Preparation method of HPEI (hyperbranched polyethyleneimine)-encapsulated iron oxide magnetic nano particles

A magnetic nanoparticle and nanoparticle technology, applied in the fields of magnetic properties of inorganic materials, preparations for in vivo tests, and pharmaceutical formulations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

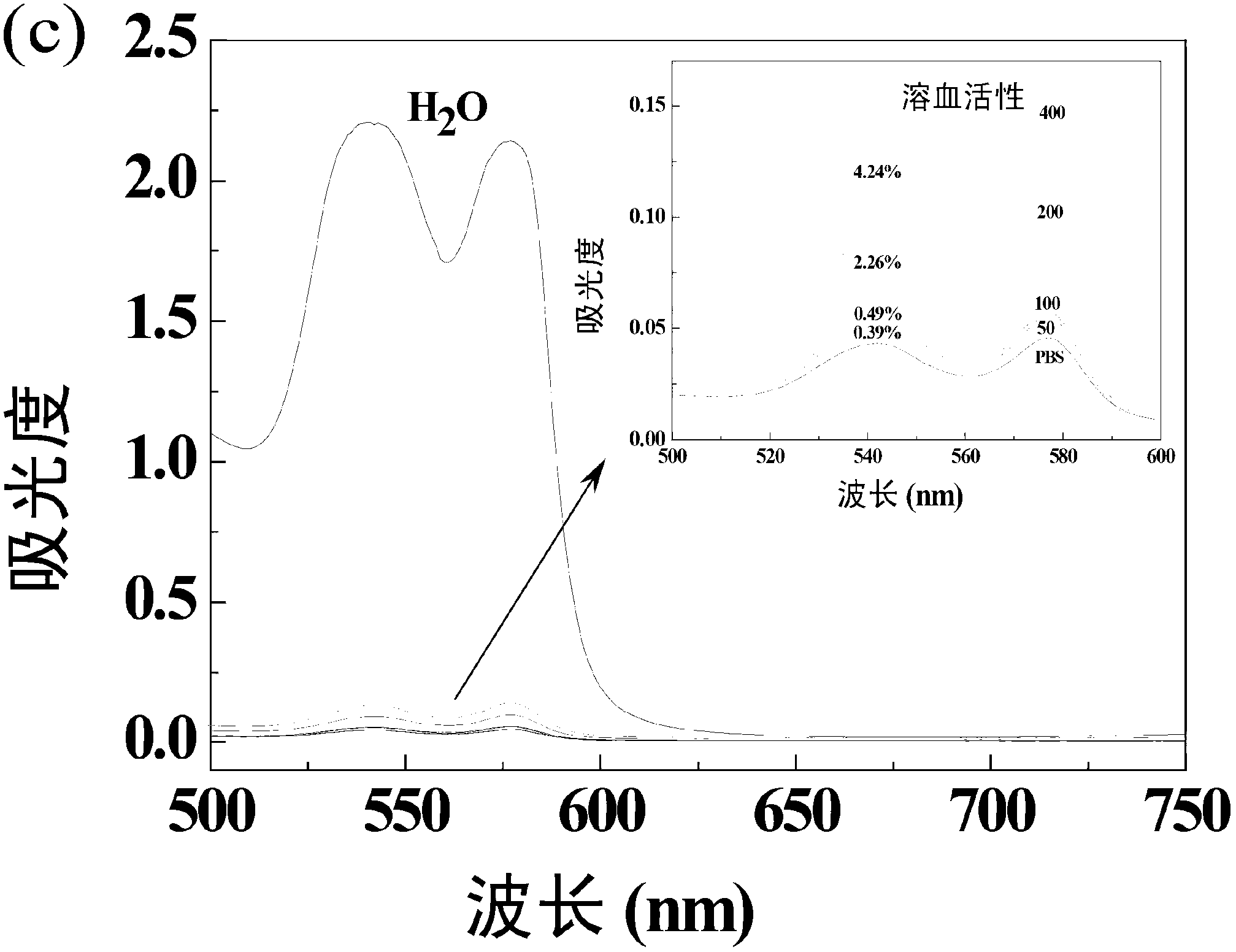

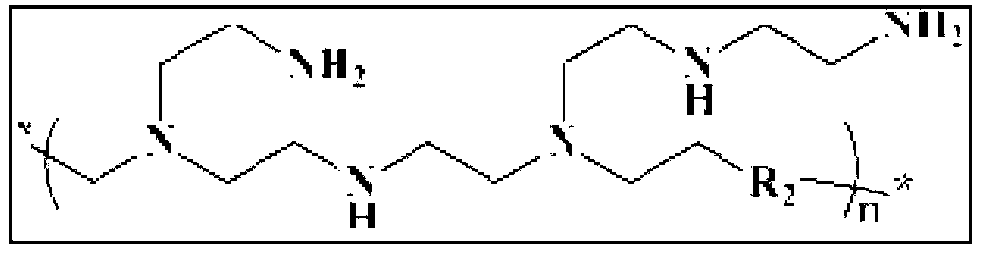

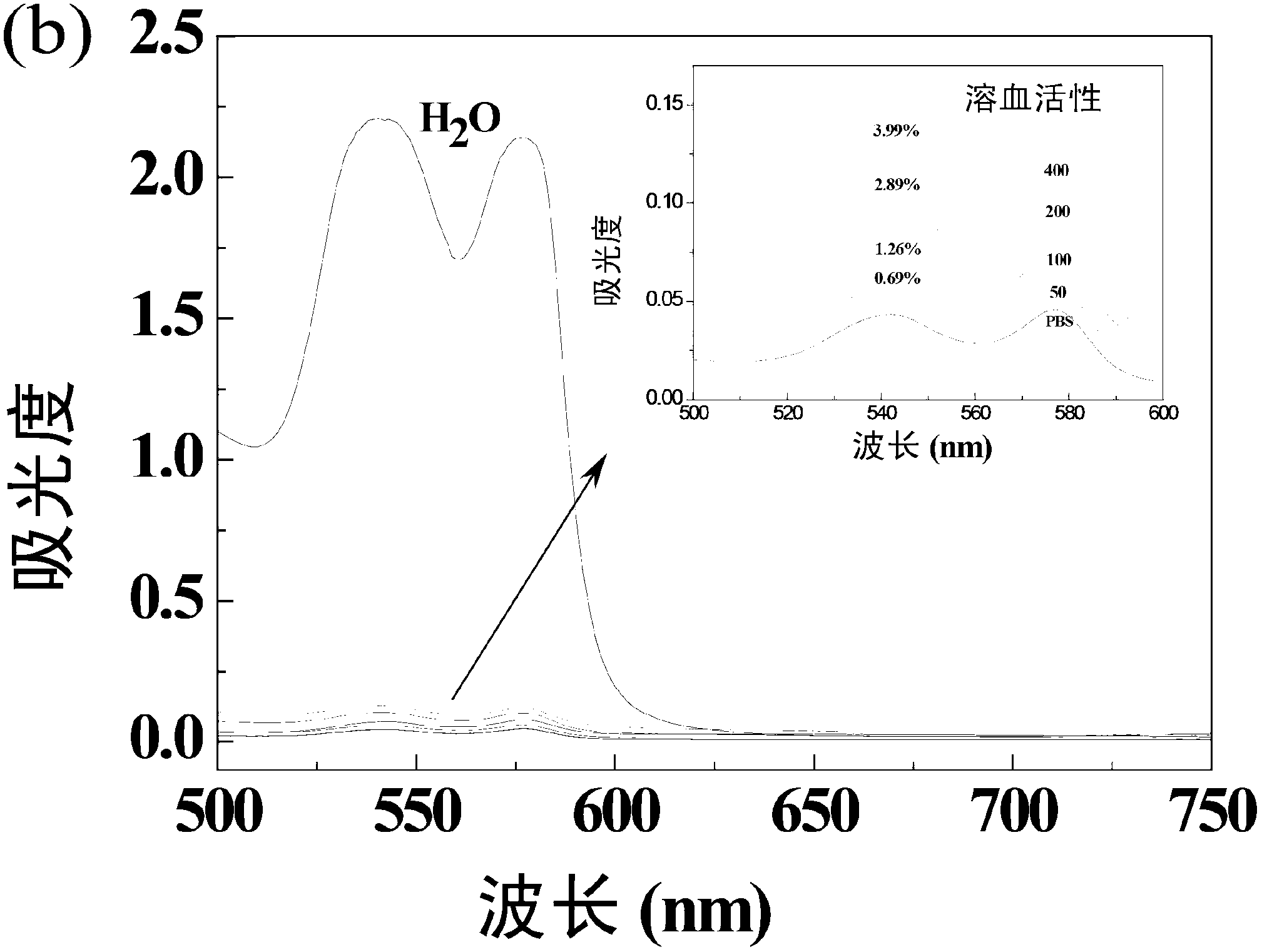

Embodiment 1

[0065] 1.2519g FeCl 2 4H 2 O was added to the beaker, 7.75mL of ultrapure water (resistivity greater than 18.2MΩ.cm) was added, and 6.25mL of NH 3 ·H 2 O, the above-mentioned mixed solution was continuously stirred in the air for 10 minutes to ensure that the ferrous iron was fully oxidized, and then the reactant was transferred to the reaction kettle. Dissolve 0.53879g HPEI in 5mL aqueous solution, ultrasonically dissolve it, transfer it to the reaction kettle with a pipette gun, mix well with the solution in the reaction kettle, and react at 134~140℃ for about 3 hours; after the reaction, the natural After cooling to room temperature, the resulting black precipitated Fe 3 o 4 / HPEI