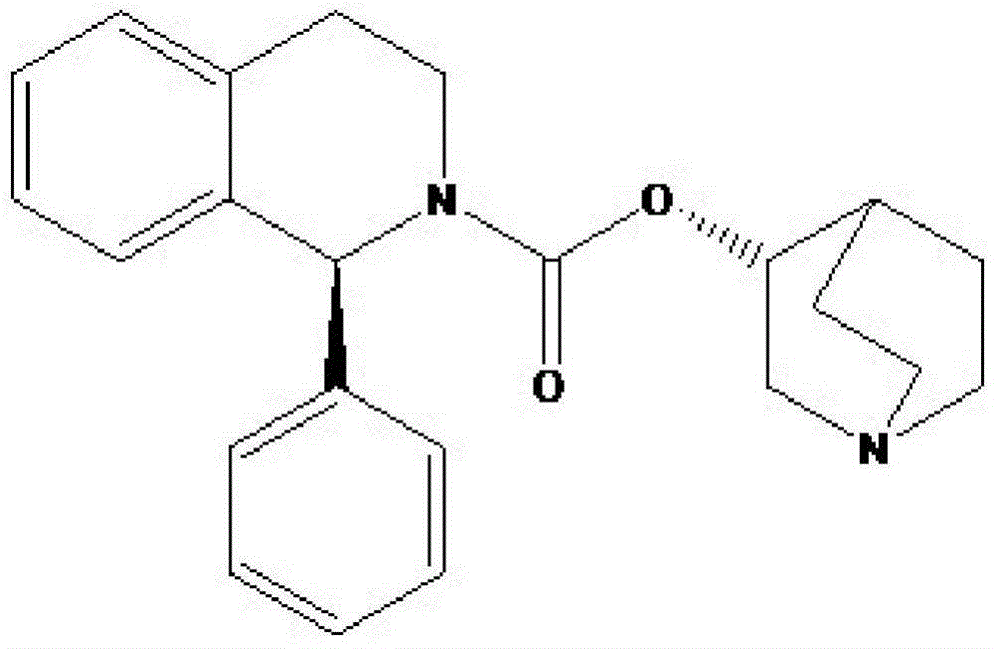

Preparation technology of solifenacin succinate

A technology of solifenacin and solifenacin succinate, applied in the field of medicine, can solve the problems of helpless conversion rate, low transesterification reaction conversion rate, difficult industrialized production, etc., and achieves rapid and mild reaction process. , the effect of increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

