Preparation method of peelable type organosilicon pressure-sensitive adhesive

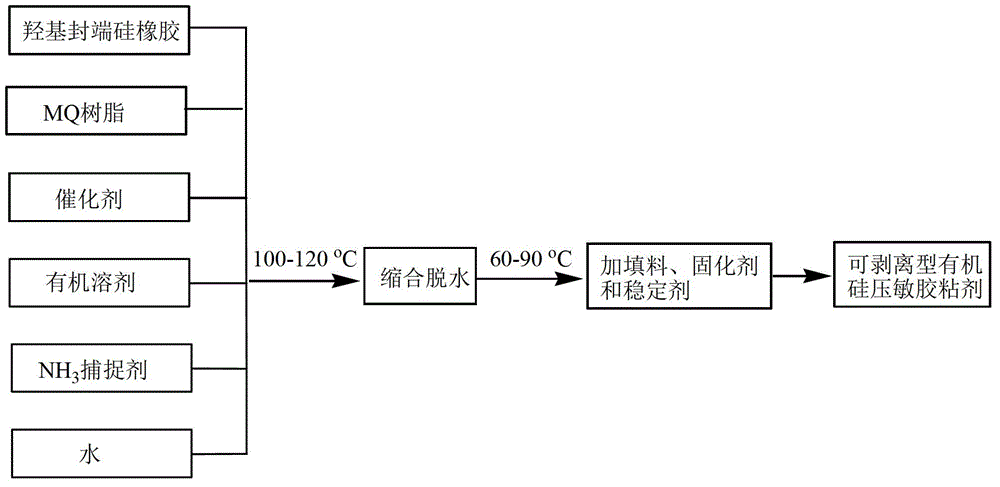

A silicone pressure-sensitive adhesive, pressure-sensitive adhesive technology, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the peelability of peelable silicone pressure-sensitive adhesives, Adhesion, durability and weather resistance requirements are not up to standard, peelability and adhesion are difficult to take into account at the same time, water resistance, durability and weather resistance are general and other problems, to achieve excellent peelability, broad prospects for industrial application, water resistance and The effect of excellent peelability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

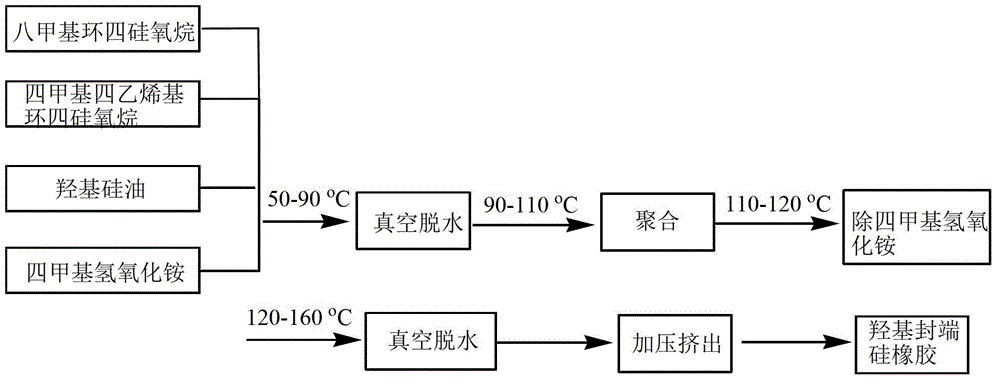

[0028] 55 parts by weight of octamethylcyclotetrasiloxane, 45 parts by weight of tetramethyltetravinylcyclotetrasiloxane, 1.0 parts by weight of 25 o When the viscosity is 200 Pa.s at C, the tetramethylammonium hydroxide of 0.30 weight part adds in the reactor, 60 o C Vacuum dehydration for 0.5 h, remove trace moisture, then pass nitrogen, heat to 95 o C, react for 1 h, raise the temperature to 115°C for further reaction for about 2.5 h, and continue to heat up to 150°C o C and vacuumize to remove low-molecular matter to obtain a hydroxyl-terminated silicone rubber with a molecular weight of 220,000.

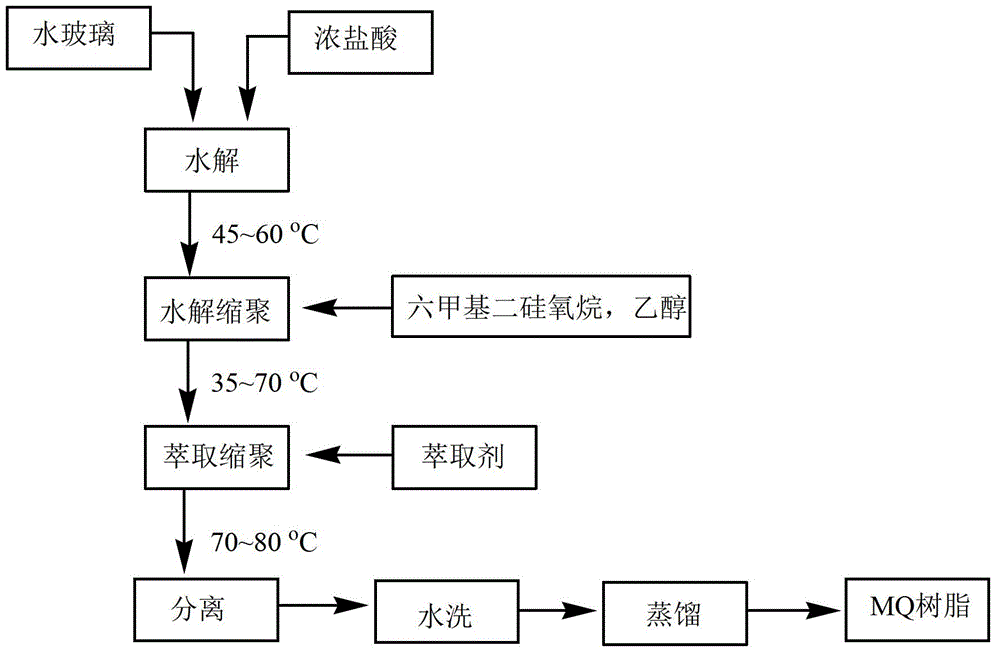

[0029] Add the concentrated hydrochloric acid of 7.5 weight parts in reactor, temperature is 55 o C, the concentration of 55 parts by weight is added rapidly as a 10% aqueous solution of water glass to carry out the hydrolysis reaction, and the hydrolysis time is controlled at 2 min, and then a mixture of 0.5 parts by weight of hexamethyldisiloxane and ...

Embodiment 2

[0034] Same as Example 1, but the amount of hydroxyl-terminated silicone rubber in step (3) changed from 40 to 35, the amount of MQ silicone resin in step (3) changed from 60 to 55, and the others remained unchanged.

Embodiment 3

[0036] Same as Example 1, but the amount of hydroxyl-terminated silicone rubber in step (3) changed from 40 to 43, the amount of MQ silicone resin in step (3) changed from 60 to 57, and the others remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com