High-capacity double-systematic-circulation cellulose enzymolysis reactor and its application

A technology of cellulase and reactor, which is applied in the direction of enzyme production/bioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., which can solve the problems of short time consumption, low enzyme consumption, Difficulty in the enzymatic hydrolysis process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125] enzymatic saccharification

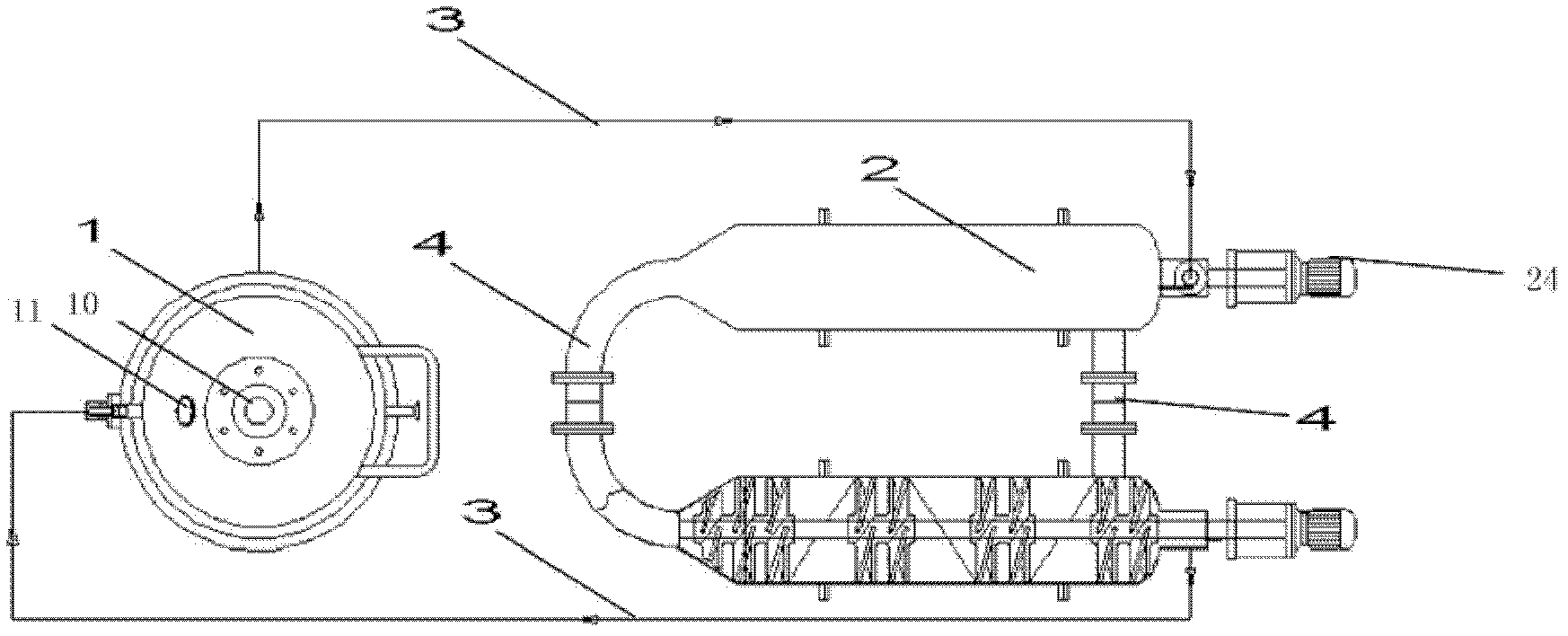

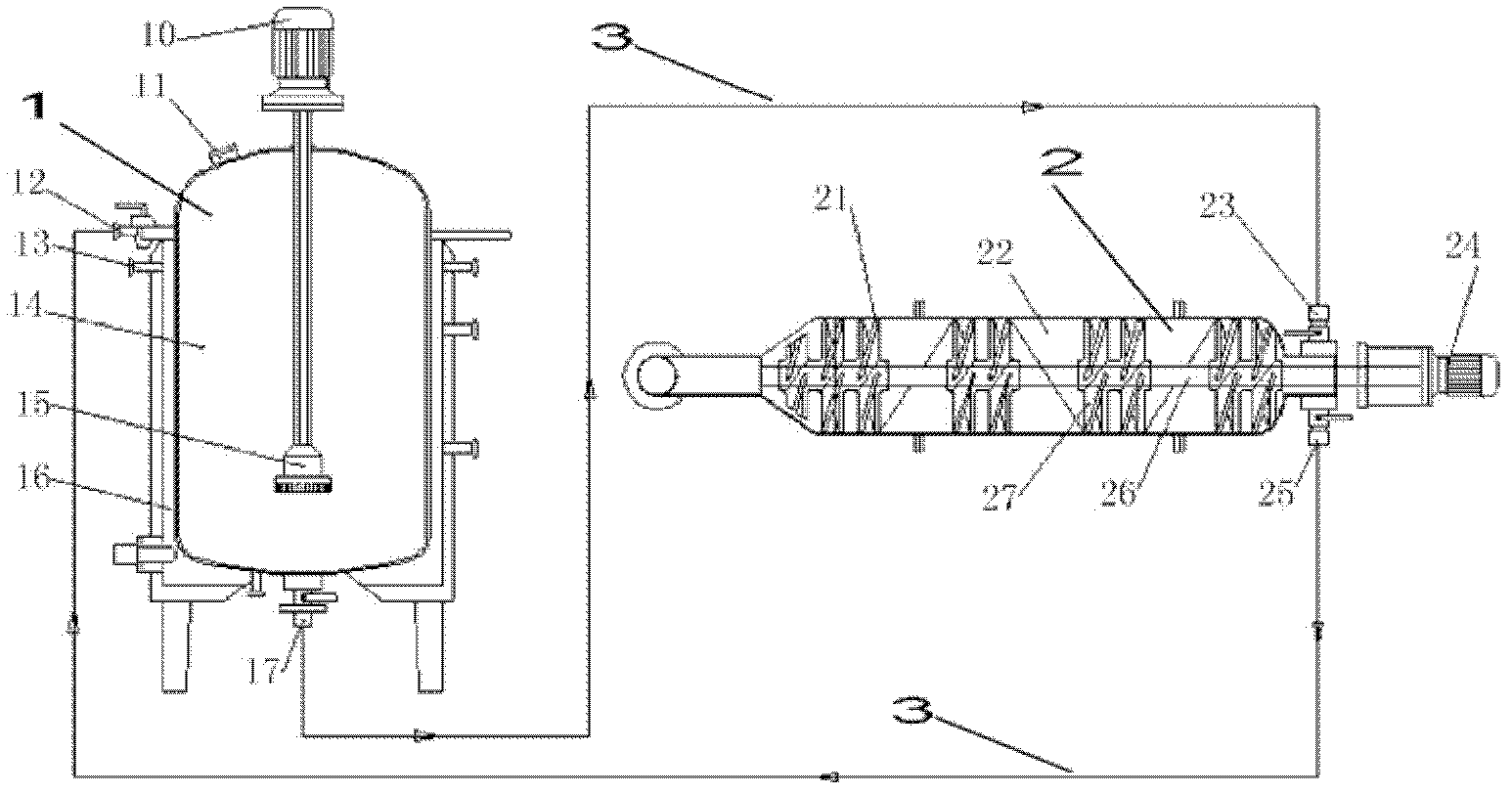

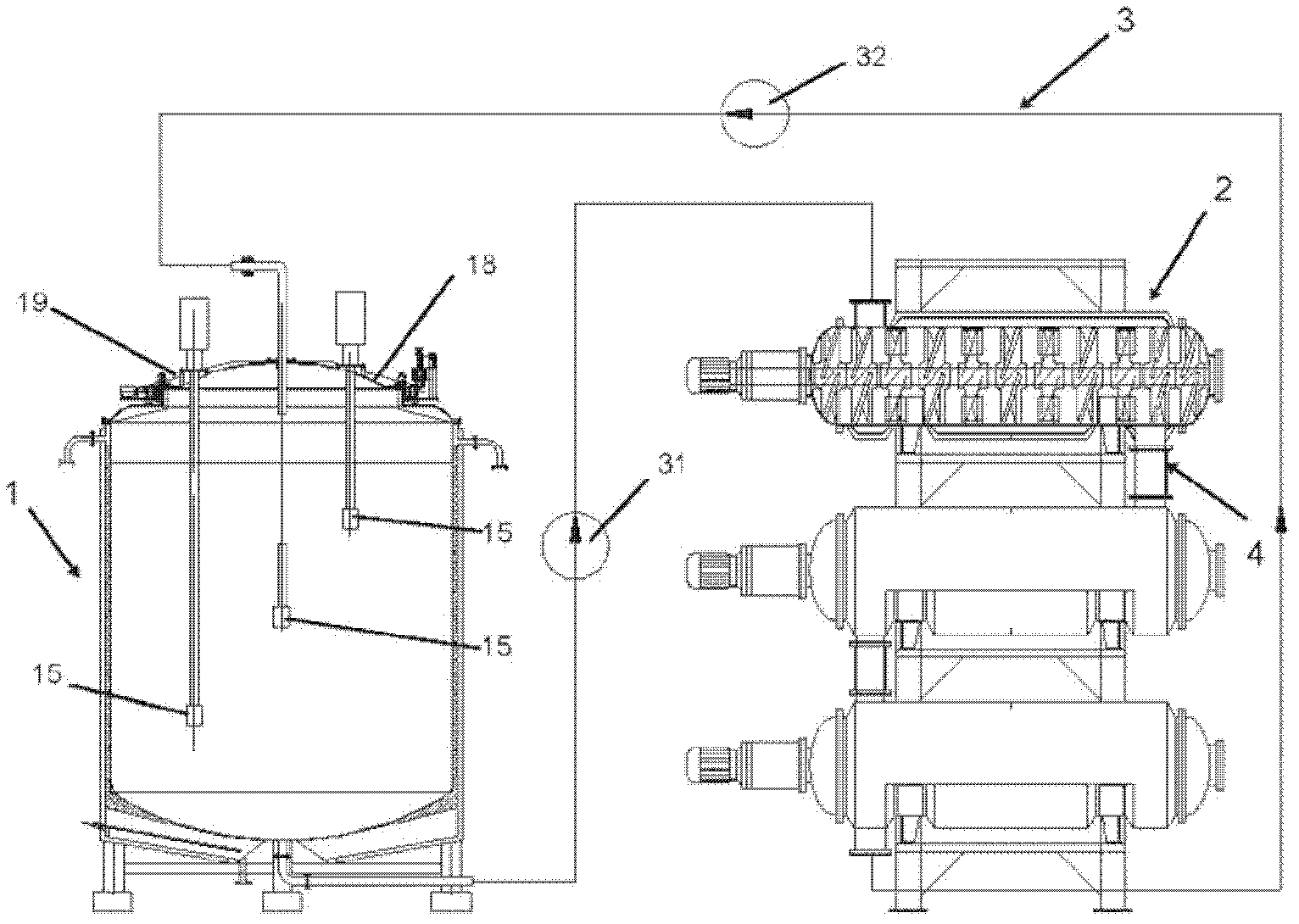

[0126] use figure 1 The enzymatic saccharification device shown performs enzymatic saccharification according to the following steps:

[0127] 1. Steps:

[0128] 1.1 The slurry solution after pretreatment is prepared into a 100L solution with a substrate concentration of 6%.

[0129] 1.2 Dissolve an appropriate amount of citric acid and trisodium citrate in the solution, and adjust the pH value to 4.8.

[0130] 1.3 Heat the jacket of the two-body cycle enzymolysis reactor to 50°C;

