Electrochemical reduction assistance-based biosorption integrated reactor and treatment method of hexavalent chromium-containing wastewater

A technology of biological adsorption and hexavalent chromium, applied in electrochemical water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of long adsorption equilibrium time, slow adsorption rate, and low adsorption efficiency , to achieve the effect of fast speed, simple operation and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

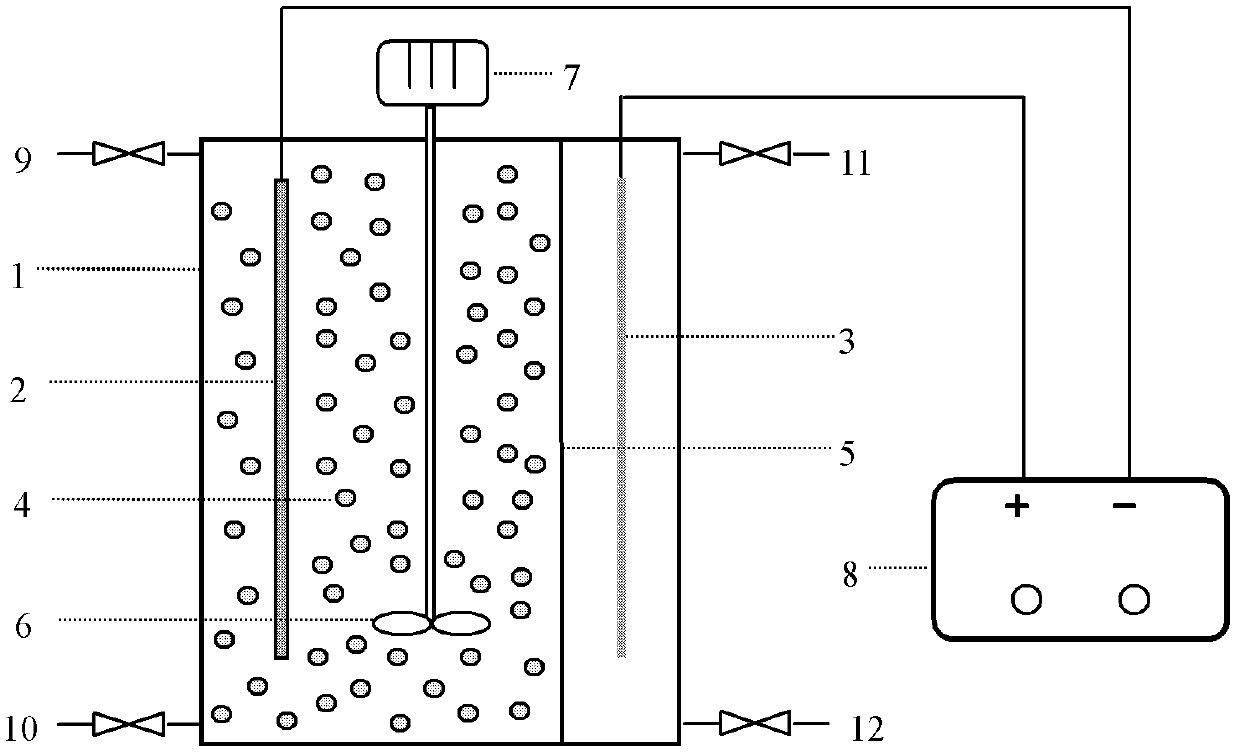

[0034] See figure 1 , an integrated reactor based on electrochemical reduction-assisted biological adsorption treatment of wastewater containing hexavalent chromium, including: cathode 2, anode 3, modified brown algae biosorbent 4, proton exchange membrane 5, stirring paddle 6, stirring motor 7 and DC power supply8.

[0035] A described proton exchange membrane 5 separates the container as the integrated reactor main body 1 into two parts, the cathode chamber and the anode chamber, wherein the cathode chamber is provided with the cathode 2 and the stirring motor 7 connected with the said stirring paddle 6, the said anode 3 is arranged in the anode chamber; connected.

[0036] A water outlet 10 equipped with a valve is provided on the container wall at the bottom of the cathode chamber, and a water inlet 9 equipped with a valve is provided on the container wall at the top of the water outlet, and at the bottom of the anode chamber A water outlet 12 equipped with a valve is a...

Embodiment 2

[0043] The integrated reactor for treating wastewater containing hexavalent chromium based on electrochemical reduction-assisted biosorption of Example 1 was used.

[0044] The modified brown algae biosorbent is modified Sargassum, and the modification method is: dry the Sargassum, grind and sieve, and then sieve the algae with a particle size of 500-800 μm. The grains were immersed in the formaldehyde solution with a mass concentration of 5g / L, the immersion time was 10 hours, and the solid-to-liquid ratio was 15g Sargassum grains / 1L water.

[0045] The surface pretreatment method of the titanium (Ti) plate substrate is the same as that in Example 1, and the pretreated titanium (Ti) plate substrate is immersed in the plating solution of metal gold to carry out the electrodeposition reaction. The preparation of the metal gold plating solution is to dissolve the metered gold soluble precursor compound in the hydrochloric acid solution, and the preparation concentration is 0.5mm...

Embodiment 3

[0049] The integrated reactor for treating wastewater containing hexavalent chromium based on electrochemical reduction-assisted biosorption of Example 1 was used.

[0050] The modified brown algae biosorbent is modified fucales, and the modification method is as follows: drying the fucales, grinding and sieving, and then sieving the obtained particle size to 500-800 μm The algae grains were immersed in the formaldehyde solution with a mass concentration of 1g / L, the immersion time was 40 hours, and the solid-to-liquid ratio was 5g fucus grains / 1L water.

[0051] The surface pretreatment method of the titanium (Ti) plate substrate is the same as in Example 1, and the pretreated titanium (Ti) plate substrate is immersed in the plating solution of ruthenium metal for electrodeposition reaction. The preparation of the plating solution of the ruthenium metal is to dissolve the metered soluble precursor compound of the ruthenium metal in the hydrochloric acid solution, and the prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com