Fluid device for controlling microtubule movement direction, its preparation method and application

A micropipe movement and fluid technology, applied in the manufacture of microstructure devices, microstructure devices, decorative art, etc., can solve the problems of increased research and development costs, high cost, no directionality, etc., to achieve easy control, low cost, and easy movement direction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is used to illustrate the fluid device and its preparation method for controlling the movement direction of microtubules provided by the present invention, and the specific details are as follows:

[0036] (1) Preparation of polydimethylsiloxane (PDMS) stamp:

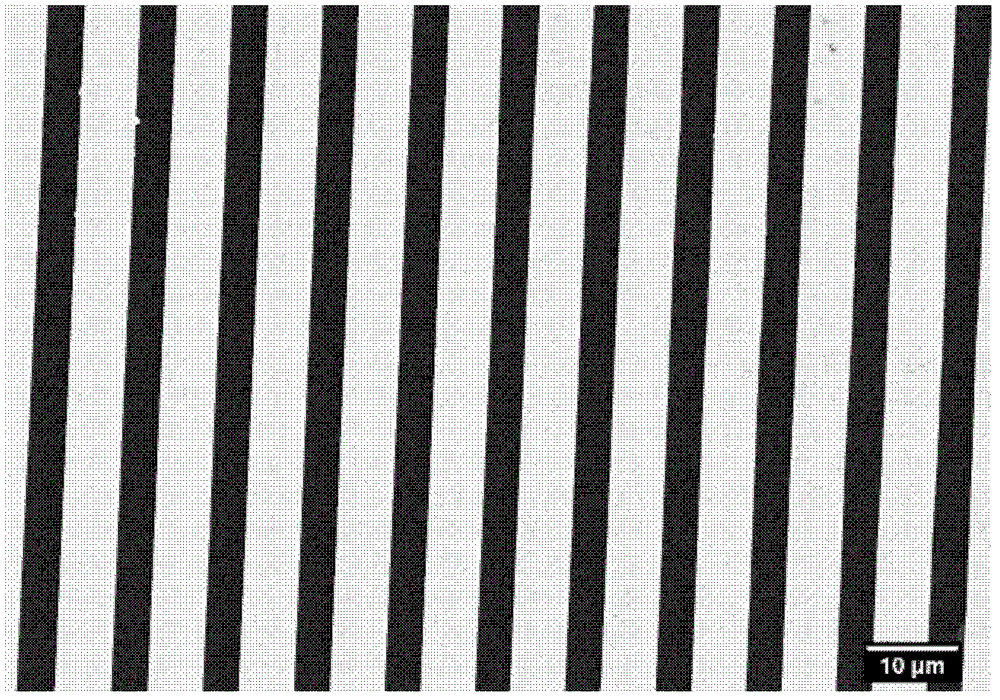

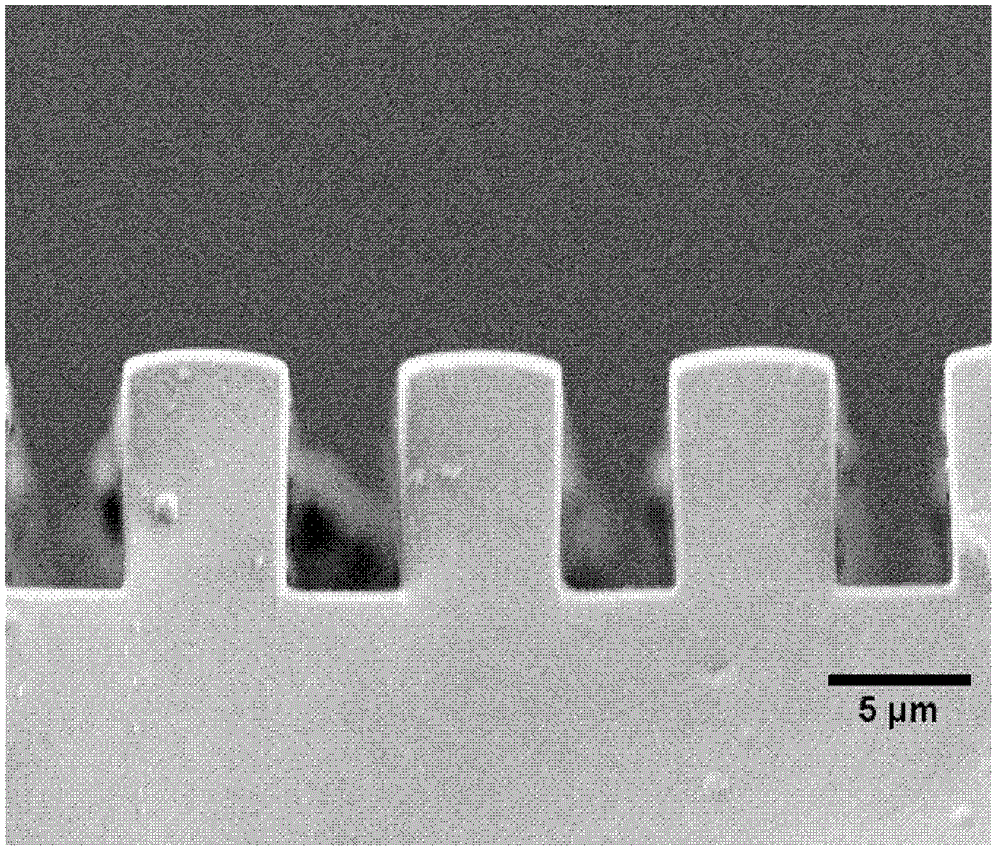

[0037] The silicon template with the micro-nano array in the present invention comes from the Institute of Physics, Chinese Academy of Sciences, and is prepared by a traditional photolithography process. Using the silicon template as a bottom mold, a polydimethylsiloxane stamp was prepared by soft etching. The silicon template has a generally flat surface with a series of parallel grooves that are used to mold the protrusions on the polydimethylsiloxane stamp.

[0038] Silanize and hydrophobicize the silicon template, that is, immerse the silicon template in a toluene solution of 1mM octadecyltrichlorosilane for 2h, rinse with toluene, blow dry with nitrogen, and bake at 120°C for 2h to make the ...

Embodiment 2

[0044] This embodiment is used to illustrate the fluidic device and its preparation method for controlling the movement direction of microtubules provided by the present invention.

