Honey pomelo soft sweets and preparation method thereof

A production method and technology of honey pomelo, applied in confectionery, confectionery industry, food science and other directions, can solve the problems of honey pomelo color, loss of natural flavor and nutrients, short debittering and boiling time, affecting production efficiency, etc. Good color, good taste, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Clean the raw material honey pomelo with 100ppm of chlorine dioxide, wash the soil, remove pests, scars, damage, rot and other unqualified peels to obtain peel and pulp;

[0028] (2) Crushing the pulp and filtering it with a 100-mesh filter, and taking the filtrate to obtain the pomelo juice;

[0029] (3) Evenly mix the pomelo juice and the ion exchange resin used for beverages in a mass ratio of 7:1, and let it stand for 6 minutes, then centrifuge the pomelo juice and the ion exchange resin to complete debittering, After bitterness, go through colloid mill and sterilization to get the original juice of debitter pomelo;

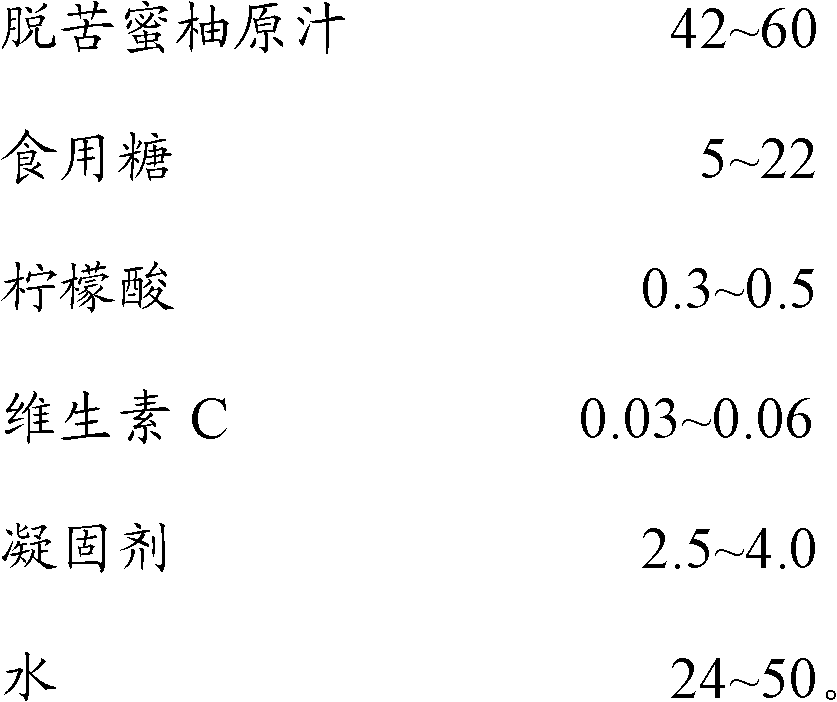

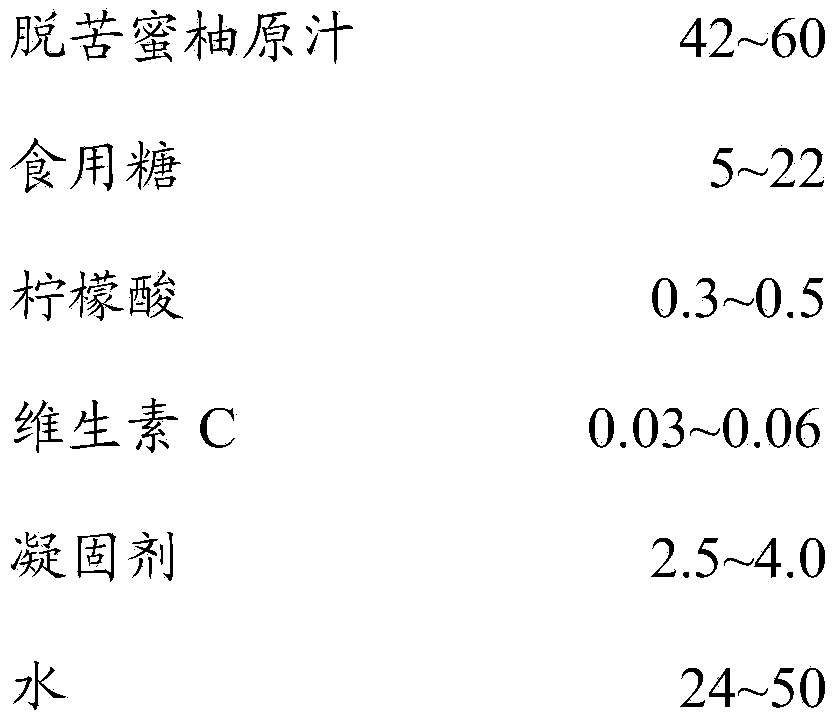

[0030] (4) The sugar solution is configured in the following parts by weight, including 45 parts by weight of the debittered pomelo juice, 8 parts by weight of maltose, 7 parts by weight of white granulated sugar, 0.45 parts by weight of citric acid, 0.05 parts by weight of vitamin C, and 3.2 parts by weight of carrageenan. Parts by weight, 36.3 p...

Embodiment 2

[0035] Its processing steps (1), (2) and (6) are identical with embodiment 1.

[0036] The processing conditions of all the other steps are as follows:

[0037] (3) Evenly mix the pomelo juice and the ion exchange resin used for beverages in a mass ratio of 6:1, and let it stand for 4 minutes, then centrifuge the pomelo juice and the ion exchange resin to complete debittering, After bitterness, go through colloid mill and sterilization to get the original juice of debitter pomelo;

[0038] (4) Configure the sugar solution in the following parts by weight, including 50 parts by weight of the debittered pomelo juice, 7 parts by weight of white granulated sugar, 7 parts by weight of maltose, 8 parts by weight of honey, 0.4 parts by weight of citric acid, and 0.05 parts by weight of vitamin C Part, 3.5 parts by weight of carrageenan, 24.05 parts by weight of water;

[0039] (5) After the sugar solution is passed through a colloid mill, it is heated to 100° C. and then vacuum-boi...

Embodiment 3

[0042] Its processing steps (1), (2) and (6) are identical with embodiment 1.

[0043] The processing conditions of all the other steps are as follows:

[0044] (3) Evenly mix the pomelo juice and the ion exchange resin used for beverages in a mass ratio of 8:1, and let it stand for 9 minutes, then centrifuge the pomelo juice and the ion exchange resin to complete debittering, After bitterness, go through colloid mill and sterilization to get the original juice of debitter pomelo;

[0045] (4) Configure the sugar solution in the following parts by weight, including 60 parts by weight of the debittered pomelo juice, 5 parts by weight of preserved fruit syrup, 0.3 parts by weight of citric acid, 0.03 parts by weight of vitamin C, 2.5 parts by weight of carrageenan, and 32.17 parts by weight of water. parts by weight;

[0046] (5) After the sugar solution is passed through a colloid mill, it is heated to 100° C. and then vacuum-boiled. The time for vacuum cooking is 80 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com