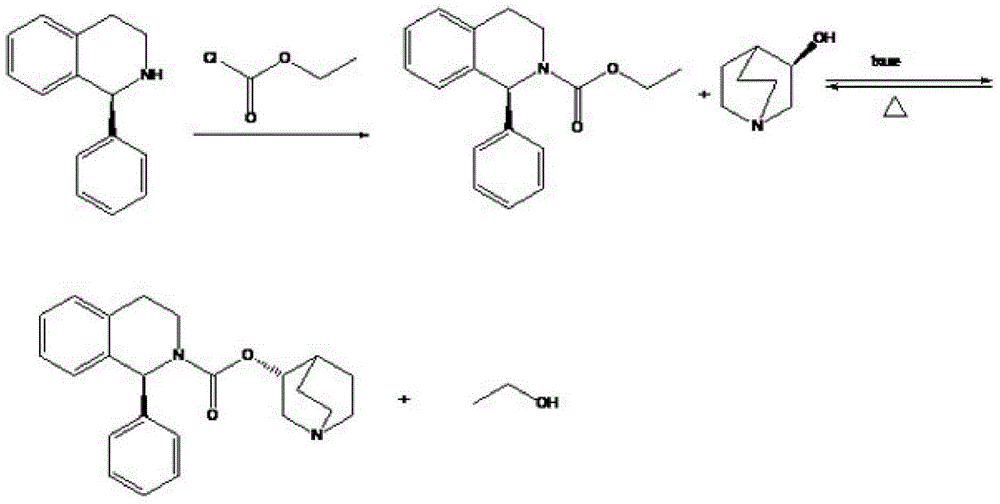

Problems solved by technology

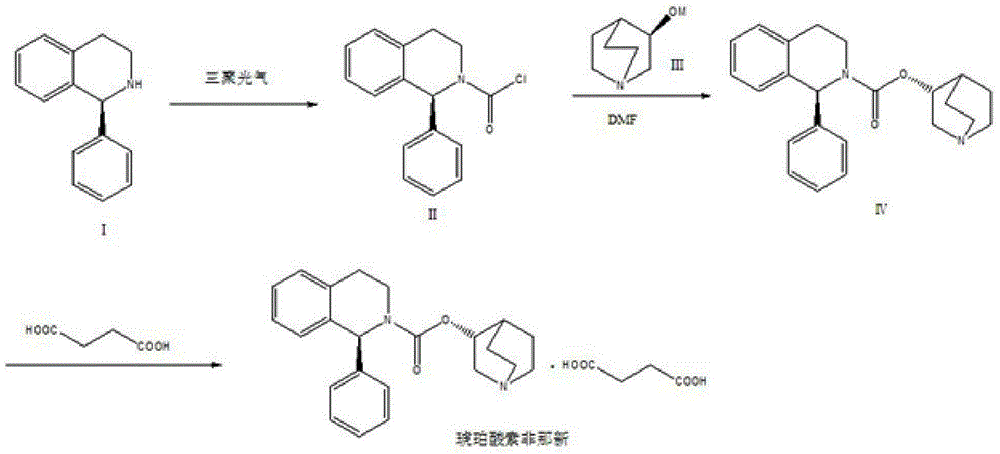

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of Solifenacin Succinate of the present embodiment is as follows:

[0022] 1. First add 10.0g (S)-1-phenyl-1,2,3,4-tetrahydroisoquinoline and 6.3mL triethylamine into 40mL THF (tetrahydrofuran), and drop into the dissolved Add 6.0g of triphosgene to 20mL of toluene solution, add dropwise under ice-water bath, remove the ice-water bath after dropwise addition, and continue to react for 30 minutes. The organic layer was washed twice with 50 mL of water, and concentrated to obtain 12 g of oily (S)-1-phenyl-1,2,3,4-tetrahydroisoquinolinecarbamoyl chloride;

[0023] 2. Add 5.6g (R)-3-quinuclidinol to 50mL DMF (dimethylformamide), stir to dissolve, then add 1.2g sodium hydride in an ice-water bath, stir for 5 minutes after adding, remove Ice-water bath, and continue stirring for 1 hour to obtain a DMF solution of sodium (R)-3-quinuclidinate. Dissolve 12g (S)-1-phenyl-1,2,3,4-tetrahydroisoquinolinecarbamoyl chloride oil in 50mL DMF, and drop the soluti...

Embodiment 2

[0029] The preparation method of Solifenacin Succinate of the present embodiment is as follows:

[0030] 1. First add 10.0g (S)-1-phenyl-1,2,3,4-tetrahydroisoquinoline and 6.3mL N-methylmorpholine into 40mL tetrahydrofuran, and then drop into the dissolved Add 6.0g of phosgene to 20mL of toluene solution, add dropwise under ice-water bath, remove the ice-water bath after dropwise addition, and continue to react for 30 minutes. The organic layer was washed twice with 50 mL of water, and concentrated to obtain 12 g of oily (S)-1-phenyl-1,2,3,4-tetrahydroisoquinolinecarbamoyl chloride;

[0031] 2. Add 5.6g (R)-3-quinuclidinol into 50mL tetrahydrofuran, stir to dissolve, add 2.0g potassium hydride under ice-water bath, stir for 5 minutes after adding, remove the ice-water bath, and continue stirring for 1 hour A DMF solution of potassium (R)-3-quinuclidinate was obtained. Dissolve 12g (S)-1-phenyl-1,2,3,4-tetrahydroisoquinolinecarbamoyl chloride oil in 50mL DMF, and drop the sol...

Embodiment 3

[0037] The preparation process steps in Example 1 were adopted, but the reaction solvent therein was replaced for experimentation, and one solvent component was changed each time.

[0038] (1) (S)-1-phenyl-1,2,3,4-tetrahydroisoquinoline carbamoyl chloride (Ⅱ) reacts with (R)-3-quinuclidinol metal salt (Ⅲ) to form a Phenacin base reaction solvent adopts THF, DMF, dioxane, dichloromethane respectively, and the productive rate of the Solifenacin succinate finally prepared is respectively THF (42%), DMF (58%), dioxane Cyclo(37%), Dichloromethane (31%).

[0039] (2) Synthesis of (R)-3-quinuclidinol metal salt (Ⅲ) is obtained by reacting sodium hydride, potassium hydride and (R)-3-quinuclidinol respectively, and the final prepared solifenacin succinate Yields were consistent. When using DMF as the solvent for condensation, the yields are all about 58%.

[0040] (3) Reaction of (S)-1-phenyl-1,2,3,4-tetrahydroisoquinoline with phosgene, diphosgene or triphosgene to generate (S)-1-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com