[0045] The experimental steps and parameters of this example are basically the same as those in Example 1, the difference is that a casein solution with a concentration of 1 mg / mL is passed into each microfluidic channel for pre-modification, and then a motor with a concentration of 50 nM is passed through. A kinesin solution, the motor kinesin in the motor kinesin solution is prepared by transforming and expressing an exogenous plasmid in Escherichia coli.

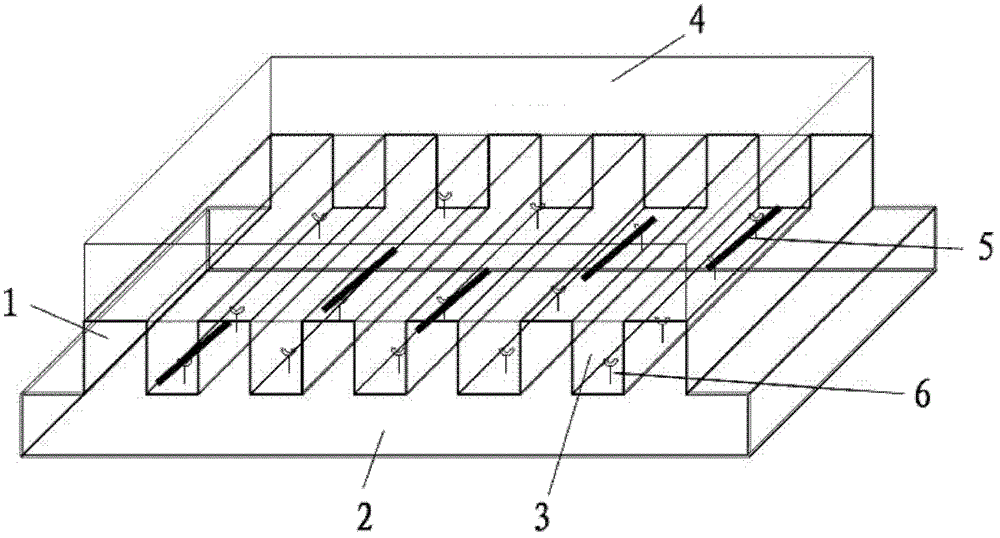

[0046] The fluid device for controlling the movement direction of microtubules prepared by the above steps is as follows: figure 1 shown.

Embodiment 3

[0048] This example is used to illustrate the method of using the fluid device for controlling the direction of movement of microtubules provided by the present invention, or using the fluid device prepared by the preparation method provided by the present invention, for controlling the direction of movement of microtubules. The specific details are as follows :

[0049] (1) Using the preparation method provided in Example 1, a fluidic device for controlling the movement direction of microtubules was prepared.

[0050] (2) Prepare a microtube solution containing oxygen scavenger and ATP. The concentration of the microtube is 4 μg / mL. The oxygen scavenger contains 10 mM glucose, 10 μg / mL glucose oxidase, 4 μg / mL catalase and 0.5 wt% β - Mercaptoethanol, the concentration of ATP is 0.5 mM. In order to make microtubules produce fluorescence for easy observation, microtubules were polymerized by mixing rhodamine-labeled tubulin and unlabeled tubulin at a ratio of 1:4.

[0051] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com