Method for preparing organic pigment microcapsule polyester color yarn

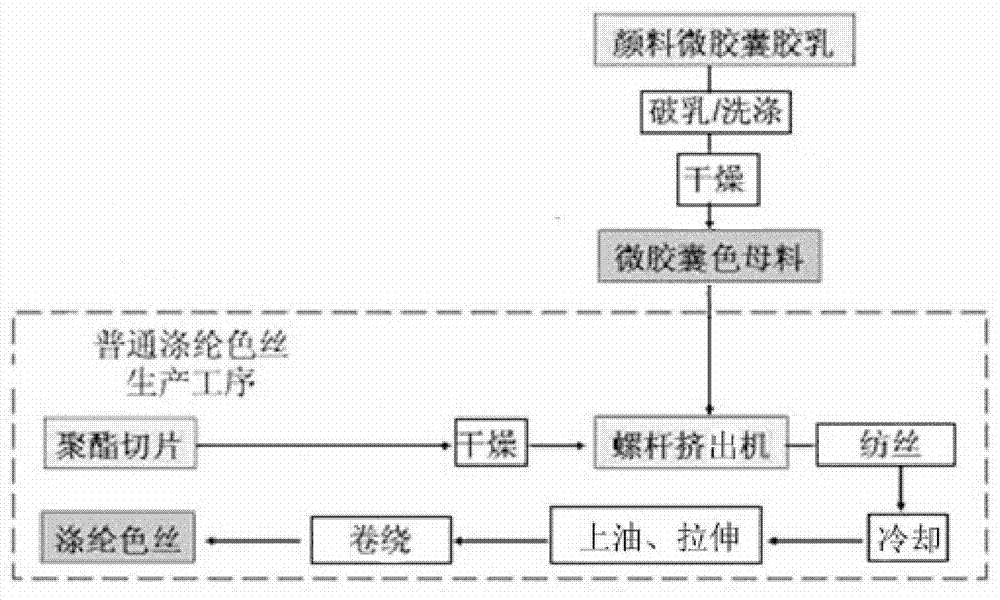

A technology of organic pigments and microcapsules, which is applied in the manufacture of rayon, single-component polyester rayon, and fiber chemical characteristics, to achieve the effects of easy implementation, simple process, and convenient color development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~24

[0048] Mix and stir the organic pigment (according to the content of the organic pigment in the organic pigment microcapsule), 0.5 g co-emulsifier hexadecane, 1.0 g polymerized monomer styrene (St) and butyl acrylate (BA) to obtain a pigment / unit body mixture; add oil-soluble crosslinking agent divinylbenzene (DVB) and initiator azobisisobutylcyanide (AIBN) 2.0g to the pigment / monomer mixture, stir well and then add emulsifier dodecane Sodium disulfate (SDS) 1.5g and the balance of deionized water (based on the total amount of the mixture 100g), after pre-emulsification for 10min, the pigment / monomer fine emulsion was obtained by ultrasonic dispersion; the pigment / monomer fine emulsion was Polymerize under nitrogen atmosphere at 73°C and 150rpm shear stirring rate for 6 hours, cool after the reaction, and obtain a series of organic pigment microcapsule latex (referred to as: pigment Microcapsule latex), the test results are shown in Table 1. The remaining raw material consump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com