Adhesive used for bonding vulcanized ethylene propylene diene monomer rubber and cast iron, and application thereof

A technology for vulcanizing ternary and ethylene-propylene rubber, applied in the direction of adhesive, adhesive type, bonding method, etc., can solve the problems of complex process and high production cost, and achieve the effect of improving surface energy, increasing surface area and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

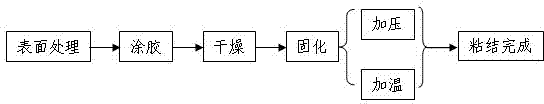

Method used

Image

Examples

Embodiment 1

[0021] Adhesive preparation: The adhesive was prepared by mixing Chemlok-250# 65%, Lekna-1# 30%, and epoxy resin 5% by weight.

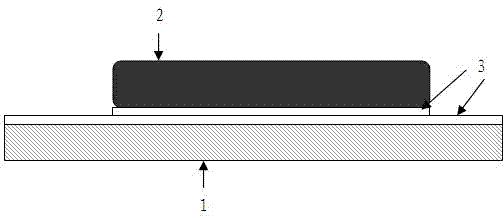

[0022] Surface treatment: mechanical grinding (brushing treatment, grinding with wooden file and sandpaper), vulcanized EPDM rubber 1 (a sample with a length of 155mm, a width of 25mm, and a thickness of 2mm) and cast iron 2 (a sample with a length of 240mm, a width of 30mm, and a thickness of 2mm) sample) and then cleaned with acetone, then soaked vulcanized EPDM rubber in sulfuric acid for 5 minutes, and finally washed with cold water and hot water in turn, and dried (it can be dried naturally). The surface treatment of cast iron adopts mechanical grinding method (that is, sandpaper grinding to remove rust), acetone degreasing, cold water, hot water cleaning and drying, that is, removing sulfuric acid soaking process and other process conditions remain unchanged.

[0023] Glue application: apply adhesive 3 on the bonded surface after surfac...

Embodiment 2

[0026] Adhesive preparation: Prepare the adhesive by mixing 80% of Chemlok-250#, 15% of Lekna-1#, and 5% of epoxy resin by weight.

[0027] Surface treatment: mechanically grind (with wooden files, sandpaper, etc.) the bonding surface of vulcanized EPDM rubber 1 and cast iron 2, then clean it with acetone, then soak the vulcanized EPDM rubber in sulfuric acid for 10 minutes, and finally Wash with cold water, hot water in turn, and dry (just dry naturally). The surface treatment of cast iron adopts mechanical grinding method (that is, sandpaper grinding to remove rust), acetone degreasing, cold water, hot water cleaning and drying, that is, removing sulfuric acid soaking process and other process conditions remain unchanged.

[0028] Glue application: apply adhesive 3 to the bonded surface after surface treatment, and let it dry naturally for 5 minutes.

[0029] Curing: according to figure 2 Bond the bonding surface as shown, and then cure after bonding. The curing ...

Embodiment 3

[0031] Adhesive preparation: Prepare the adhesive by mixing Chemlok-250# 70%, Lekna-1# 25%, and epoxy resin 5% by weight.

[0032] Surface treatment: mechanically grind and vulcanize (with wooden files, sandpaper, etc.) the bonding surface of EPDM rubber 1 and cast iron 2, then clean it with acetone, and then soak the vulcanized EPDM rubber in sulfuric acid for 5 minutes; finally Wash with cold water, hot water in turn, and dry (just dry naturally). The surface treatment of cast iron adopts mechanical grinding method (that is, sandpaper grinding to remove rust), acetone degreasing, cold water, hot water cleaning and drying, that is, removing sulfuric acid soaking process and other process conditions remain unchanged.

[0033] Glue application: apply adhesive 3 on the bonded surface after surface treatment, and let it dry naturally for 3 minutes.

[0034] Curing: according to figure 2 Bond the bonding surface as shown, and then cure after bonding. The curing pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com