Cabo wood-plastic composite and preparation process thereof

A wood-plastic composite material and tobacco stem technology, which is applied in the field of wood-plastic composite materials and their preparation, can solve the problems of unutilized and unseen plant fibers, and can increase water vapor barrier properties and ray barrier properties, and enhance water resistance. and UV resistance, the effect of improving material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、 Embodiment 2、 Embodiment 3

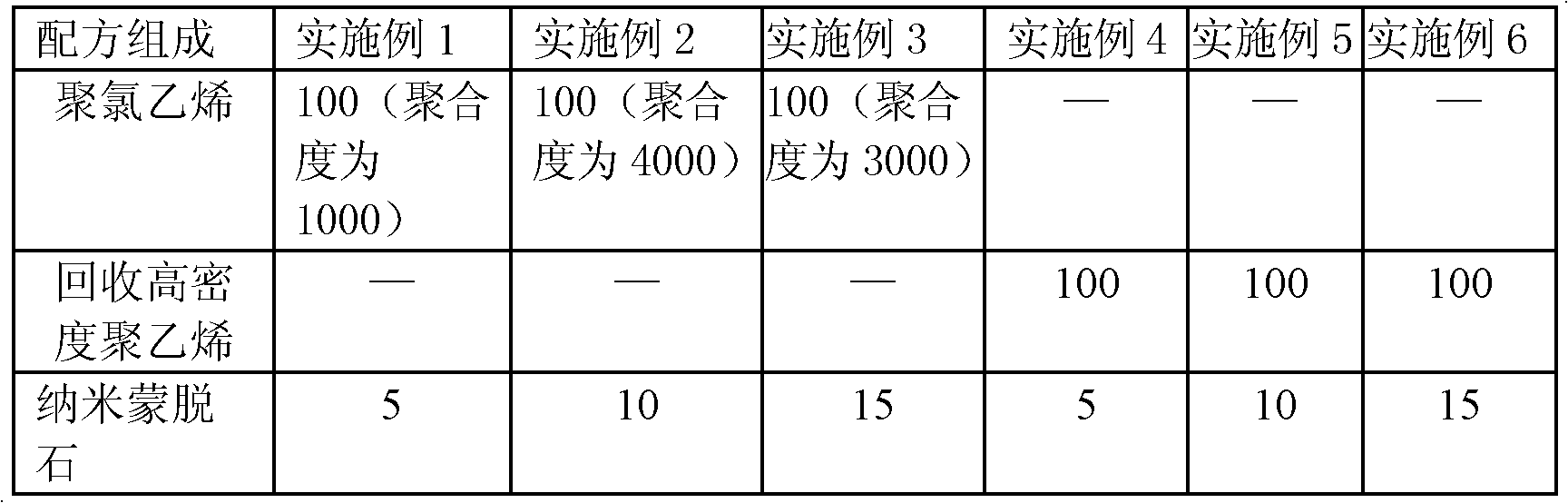

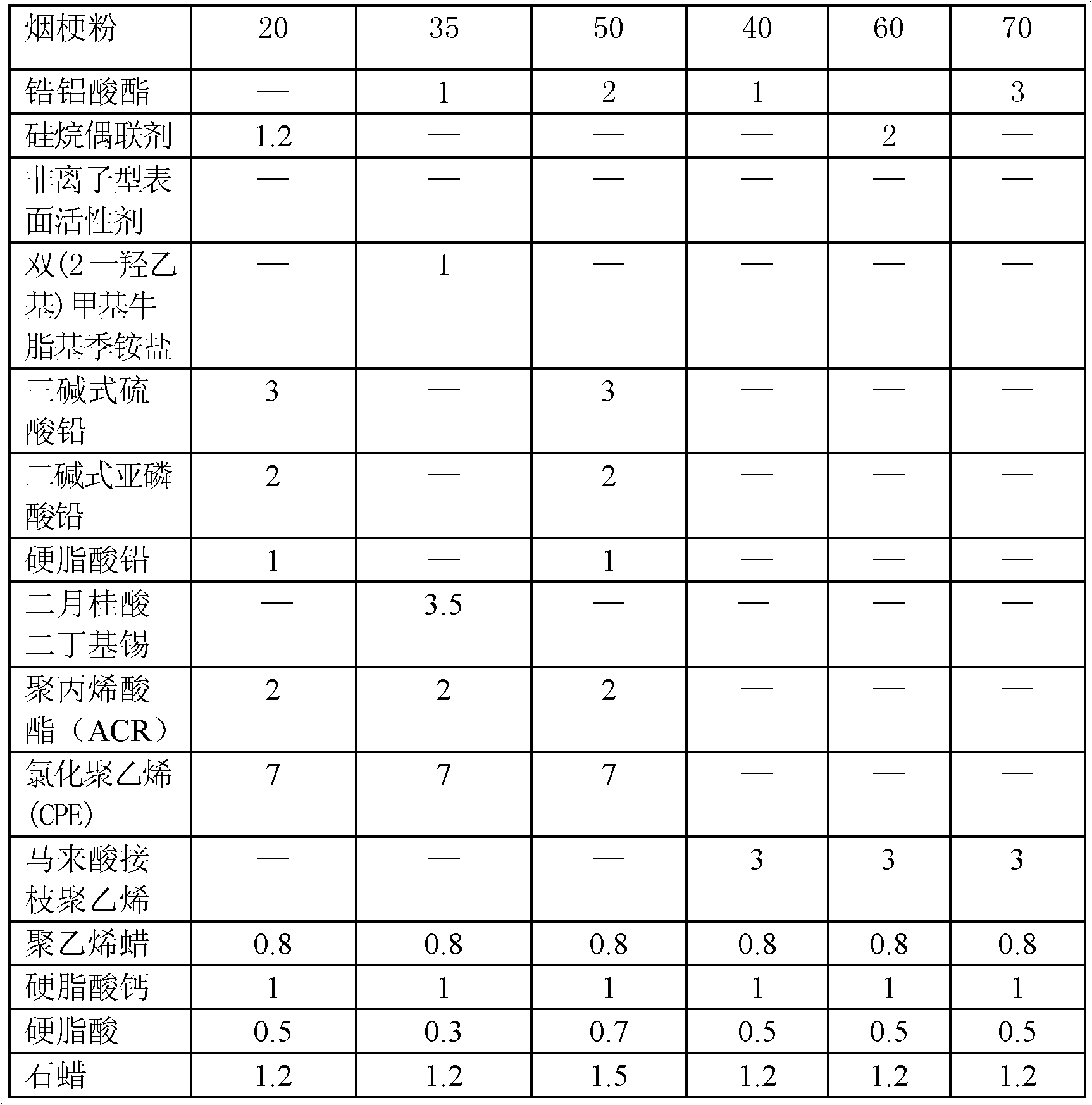

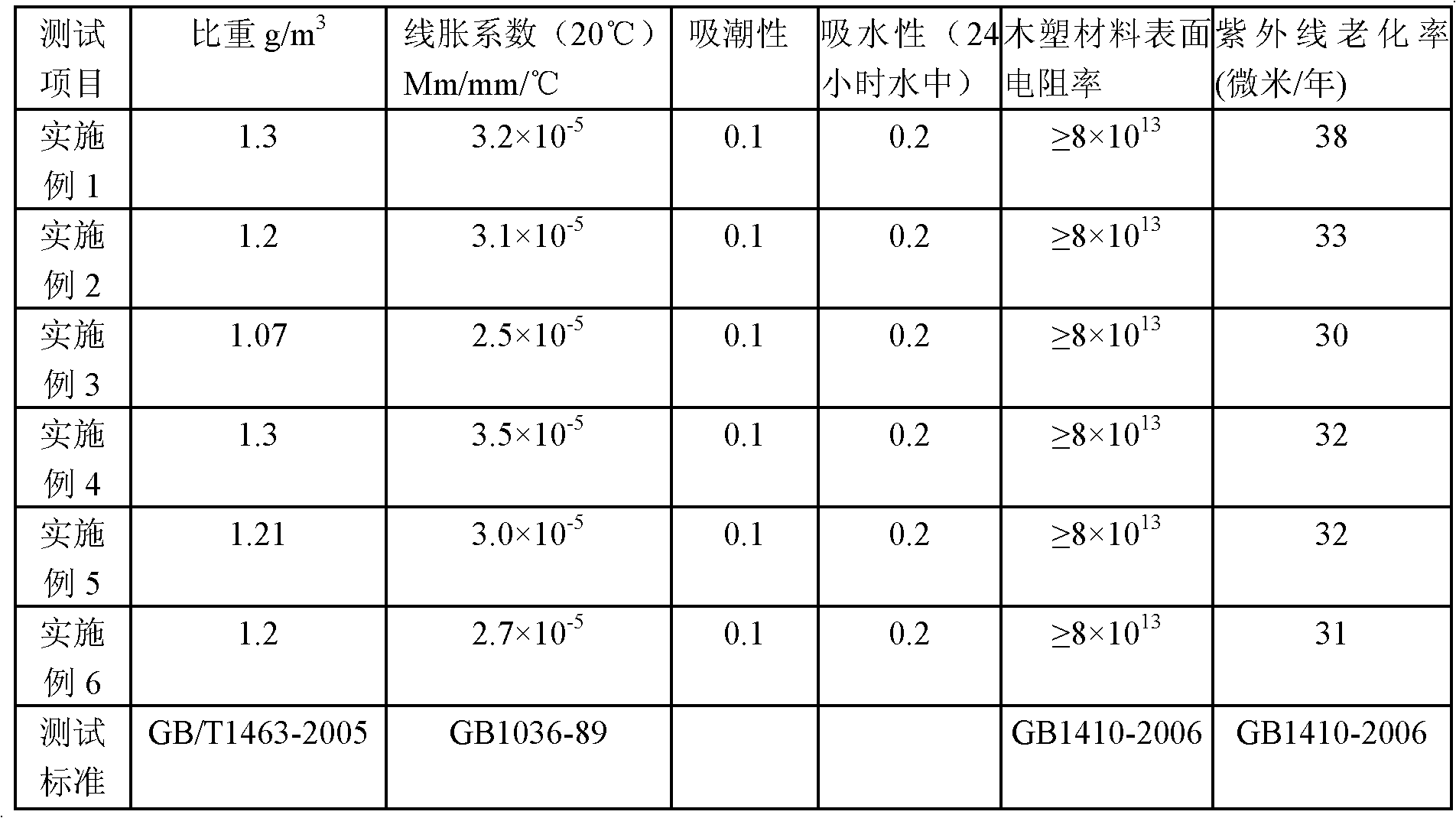

[0026] According to the formula of the tobacco stem wood-plastic composite material shown in Table 1, put the tobacco stems into a 2.5% sodium hydroxide aqueous solution, pass in steam to make the temperature 70-80°C, and soak for 120 minutes to remove the tobacco