Preparation method of lithium ion battery gel electrolyte and lithium ion battery containing gel electrolyte

A gel electrolyte and lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve problems such as poor electrochemical performance and poor safety performance, and achieve the effects of low cost, simple process, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

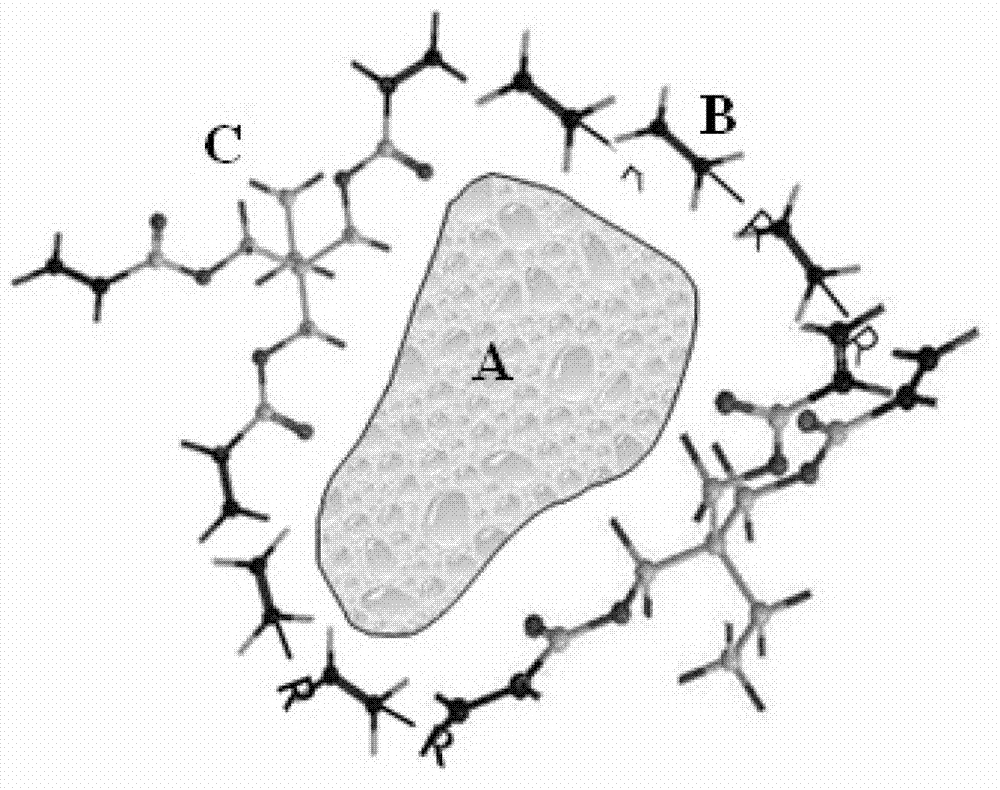

Image

Examples

Embodiment 1

[0053] Preparation of gel electrolyte: Weigh the following components according to the following mass relationship for use: E1: PVDF: methyl methacrylate: trimethylolpropane triacrylate: dibenzoyl peroxide is 99.979:0.05:0.05:0.1 : 0.001; Add the weighed PVDF into the weighed E1, fully stir until it is evenly dispersed in E1, then add the weighed methyl methacrylate and trimethylolpropane triacrylate, fully Stir to obtain a prepolymer gel electrolyte, and finally, add a weighed initiator dibenzoyl peroxide within one month before use, and stir thoroughly to obtain a ready-to-use gel electrolyte.

[0054] Preparation of battery cell to be filled with liquid: same as Comparative Example 1.

[0055] Injection and cell molding: inject the above-mentioned gel electrolyte into the battery cell after Baking, then seal it, and let it stand until the electrolyte fully infiltrates the entire diaphragm; then apply a pressure of 10MPa on the surface of the cell, and place the cell at 150 ...

Embodiment 2

[0057] Preparation of gel electrolyte: Weigh the following components according to the following mass relationship: E1: SBR: ethyl acrylate: propoxylated trimethylolpropane triacrylate: peroxydicarbonate is 74.95:10:10: 0.05:5; Add the weighed SBR into the weighed E1, stir well until it is evenly dispersed in E1, then add the weighed ethyl acrylate and propoxylated trimethylolpropane triacrylic acid ester, fully stirred to obtain a pre-polymer gel electrolyte, and finally, a weighed initiator peroxydicarbonate was added within one month before use, and fully stirred to obtain a ready-to-use gel electrolyte.

[0058] Preparation of battery cell to be filled with liquid: same as Comparative Example 1.

[0059] Injection and cell molding: inject the above-mentioned gel electrolyte into the battery cell after Baking, then seal it, and let it stand until the electrolyte fully infiltrates the entire diaphragm; then apply a pressure of 0.001MPa on the surface of the cell, and place t...

Embodiment 3

[0061] Preparation of gel electrolyte: Weigh the following components according to the following mass relationship for use: E1: PVDF: lauryl acrylate: ethoxylated trimethylolpropane triacrylate: dibenzoyl peroxide is 94.8:2: 2:1:0.2; Add the weighed PVDF into the weighed E1, stir well until it is evenly dispersed in E1, then add the weighed lauryl acrylate and ethoxylated trimethylol Propane triacrylate, fully stirred to obtain a prepolymer gel electrolyte, and finally, a weighed initiator dibenzoyl peroxide was added within two days before use, and fully stirred to obtain a ready-to-use gel electrolyte.

[0062] Preparation of battery cell to be filled with liquid: same as Comparative Example 1.

[0063] Injection and cell molding: inject the above-mentioned gel electrolyte into the battery cell after Baking, then seal it and let it stand until the electrolyte fully infiltrates the entire diaphragm; then apply a pressure of 0.6 MPa on the surface of the cell, and place the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com