Artificial cornea porous support material and preparation method thereof

A porous scaffold and artificial cornea technology, applied in medical science, prosthesis, etc., can solve the problems of inability to combine corneal tissue biologically and meet the requirements of artificial cornea porous scaffold materials, and achieve good biocompatibility and high mechanical properties , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

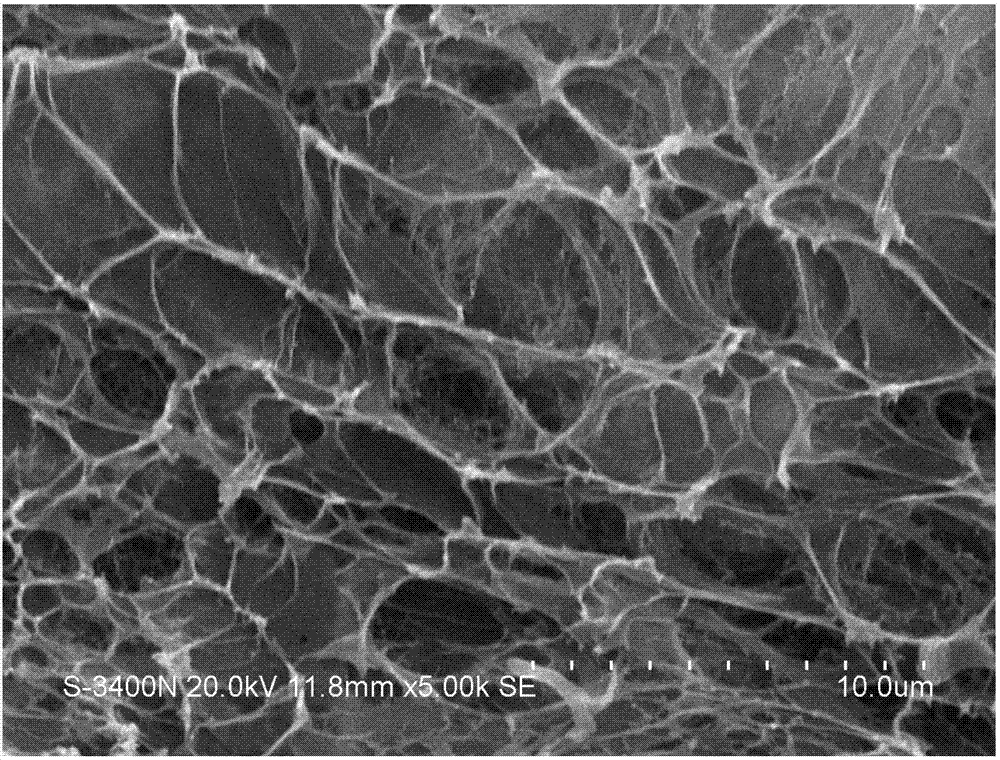

Image

Examples

preparation example Construction

[0015] The present invention also provides a kind of preparation method of artificial cornea porous support material, comprises steps:

[0016] In the first step, polyvinyl alcohol hydrogel is prepared by using polyvinyl alcohol.

[0017] In this step, polyvinyl alcohol can be added into an aqueous solution with a temperature of 85-90°C and a volume percentage of 40%-70% dimethyl sulfoxide and heated at a constant temperature for 2 hours to prepare a polyvinyl alcohol hydrogel.

[0018] In the second step, adding β-tricalcium phosphate and graphite to the polyvinyl alcohol hydrogel to obtain a scaffold material mixture, the weight ratio of the β-tricalcium phosphate to graphite is 1:4 to 4:1, the The weight ratio of β-tricalcium phosphate to polyvinyl alcohol is 1:5 to 2:1, and the weight ratio of graphite to polyvinyl alcohol is 1:5 to 2:1.

[0019] In this step, a porogen can also be added to the polyvinyl alcohol hydrogel, and the porogen is glucose, potassium chloride, so...

Embodiment 1

[0025] A kind of β-tricalcium phosphate / graphite / polyvinyl alcohol composite hydrogel porous scaffold material for artificial cornea, its preparation method comprises the following steps:

[0026] In the first step, 2 g of polyvinyl alcohol is added to an aqueous solution with a temperature of 85 ° C and a volume percentage of 60% dimethyl sulfoxide and heated at a constant temperature for 2 hours to prepare a polyvinyl alcohol hydrogel;

[0027] In the second step, 0.5g of β-tricalcium phosphate, 0.5g of graphite and 5g of glucose were directly added to the polyvinyl alcohol hydrogel and stirred at a constant temperature in a water bath at 90°C for 2 hours to obtain a mixture;

[0028] In the third step, the mixture is directly injected into a sterile mold and subjected to repeated freezing and molding at -40°C to obtain a frozen-molded scaffold material;

[0029] Finally, soak the freeze-formed scaffold material in sterile deionized water and sterilize it with iodine to obta...

Embodiment 2

[0031] A kind of β-tricalcium phosphate / graphite / polyvinyl alcohol composite hydrogel porous scaffold material for artificial cornea, its preparation method comprises the following steps:

[0032] In the first step, 4 g of polyvinyl alcohol is added to an aqueous solution with a temperature of 90 ° C and a volume percentage of 40% dimethyl sulfoxide and heated at a constant temperature for 2 hours to prepare a polyvinyl alcohol hydrogel;

[0033] In the second step, 2 g of β-tricalcium phosphate, 3 g of graphite and 20 g of glucose are directly added to the polyvinyl alcohol hydrogel and stirred at a constant temperature in a water bath at 90° C. for 2 hours to obtain a mixture;

[0034] In the third step, the mixture is directly injected into a sterile mold and subjected to repeated freezing and molding at a temperature of -35° C. to obtain a scaffold material after freezing;

[0035] Finally, soak the freeze-formed scaffold material in sterile deionized water and sterilize i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com