Direct acidity oxygen pressure leaching treatment method of crude tin copper removal residues

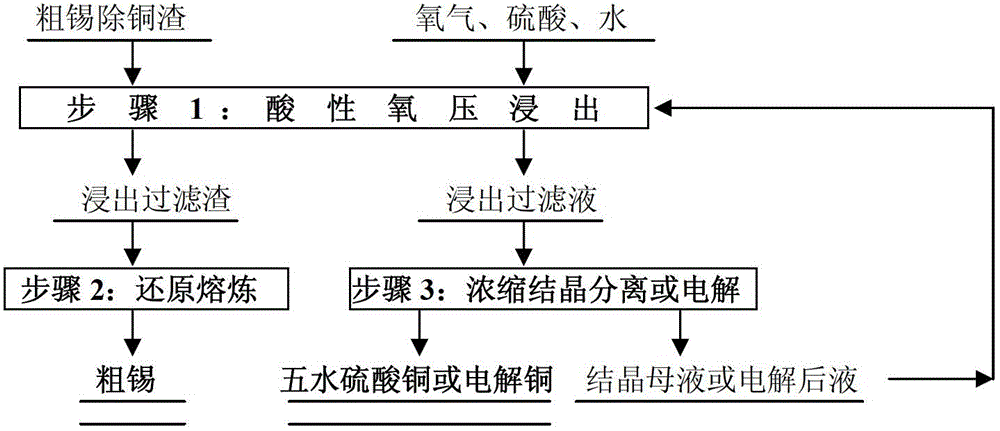

A technology of oxygen pressure leaching and treatment method, which is applied in the field of direct acid oxygen pressure leaching treatment of crude tin copper removal slag, which can solve the problems of metal loss, long process flow and high production cost, and achieve rapid separation, short process flow and direct recovery high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0019] Present embodiment is the first example of the processing method of thick tin copper slag of the present invention, comprises the steps:

[0020] (1) Acidic oxygen pressure leaching: add 3 tons of crude tin decopper slag containing 55% tin and 18% copper, add 15 cubic meters of leaching solution with an initial acidity of 100 g / l, at a temperature of 120°C and an oxygen partial pressure Under the condition of 0.15MPa, it was leached in a 20 cubic meter autoclave for 6 hours; The filtrate is 14 cubic meters, and the output is 3.5 tons of filter residue with a water content of 32%, a tin content of 70.3%, and a copper content of 2.5%. The direct recovery rate of copper is 88.1%, and the direct recovery rate of tin is 99.7%.

[0021] (2) Reduction smelting of filter residues: Mix 3.5 tons of filter residues with 0.5 tons of reduced coal, carry out reduction smelting at a temperature of 1250°C for 6 hours, and produce 1.51 tons of crude tin containing 92.6% tin and 3.4% cop...

no. 2 example

[0024] Present embodiment is the second example of the processing method of thick tin copper slag of the present invention, comprises the steps:

[0025] (1) Acidic oxygen pressure leaching: Add 3 tons of crude tin decopper slag containing 65% tin and 13% copper, add 15 cubic meters of leaching solution with an initial acidity of 150 g / l, at a temperature of 135°C and an oxygen partial pressure Under the condition of 0.20MPa, it was leached in a 20 cubic meter autoclave for 5 hours; The filtrate is 13.8 cubic meters, and the output is 3.8 tons of filter residue containing 31% water, 74.3% tin, and 1.7% copper; the direct recovery rate of copper is 88.4%, and the direct recovery rate of tin is 99.8%.

[0026] (2) Reduction smelting of filter residues: Mix 3.8 tons of filter residues with 0.5 tons of reduced coal, carry out reduction smelting at a temperature of 1260°C for 6 hours, and produce 1.82 tons of crude tin containing 93.4% tin and 2.3% copper.

[0027] (3) Filtrate co...

no. 3 example

[0029] Present embodiment is the 3rd example of the processing method of thick tin copper slag removal described in the present invention, comprises the steps:

[0030] (1) Acidic oxygen pressure leaching: add 4 tons of crude tin decopper slag containing 75% tin and 8% copper, and add 16 cubic meters of leaching solution with an initial acidity of 150 g / L. Under the condition of 0.25MPa, it was leached in a 20 cubic meter autoclave for 4 hours; after the leaching, it was filtered, and the final acid of the output was 118 grams per liter, containing 20 grams per liter of copper and 0.72 grams per liter of tin. The filtrate is 14.4 cubic meters, and the output is 5.2 tons of filter residue containing 30% water, 82.1% tin, and 0.88% copper; the direct recovery rate of copper is 90.0%, and the direct recovery rate of tin is 99.6%.

[0031] (2) Reduction smelting of filter residue: Mix 5.2 tons of filter residue with 0.7 tons of reduced coal, carry out reduction smelting at a tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com