Bio-based water-soluble polymer solution, and preparation method and application thereof

A water-soluble polymer, bio-based technology, applied in the preparation of animal glue or gelatin, adhesive types, protein adhesives, etc., can solve the problems of poor water resistance, curing agent derived from petrochemical resources, etc. Good performance, low production cost, and the effect of reducing use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

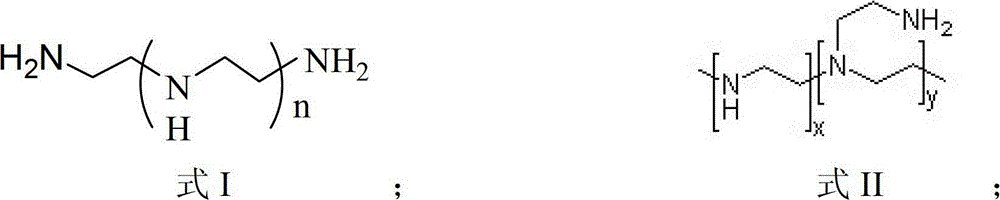

[0043] 1) Add 30g of water and 37.8g of tetraethylenepentamine (formula I structure, n=3, chemically pure, purchased from Sinopharm Chemical Reagent Co., Ltd.) into a 500mL three-necked bottle, and then add 29.2g of adipic acid (chemically pure , purchased from Sinopharm Group Chemical Reagent Co., Ltd.) to obtain a mixed solution, put the mixed solution in an oil bath at 190°C, react in the open for 40 minutes, stop the reaction, add 450g of water, stir evenly, and obtain an aqueous solution of polycondensation polymer;

[0044] 2) Add 18.6g of epichlorohydrin to the aqueous solution of polycondensation polymer obtained in step 1), react in an oil bath at 65°C for 100 minutes, and discharge to obtain a bio-based water-soluble polymer solution, that is, a kind of adipic acid-based Water-soluble polymer solution with a solid content of 15.1%;

[0045] 3) Add 30g of the bio-based water-soluble polymer solution obtained in step 2) into a 500mL three-necked bottle, then add 100g o...

Embodiment 2

[0048] 1) Add 20g of water and 31g of diethylenetriamine (formula I structure, n=1, chemically pure, purchased from Sinopharm Chemical Reagent Co., Ltd.) into a 500mL three-necked bottle, and then add 39g of itaconic acid (chemically pure, purchased from (Sinopharm Group Chemical Reagent Co., Ltd.) to obtain the mixed solution, put the mixed solution in an oil bath at 160°C, react in the open for 60 minutes, stop the reaction, add 100g of water, stir evenly, and obtain an aqueous solution of polycondensation polymer;

[0049] 2) Add 27.8g of epichlorohydrin to the aqueous polycondensation polymer solution obtained in step 1), react in an oil bath at 70°C for 10 minutes, and discharge to obtain a bio-based water-soluble polymer solution, that is, an itaconic acid-based Water-soluble polymer solution with a solid content of 47.9%;

[0050] 3) Add 15g of the bio-based water-soluble polymer solution obtained in step 2) into a 500mL three-neck bottle, then add 100g of water and 40g...

Embodiment 3

[0053] 1) Add 40g of water and 43.5g of polyethylene polyamine (formula II structure, chemically pure, purchased from Sinopharm Chemical Reagent Co., Ltd., molecular weight 232.38, -NH 2 Functionality is calculated as 4), then add 70.3g of succinic acid (chemically pure, purchased from Sinopharm Chemical Reagent Co., Ltd.) to obtain a mixed solution, put the mixed solution in an oil bath at 190°C, react in the open for 70min, and stop the reaction , add 180g water, stir evenly, obtain the aqueous solution of polycondensation polymer;

[0054] 2) Add 58g of epichlorohydrin to the aqueous polycondensation polymer solution obtained in step 1), react in an oil bath at 70°C for 50 minutes, and discharge to obtain a bio-based water-soluble polymer solution, that is, a succinic acid-based Water-soluble polymer solution, solid content 47.3%;

[0055] 3) Add 13g of the bio-based water-soluble polymer solution obtained in step 2) into a 500mL three-necked bottle, then add 100g of water a...

PUM

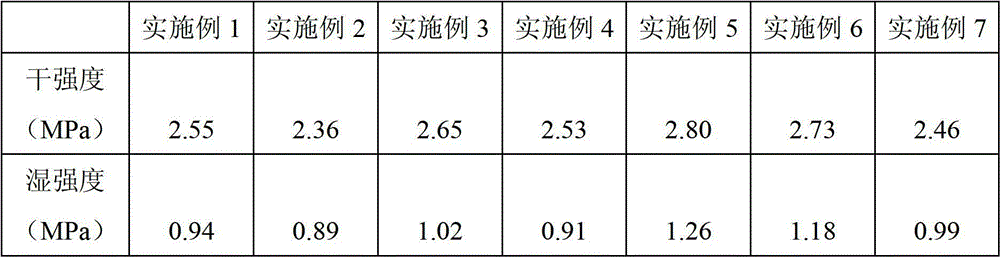

| Property | Measurement | Unit |

|---|---|---|

| Dry strength | aaaaa | aaaaa |

| Dry strength | aaaaa | aaaaa |

| Dry strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com