Method for preparing fructose syrup

A technology of fructose syrup and glucose glucoamylase, applied in the field of preparation of fructose syrup, can solve the problems of high preparation cost, large energy consumption, and large heat energy consumption, achieve product quality safety, reduce total energy consumption, and reduce production capacity consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

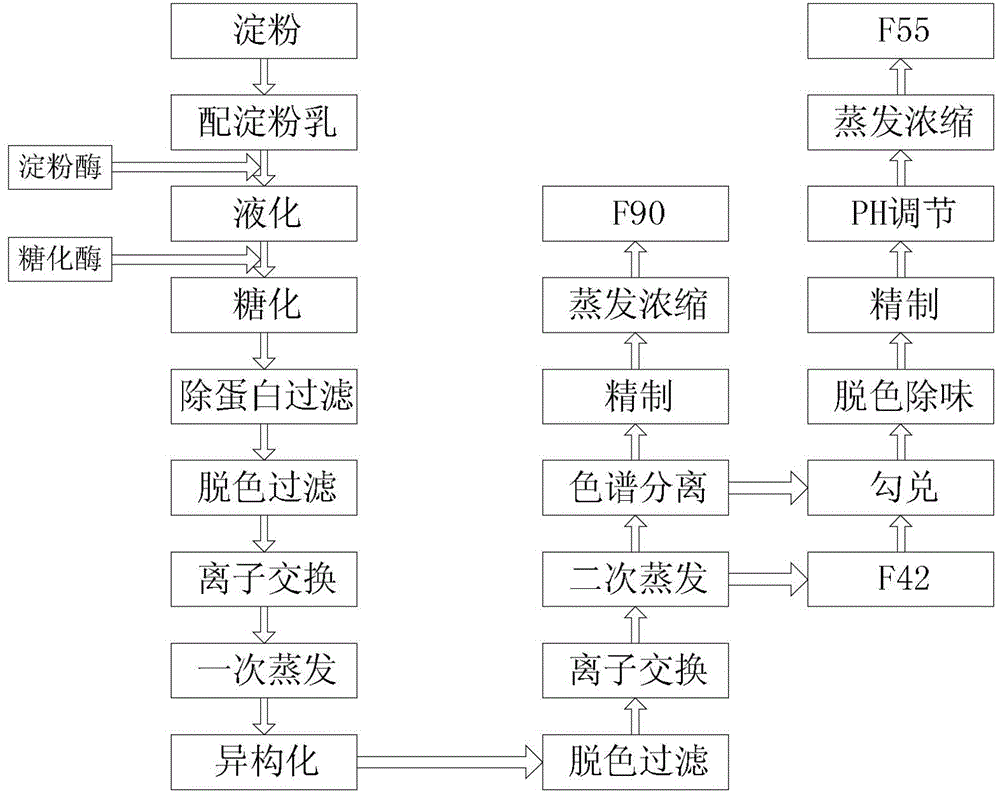

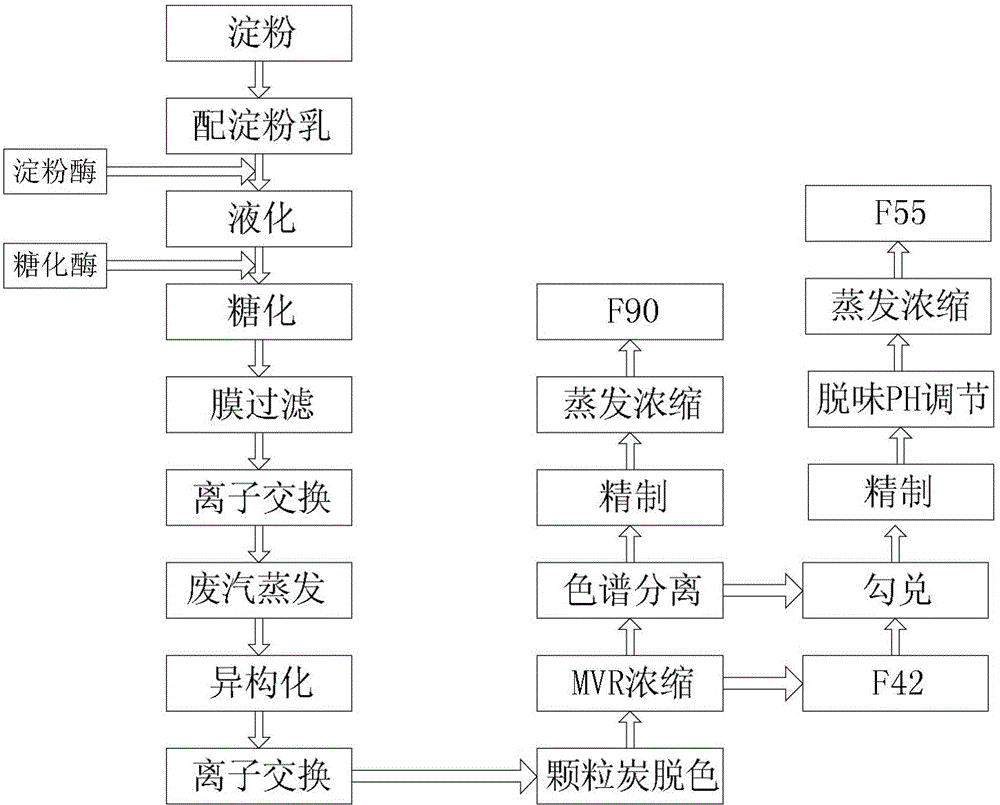

[0028] Such as figure 2 For the process flow diagram of the production of fructose syrup of the present embodiment, the detailed steps are as follows:

[0029] 1. Starch is prepared into starch milk of 18 degrees Baume (°Be'), and the concentration of 10% Na is 2 CO 3 The solution adjusts the pH value of the starch milk to 5.7-6.0. Calculated based on the dry matter of the starch milk, add 0.23kg / t α-amylase, spray and liquefy at a high temperature of 105-108°C, and hydrolyze for 15-30min until the DE value of the system liquid is 11%. Transport the reaction liquid to the flash tank (vacuum degree is 0.01MPa) to obtain a liquefied liquid at 58-60°C, and collect the waste heat of the flash steam (97°C) in the flash tank for later use;

[0030]2. Use 10% hydrochloric acid by mass to adjust the pH of the liquefied liquid to 4.2-4.4, add 0.36 kg / t of glucose glucoamylase according to the dry matter of the liquefied liquid, and carry out the saccharification reaction at 58-60°C ...

Embodiment 2

[0037] 1, the starch is mixed with the starch milk of 23 Baume degrees (°Be '), be 10% Na with mass percent concentration 2 CO 3 Adjust the pH value of the starch milk to 5.7-6.0 with the solution, add 0.35kg / t of α-amylase according to the dry matter of the starch milk, spray and liquefy at a high temperature of 105-108°C, and hydrolyze for 15-30min until the DE value of the system liquid is 11% , transport the reaction liquid to the flash tank (vacuum degree is 0.02MPa) to obtain a liquefied liquid at 58-60°C, and collect the waste heat of the flash steam in the flash tank (95°C) for standby;

[0038] 2. Adjust the pH value of the liquefied liquid to 4.2-4.4 with hydrochloric acid with a concentration of 10% by mass, add 0.36kg / t of glucose glucoamylase according to the dry matter of the liquefied liquid, and carry out the saccharification reaction at 60-62°C, and the saccharification time After 28 hours, when the DX value of the feed liquid reaches 98%, the material is dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com