Method for preparing multi-wavelength silica-based hybrid laser array by changing width of silicon waveguide

A hybrid laser and laser array technology, which is applied to semiconductor laser devices, laser devices, structures of optical waveguide semiconductors, etc., can solve the problems of increased manufacturing cost, process difficulty, and high requirements for process alignment accuracy, and achieves low cost, low process technology, and the like. Simple, easy to achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

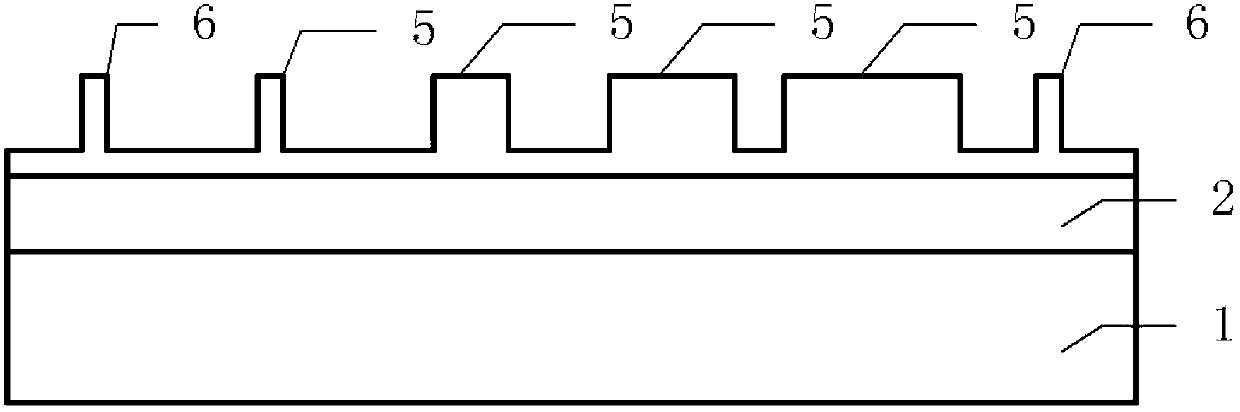

[0021] see figure 1 and refer to Figure 2-Figure 8 As shown, a method for preparing a multi-wavelength silicon-based hybrid laser array by changing the width of the silicon waveguide of the present invention is described in detail.

[0022] The following takes the 4-wavelength silicon-based hybrid laser array as an example to introduce the specific implementation scheme:

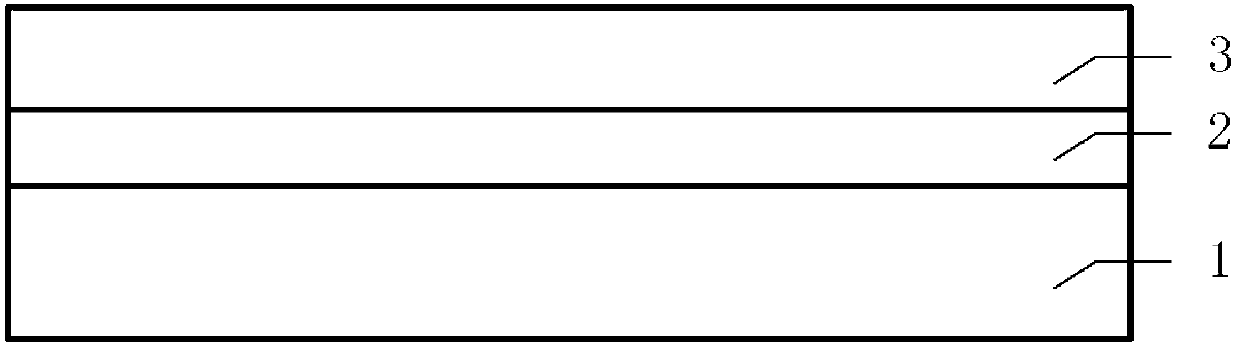

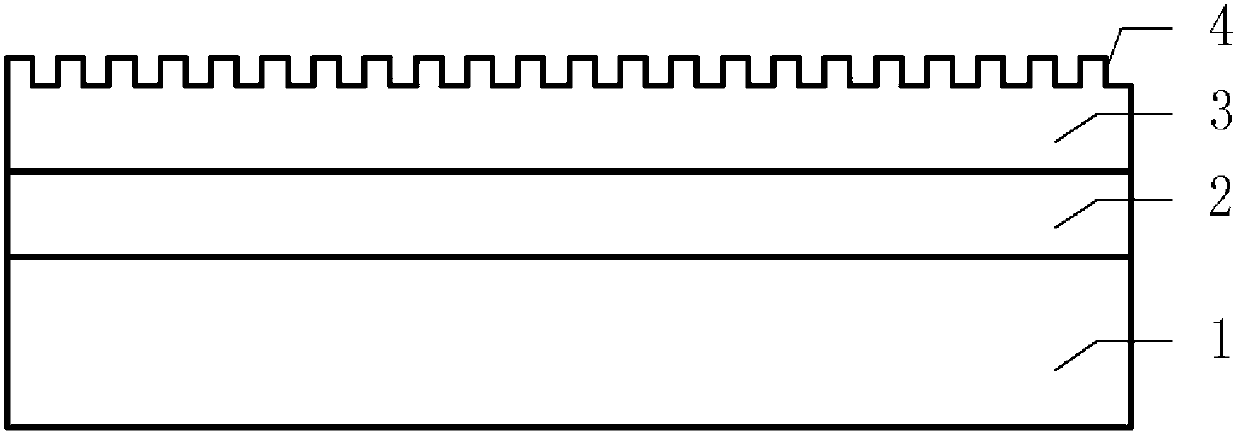

[0023] Step 1: On the SOI sheet (see figure 2 ) (silicon crystal 1, silicon oxide layer 2, silicon layer 3) on the top silicon layer 3 using holographic exposure method and reactive ion etching (RIE) etching technology to make a uniform grating 4 ( refer to image 3 ), the grating period Λ=λ / 2n of the grating 4 eff , n eff is the effective refractive index of the device, λ is the target wavelength of the laser, generally 1.31 μm or 1.55 μm in the optical communication band, and the duty ratio is 1:1. CF4 is used as the dry etching gas, and the grating is produced by holographic exposure. The process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com