is dispersed in ultrapure water, magnetically separated, redispersed, and magnetically separated, and washed with pure water five times to remove excess reagents, and redispersed in the water phase to obtain polyethyleneimine-protected tetraoxide Tri-iron nanoparticles (No.1 Fe 3 o 4 / HPEI);...

Embodiment 2

[0068] (1) Add 0.252g FeCl 2 4H 2 Add O into the beaker, then add 12.75mL of ultrapure water (resistivity greater than 18.2MΩ.cm), and add 1.25mL of NH 3 ·H 2 O, the above-mentioned mixed solution was continuously stirred in the air for 10 minutes to ensure that the ferrous iron was fully oxidized, and then the reactant was transferred to the reaction kettle. Dissolve 0.05153g HPEI in 5mL aqueous solution, ultrasonically dissolve it, transfer it to the reaction kettle with a pipette gun, mix well with the solution in the reaction kettle, and react at 134~140℃ for about 3 hours; refer to Table 1; After finishing, naturally cool to room temperature, the black precipitated Fe that obtains 3 o 4 / HPEI is dispersed in ultrapure water, magnetically separated, redispersed, and magnetically separated, and washed with pure water five times to remove excess reagents and redispersed in the water phase. The polyethyleneimine-wrapped ferric oxide nanoparticles No. 2 Fe 3 o 4 / HPEI; ...

Embodiment 3

[0071] (1) Add 0.25294g FeCl 2 4H 2 Add O into the beaker, add 12.75mL of ultrapure water (resistivity greater than 18.2MΩ.cm), and add 1.25mL of NH 3 ·H 2 O, the above-mentioned mixed solution was continuously stirred in the air for 10 minutes to ensure that the ferrous iron was fully oxidized, and then the reactant was transferred to the reaction kettle. Dissolve 0.1037g of HPEI in 5mL of aqueous solution, ultrasonically dissolve it, transfer it into the reactor with a pipette gun, mix well with the solution in the reactor, and react at 134~140°C for about 3 hours; refer to Table 1;

[0072] (2) After the reaction, cool down to room temperature naturally, and remove the obtained black precipitate Fe 3 o 4 / HPEI is dispersed in ultrapure water, magnetically separated, redispersed, and magnetically separated, and washed with pure water five times to remove excess reagents and redispersed in the water phase. The polyethyleneimine-wrapped ferric iron oxide nanoparticles No....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com