[0131] 1.4 Add 75% of the total amount of cellulase (enzyme can be liquid enzyme and / or solid enzyme) into the solution, and position the reaction start time at 0 o'clock at this time. Wherein the total consumption of cellulase (including endoglucanase, exoglucanase and β-glucosidase) is 1000IU / ml. The slurry solution is poured into the first reaction tank at a speed of 600rpm, and from the first reaction tank into the second reaction tank at a speed of 50rp...

Embodiment 2

[0141] use figure 1 The enzymatic saccharification device shown performs enzymatic saccharification according to the following steps:

[0142] 1. Steps:

[0143] 1.1 The slurry solution after pretreatment is prepared into a 100L solution with a substrate concentration of 6%.

[0144] 1.2 Dissolve an appropriate amount of citric acid and trisodium citrate in the solution, and adjust the pH value to 4.8.

[0145] 1.3 Heat the jacket of the two-body cycle enzymolysis reactor to 50°C;

[0146] 1.4 Add 75% of the total amount of cellulase (enzyme can be liquid enzyme and / or solid enzyme) into the solution, and position the reaction start time at 0 o'clock at this time. Wherein the total consumption of cellulase (including endoglucanase, exoglucanase and β-glucosidase) is 900IU / ml. The slurry solution is poured into the first reaction tank with a rotating speed of 1500rpm, and from the first reaction tank into the second reaction tank with a rotating speed of 120rpm. All the ma...

Embodiment 3

[0156]use figure 1 The enzymatic saccharification device shown performs enzymatic saccharification according to the following steps:

[0157] 1. Steps:

[0158] 1.1 The slurry solution after pretreatment is prepared into a 100L solution with a substrate concentration of 6%.

[0159] 1.2 Dissolve an appropriate amount of citric acid and trisodium citrate in the solution, and adjust the pH value to 4.8.

[0160] 1.3 Heat the jacket of the two-body cycle enzymolysis reactor to 50°C;

[0161] 1.4 Add 75% of the total amount of cellulase (enzyme can be liquid enzyme and / or solid enzyme) into the solution, and position the reaction start time at 0 o'clock at this time. Wherein cellulase is acid cellulase, and the total consumption is 1200IU / ml. The slurry solution is poured into the first reaction tank at a speed of 2800rpm, from the first reaction tank into the second reaction tank at a speed of 250rpm. All the materials carry out two-body circulation between the first reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com