lead ions in the water phase, the calculated removal rate of lead ions was 94.8%; the recovered single-arm bonded alicyclic crown ether silicone resin was used 0.05 mol / L nitric acid solution to remove the adsorbed lead ions, and then repeatedly washed with deionized water and dried to realize the regeneration of single-arm bonded alicyclic crown ether...

Embodiment 3

[0023] Take 2 mL of waste water feed solution containing various heavy metal ions in a 5 mL stoppered glass test tube, the feed solution contains 30 ppm copper, 70 ppm zinc, 60 ppm cadmium, and 150 ppm lead; Cyclic crown ether silicone resin and put it into a magnet, put the test tube in a constant temperature water bath at 23°C, and after electromagnetic stirring for 80 minutes, use a microporous membrane to separate the one-arm bonded alicyclic crown ether silicone resin and the wastewater phase ; Measure the residual concentration of lead ions in the water phase by ICP-AES, and calculate the removal rate of lead to be 96.8%; put the isolated one-arm bonded alicyclic crown ether silicone resin into 0.15 mol / L nitric acid solution The adsorbed lead ions were eluted in the medium, followed by repeated washing with deionized water and drying, so as to realize the regeneration of the single-arm bonded alicyclic crown ether silicone resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com