Heat-conduction binding material and preparation method thereof

A bonding material and inorganic heat conduction technology, applied in the direction of adhesives, adhesive types, fibrous fillers, etc., can solve the problems of mechanical properties of thermally conductive bonding materials that cannot meet the requirements, organic layer tearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

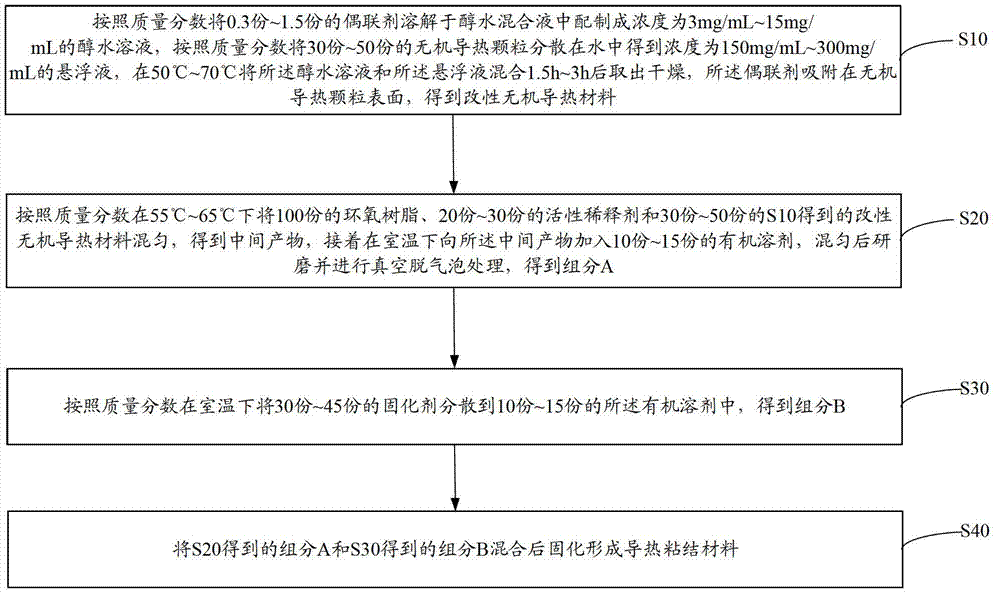

[0054] like figure 1 The preparation method of the above-mentioned thermally conductive bonding material shown includes the following steps:

[0055] S10. According to the mass fraction, dissolve 0.3~1.5 parts of coupling agent in the alcohol-water mixture to prepare an alcohol aqueous solution with a concentration of 3mg / mL~15mg / mL, and mix 30~50 parts of inorganic heat-conducting particles according to the mass fraction Disperse in water to obtain a suspension with a concentration of 150mg / mL~300mg / mL, mix the alcohol aqueous solution and the suspension at 50°C~70°C for 1.5h~3h, take out and dry, and the coupling agent is adsorbed on the inorganic The surface of the heat-conducting particles is modified to obtain a modified inorganic heat-conducting material.

[0056] The alcohol-water mixture can be a mixture of alcohol and water with a volume ratio of 95:5-90:10.

[0057] Drying can be freeze drying or spray drying.

[0058] S20. According to the mass fraction, mix 100 ...

Embodiment 1

[0067] Prepare 1.5 parts of A172 into an alcohol aqueous solution (the volume of the alcohol-water mixture is 100mL, and the alcohol-water volume ratio is 90 / 10), stir and disperse at 300rpm for half an hour, and disperse 50 parts of inorganic heat-conducting particles in water to obtain a concentration of 200mg / mL of the suspension, mix the alcohol aqueous solution and the suspension at 60°C, take it out after 2 hours and spray dry, A172 is adsorbed on the surface of the inorganic heat-conducting particles to obtain a modified inorganic heat-conducting material. In this embodiment, the inorganic heat-conducting particles are 4 parts of Al 2 O 3 , 21 parts of AlN, 18 parts of Si 3 N 4 and 7 parts of thermally conductive graphite powder.

[0068] First heat 60 parts of E51 resin to 60°C, add 40 parts of CY179 resin under stirring, and mix and stir for 0.5h. Then add 25 parts of epoxy hexanediol diglycidyl ether, stir for another 0.5h, stir evenly at 1500rpm, add 50 parts o...

Embodiment 2

[0072] Prepare 0.3 parts of NDZ-401 into an alcohol aqueous solution (the volume of the alcohol-water mixture is 100mL, and the alcohol-water volume ratio is 90 / 10), stir and disperse at 300rpm for half an hour, and disperse 48 parts of inorganic heat-conducting particles in water to obtain the concentration It is a 150mg / mL suspension. Mix the alcohol aqueous solution and the suspension at 50°C, take it out after 2 hours and freeze-dry it. NDZ-401 is adsorbed on the surface of the inorganic heat-conducting particles to obtain a modified inorganic heat-conducting material. In this embodiment, the inorganic heat-conducting particles are 3 parts of Al 2 O 3 , 22 parts of AlN, 16 parts of Si 3 N 4 and 7 parts of thermally conductive graphite powder.

[0073] First heat 65 parts of E51 resin to 55°C, add 35 parts of CY179 resin under stirring, and mix and stir for 0.5h. Then add 25 parts of epoxy hexanediol diglycidyl ether, stir for another 0.5h, stir evenly at 1500rpm, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com