Method for leaching bastnaesite-containing rare-earth ore concentrates in complexing mode and preparing kryocide

A rare earth concentrate, cryolite technology, applied in aluminum fluoride, process efficiency improvement, aluminum halide and other directions, can solve the problem of unable to solve the problem of fluorine recycling, large fluorine-containing waste water, pollution of the environment and other problems, achieve good Economic and environmental benefits, low equipment requirements, and good quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

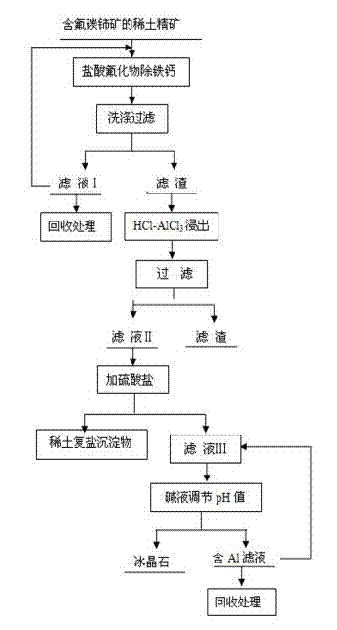

[0030] Such as figure 1 As shown, 2 kg of Sichuan Mianning bastnaesite was weighed, and the rare earth oxide content was 61.5%. In a closed device with a condensing system, add 3mol / L hydrochloric acid at a liquid-solid ratio of 8:1, add 5ml of analytically pure hydrofluoric acid, heat to 95°C, add the above concentrate, stir at a constant speed for 2 hours, and react After finishing, cool to 55°C, filter and wash to obtain filtrate I and filter residue. The filtrate I is recycled.

[0031] Add HCl solution and AlCl to the filter residue 3 Solid, complex leaching according to the following conditions: In a closed device with a condensation system, the concentration of HCl is 6mol / L, AlCl 3 The concentration is 2mol / L, the leaching temperature is 110°C, and the liquid-solid ratio is 30:1. After stirring at a constant speed for 90 minutes, cool to 85°C and heat filter, and wash the filter residue with 85°C distilled water for 3 times to obtain filtrate II.

[0032] Will K 2...

Embodiment 2

[0035] Such as figure 1As shown, 2 kg of Sichuan Mianning bastnaesite was weighed, and the rare earth oxide content was 61.5%. In a closed device with a condensing system, add 3mol / L hydrochloric acid at a liquid-solid ratio of 8:1, add 7g of sodium fluoride solid, heat to 95°C, add the above concentrate, stir at a constant speed for 2 hours, and the reaction is over After cooling to 55°C, filtering and washing, the filtrate I and filter residue were obtained. The filtrate I is recycled.

[0036] Add HCl solution and AlCl to the filter residue 3 Solid, complex leaching according to the following conditions: In a closed device with a condensation system, the concentration of HCl is 6mol / L, AlCl 3 The concentration was 2mol / L, the leaching temperature was 110°C, the liquid-solid ratio was 30:1, stirred at a constant speed for 90 minutes, then cooled to 85°C for hot filtration, and the filter residue was washed 3 times with 85°C distilled water to obtain filtrate II.

[0037]...

Embodiment 3

[0040] Such as figure 1 As shown, 2kg of Baotou mixed rare earth concentrate was weighed, and the content of bastnaesite was 41.06%. In a closed device with a condensation system, add 3mol / L hydrochloric acid at a liquid-solid ratio of 8:1, add 6g of calcium fluoride solid, heat to 95°C, add the above concentrate, stir at a constant speed for 2 hours, and the reaction is over After cooling to 55°C, filtering and washing, the filtrate I and filter residue were obtained. The filtrate I is recycled.

[0041] Add HCl solution and AlCl to the filter residue 3 Solid, complex leaching according to the following conditions: In a closed device with a condensation system, the concentration of HCl is 6mol / L, AlCl 3 The concentration is 2mol / L, the leaching temperature is 110°C, and the liquid-solid ratio is 30:1. After stirring at a constant speed for 90 minutes, cool to 85°C and heat filter, and wash the filter residue with 85°C distilled water for 3 times to obtain filtrate II.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com