stems. The tar, nicotine and water-soluble matter are naturally dried to make the water content less than 8%, and the tobacco stems are crushed with a special fiber grinder to make the fineness 60-80 mesh, and forced to dry to make the water content less than 2.5%. And carry out chemical modification treatment on the surface of tobacco stem powder. In the high-speed mixer, nano-montmorillonite is added to the surface-modified tobacco stem powder, and high-speed stirring is performed for 10 to 40 minutes to obtain nano-montmorillonite-wrapped tobacco stem powder; Polyvinyl chloride resin, polymer modifier, heat stabilizer, lubricant and modified nano-montmorillonite are mixed in a high-speed kneader, and the material ...

Embodiment 4 Embodiment 5 Embodiment 6

[0028] According to the formula of the tobacco stem wood-plastic composite material shown in Table 1, put the tobacco stems into a 2.5% sodium hydroxide aqueous solution, pass in steam to make the temperature 70-80°C, and soak for 120 minutes to remove the tobacco stems. The tar, nicotine and water-soluble matter are naturally dried to make the water content less than 8%, and the tobacco stems are crushed with a special fiber grinder to make the fineness 60-80 mesh, and forced to dry to make the water content less than 2.5%. And carry out chemical modification treatment on the surface of tobacco stem powder. In the high-speed mixer, nano-montmorillonite is added to the surface-modified tobacco stem powder, and high-speed stirring is performed for 10 to 40 minutes to obtain nano-montmorillonite-wrapped tobacco stem powder; Polyethylene resin, polymer modifier, lubricant and modified nano-montmorillonite are mixed in a high-speed kneader, and the material is discharged at a temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com