Orodispersible tablets of erythritol and isomalt

A technology of isomalt and erythritol, which is applied in the directions of pill delivery, medical preparations of non-active ingredients, and pharmaceutical formulations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The crude erythritol product (Cargill Zerose® 16957) was ground in a Bauermeister turbine mill UTL with a 1 mm sieve to obtain a powder with a volume mean diameter of 25 μm. The volume mean diameter is measured by laser diffraction.

[0071] 400 g of ground erythritol powder was mixed with 100 g of isomalt (Cargill C*lsoMaltidex ?) for 10 seconds of dry mixing.

[0072] Add 30ml of water dropwise at a rate of 5ml / min. After the liquid was added, the blend was continued to mix for 60 seconds.

[0073] The granulated powder was hand wet sieved with a 2 mm sieve.

[0074] The wet sieved granules were dried in a fluidized bed (Aeromatic-Fielder GEA-Strea-1) at a temperature of 60° C. for 30 minutes.

[0075] The dried granules were sieved through a 0.315 mm sieve for 5-10 minutes in a granulator (Erweka (FGS+AR400E)) at 100 rpm.

example 2A

[0076] Example 2A - Comparative Example

[0077] The granulated product obtained from Example 1 was then mixed with 1% magnesium stearate in a Pharmatech apparatus at a speed of 28 rpm.

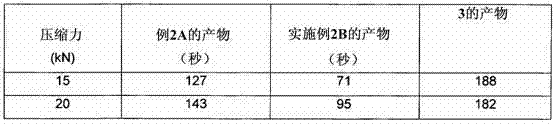

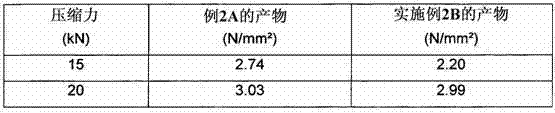

[0078] The granulated product was compressed in a tablet press (Korsch-PH100) with a compression force varying from 5 kN to 20 kN.

[0079] Tablets have a 1cm 2 The surface of the tablet has a diameter of 11.3mm and its weight is 350mg.

Embodiment 2B

[0081] The granulated product obtained from Example 1 was then (dry) blended in a Pharmatech apparatus at 28 rpm with 2% Ac-di-sol (disintegrant) and 1% magnesium stearate.

[0082] The granulated product was compressed in a tablet press (Korsch-PH100) with a compression force varying from 5 kN to 20 kN.

[0083] Tablets have a 1cm 2 The surface of the tablet has a diameter of 11.3mm and its weight is 350mg.

[0084] Example 3 - Comparative example - according to WO2010 / 025796

[0085]The crude erythritol product (Cargill C*PharmEridex 16956) was ground in a Bauermeister turbine mill UTL with a 1 mm sieve to obtain a powder with a volume mean diameter of 30 μm.

[0086] The volume mean diameter is measured by laser diffraction. Erythritol has 0.40m 2 / g specific surface area.

[0087] 500 g of ground erythritol powder were dry blended for 60 seconds in a high shear mixer (Pro-C-ept-Mi-Pro, chopper: 3000 rpm, and impeller: 1200 rpm).

[0088] 79.17 g of liquid sorbitol (7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com