Dual-wavelength differential temperature measuring system based on optical-fiber radiation attenuation temperature dependency

A technology of temperature dependence and temperature measurement, applied in thermometers, measuring devices, measuring heat, etc., can solve the problems of small temperature variation in F-P cavity length, complicated F-P manufacturing process, and limited sensing temperature range, etc., to achieve suppression of optical fiber bending, Low cost, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

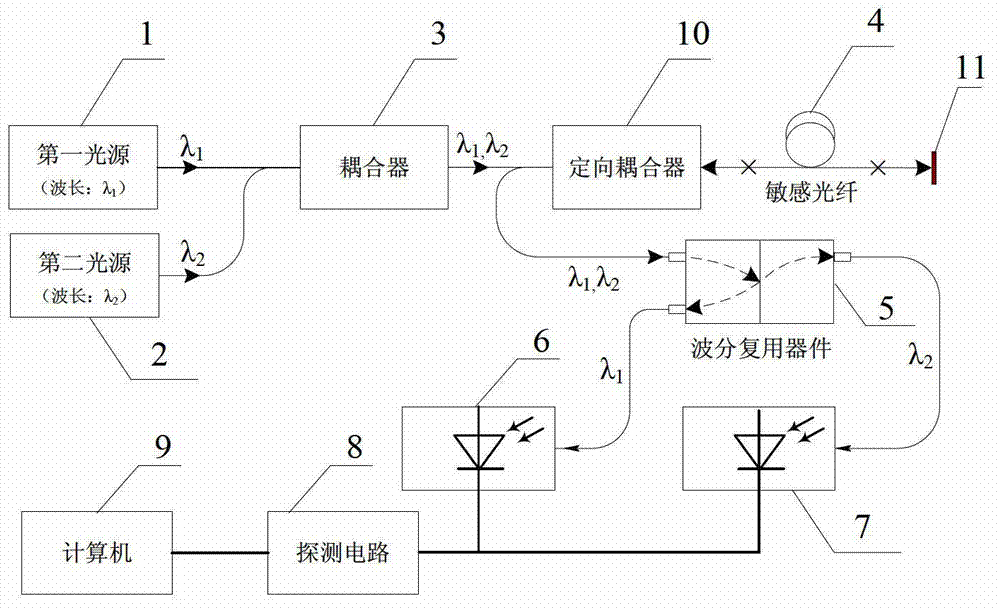

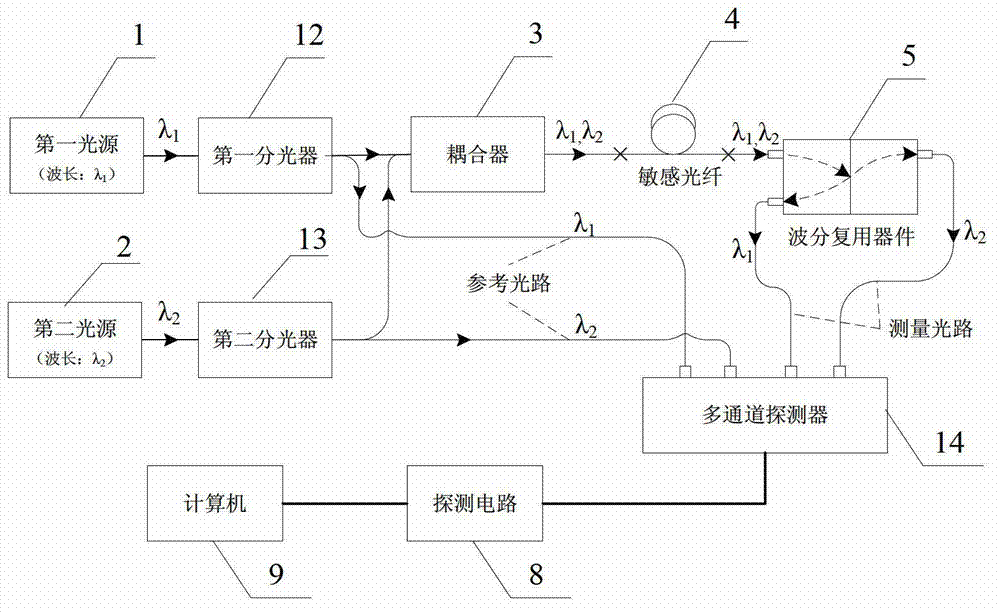

[0030] The invention is a dual-wavelength differential temperature measurement system based on the temperature dependence of optical fiber radiation-induced attenuation, and has three schemes.

[0031] The first option:

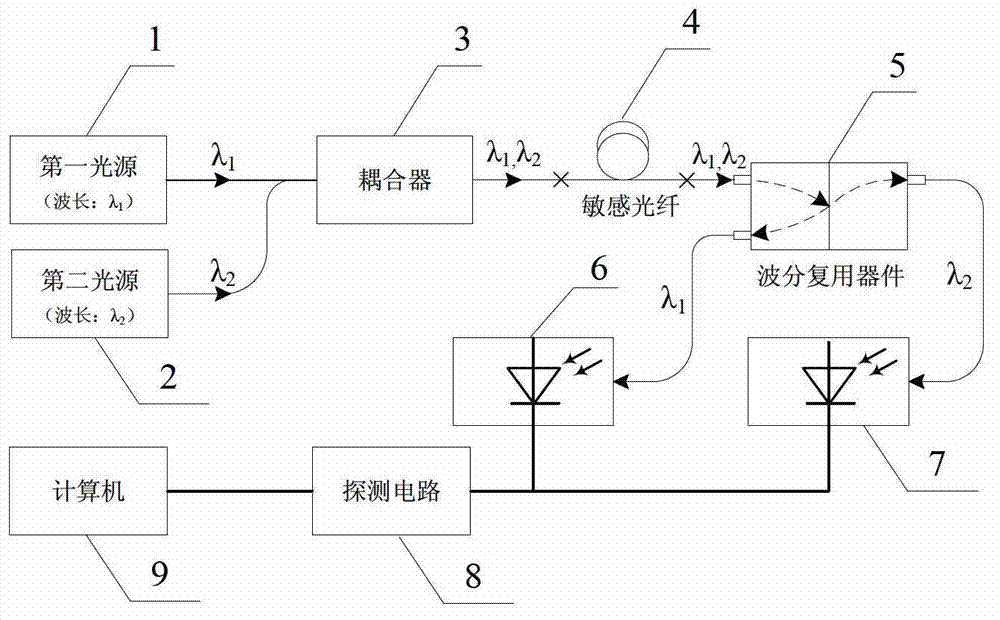

[0032] The first option, such as figure 1 As shown, it includes a first light source 1 and a second light source 2 for providing two different wavelength bands of light waves, a coupler 3 for coupling light, a sensitive optical fiber 4 for sensitive temperature changes, and a waveband for separating two wavelengths of light. A demultiplexing device 5, a first detector 6 and a second detector 7 for detecting two-way optical signals, a detection circuit 8 for processing the detected optical signals, and a computer 9 for signal processing and display.

[0033] The first light source 1 emits λ 1 wavelength band, the second light sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com