Improved digestion of biosolids in wastewater

A technology of biosolids and anaerobic digestion, which is applied in the field of systems to improve the biodigestion process, and can solve problems such as high infrastructure and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0054] The effectiveness of using chlorine dioxide to reduce pathogen and heterotrophic bacterial populations in municipal sludge was evaluated.

[0055] The use of chlorine dioxide to treat non-digested wastewater sludge can reduce the concentration of fecal coliform bacteria to a level far below the level B standard (<2,000,000 fecal coliform bacteria) within a contact time of less than 15 minutes, which can make the Material meets Class B pathogen reduction requirements prior to digestion. The resulting block of biosolids has no malodor. Examples of fecal coliform reduction at different chlorine dioxide dose rates are listed in Table 1.

[0056] Table 1. Test results of real condition of secondary sludge

[0057]

[0058] *below detection limit

[0059] In this test, chlorine dioxide was generated on-site and injected (at various concentrations) into 100 gpm of sludge flowing through a 4 inch diameter pipe. The pipe length is sufficient to allow a contact time of 10 ...

example 2

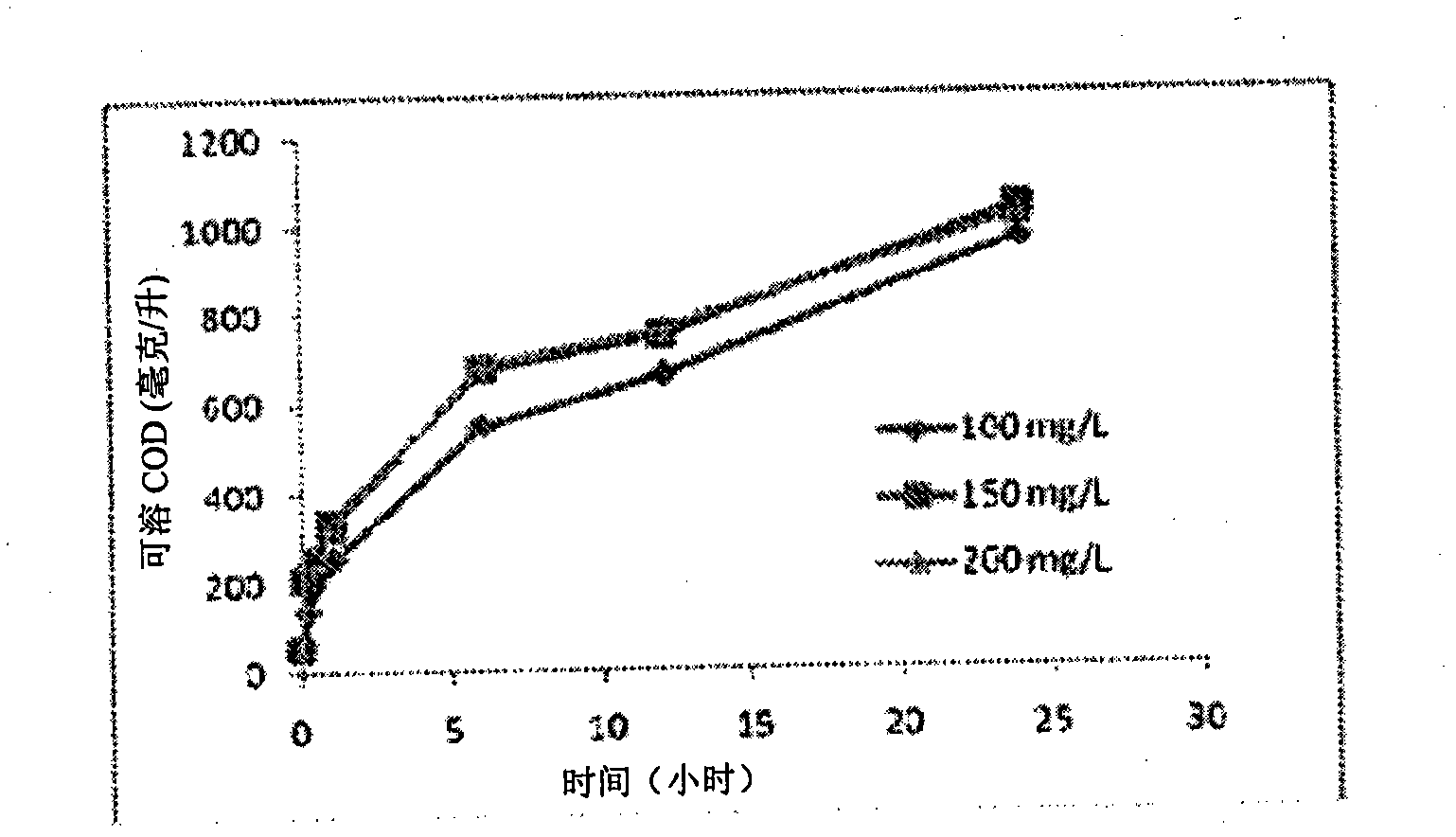

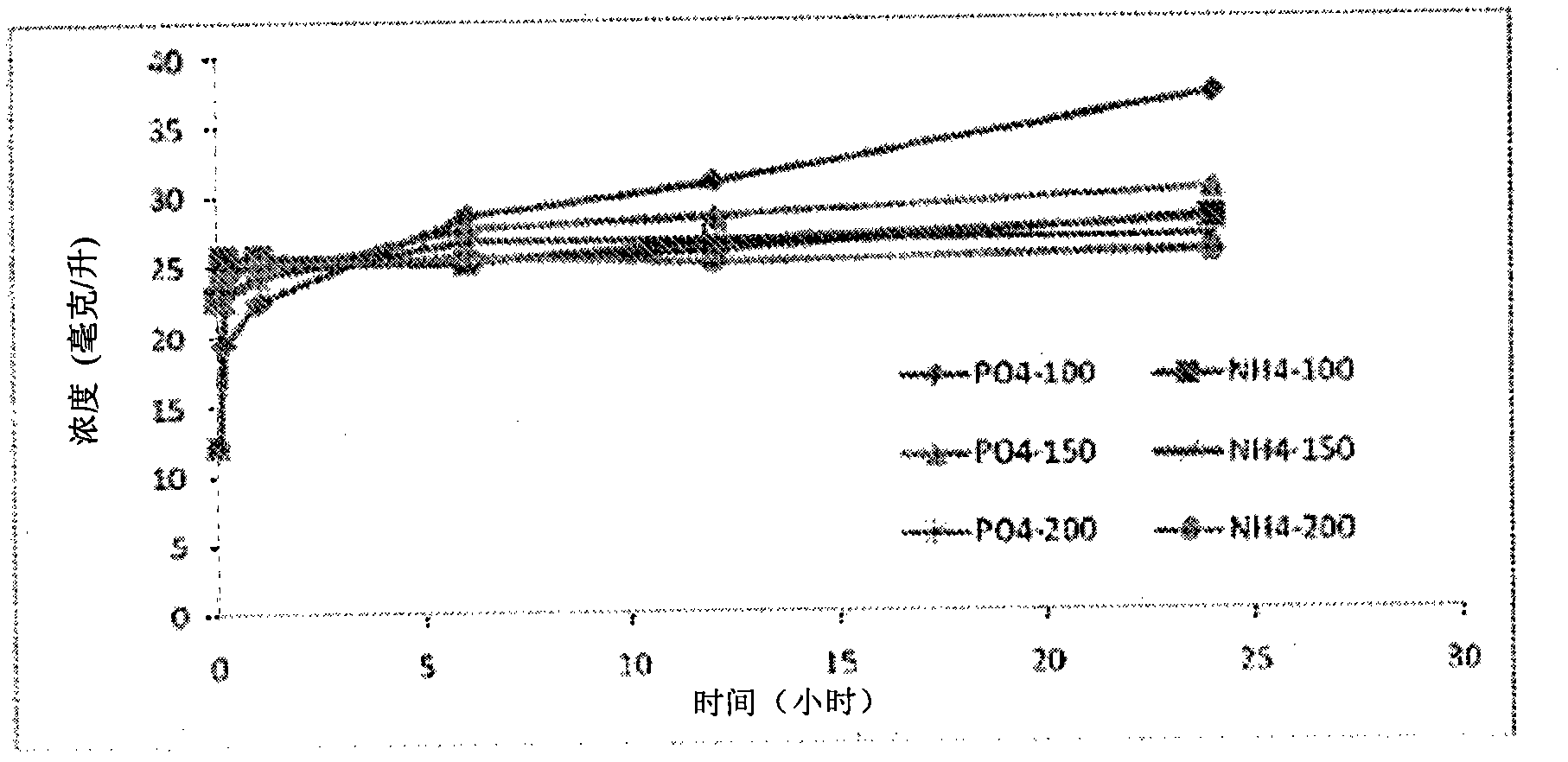

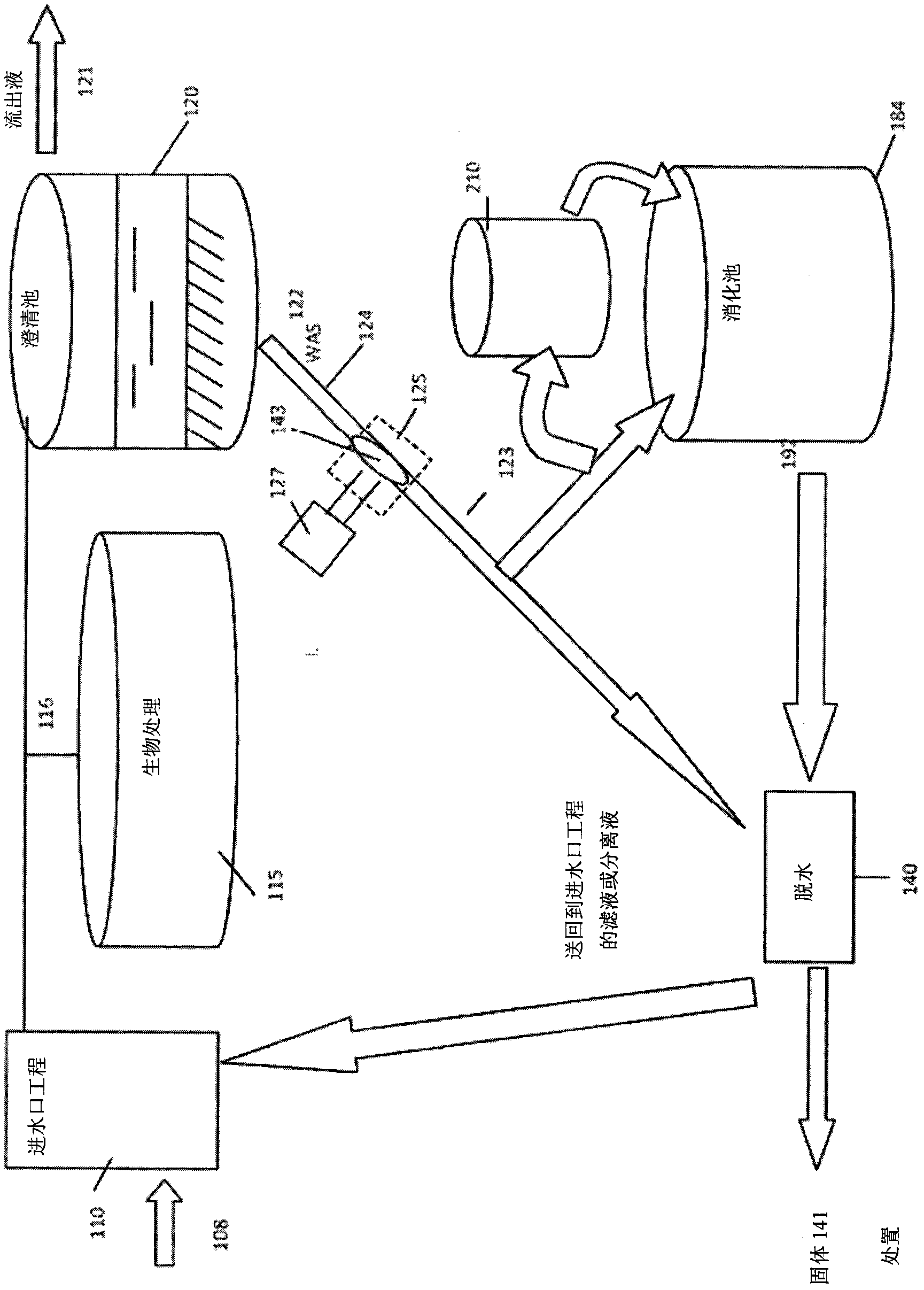

[0064]In a second embodiment of the present invention, waste activated sludge (WAS) can be treated with the same or higher dosage as in the first embodiment and with prolonged contact time to achieve a higher degree of oxidation, cell lysis and The release of intracellular material increases the availability of nutrients and thus significantly increases the activity of microorganisms. In a more specific embodiment, the dosage rate of chlorine dioxide is 50-150 mg / liter, and the sludge is allowed to stand for 24 hours. As the chlorine dioxide oxidizes the materials in the sludge, it is reduced to chlorite. Chlorite is also an oxidizing agent, which is further reduced by contact with organic materials. The resulting sludge contained significantly increased amounts of bioavailable material as bacterial feed, but was not characterized by residual disinfection. This second embodiment is especially important when the subsequent digestion process is anaerobic, since methane product...

example 3

[0073] Treatment of non-digested sludge with chlorine dioxide followed by breeding of the material with appropriate organisms under anoxic conditions can improve biogas production. This approach would have the same advantages when used in conjunction with processes that differentially produce or "harvest" hydrogen prior to methanogenesis in typical anaerobic digestion. An example of such hydrogen production is the use in combination with bioelectrically assisted microbial reactors to produce hydrogen gas. An example of such a reactor is the reactor described in US Patent No. 7,491,453. In another embodiment, the invention is a method of generating hydrogen comprising: obtaining a raw sludge, wastewater sample, or other sample containing biodegradable solids, contacting the sample with chlorine dioxide in an amount sufficient to reduce Or eliminate the microorganisms in the sample and destroy the cell wall of the biosolid material, inoculate the sample treated with chlorine di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com