Fluorescent polymer dot, hydrothermal synthesis method through linear non-conjugated polymers and application thereof

A technology of non-conjugated polymers and fluorescent polymers, applied in chemical instruments and methods, luminescent materials, nano-carbons, etc., can solve the problems of complex preparation process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

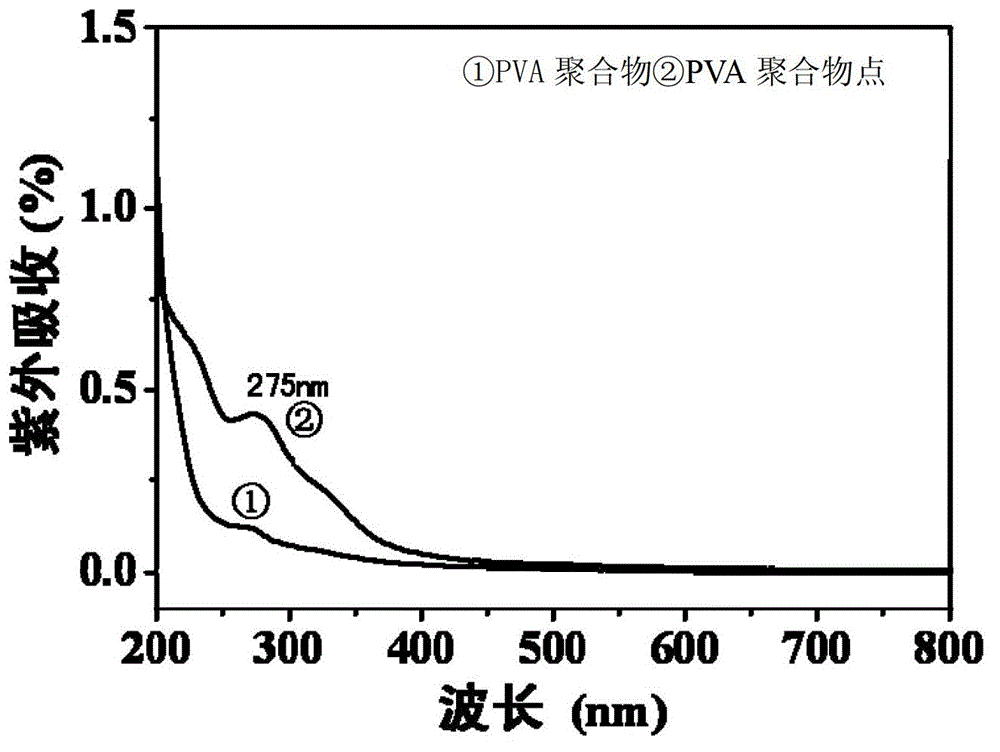

[0028] Weigh 5 g of PVA solid particles (DP=1750±50, Sinopharm Chemical Reagent, its calculated weight average molecular weight is about 80,000) and place it in a beaker, add 100 mL of deionized water and let it swell overnight. Then heat in a water bath at 95° C. with constant stirring until the PVA solid particles are completely dissolved to obtain a PVA aqueous solution with a concentration of 50 mg / mL.

[0029] Measure 10mL of the above aqueous solution, transfer it into a 20mL polytetrafluoroethylene-lined stainless steel reaction kettle, tighten the lid of the kettle, and react at 200°C for 10 hours. After the end, the reactor was naturally cooled to room temperature, and a brownish-yellow liquid was obtained, which was the aqueous solution of polymer dots.

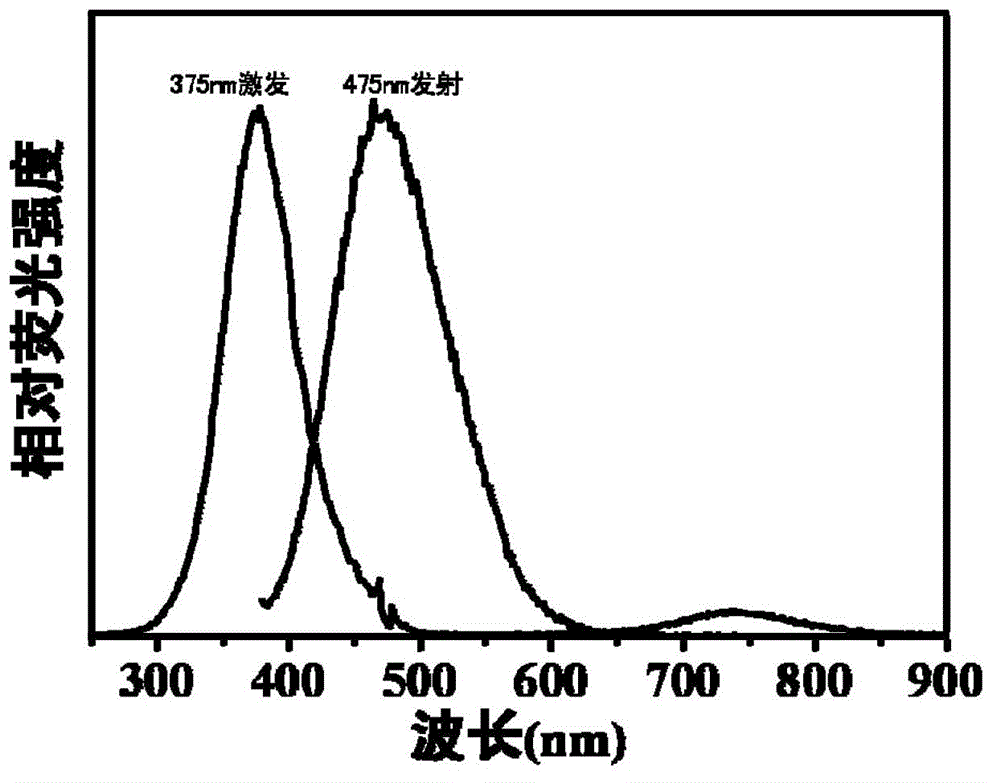

[0030] The fluorescence spectra of the obtained polymer dots ( figure 1 ), the best excitation peak is at 375nm, the best emission peak is at 475nm, and the properties of upconversion can be observed (there is also...

Embodiment 2

[0032] Measure 2 mL of the 50 mg / mL PVA aqueous solution in Example 1, add 48 mL of deionized water, and stir evenly to obtain a PVA aqueous solution with a concentration of 2 mg / mL.

[0033] At the same time, PVA aqueous solutions with concentrations of 0.01 mg / mL, 0.08 mg / mL, 0.4 mg / mL, 10 mg / mL, 50 mg / mL and 100 mg / mL were prepared.

[0034] Measure 10mL of the prepared liquid, transfer it into a 20mL polytetrafluoroethylene-lined stainless steel kettle, tighten the lid of the kettle, and react at 200°C for 10 hours. After the end, the reactor was allowed to cool down to room temperature naturally, and a light yellow liquid was obtained, which was the aqueous solution of polymer dots.

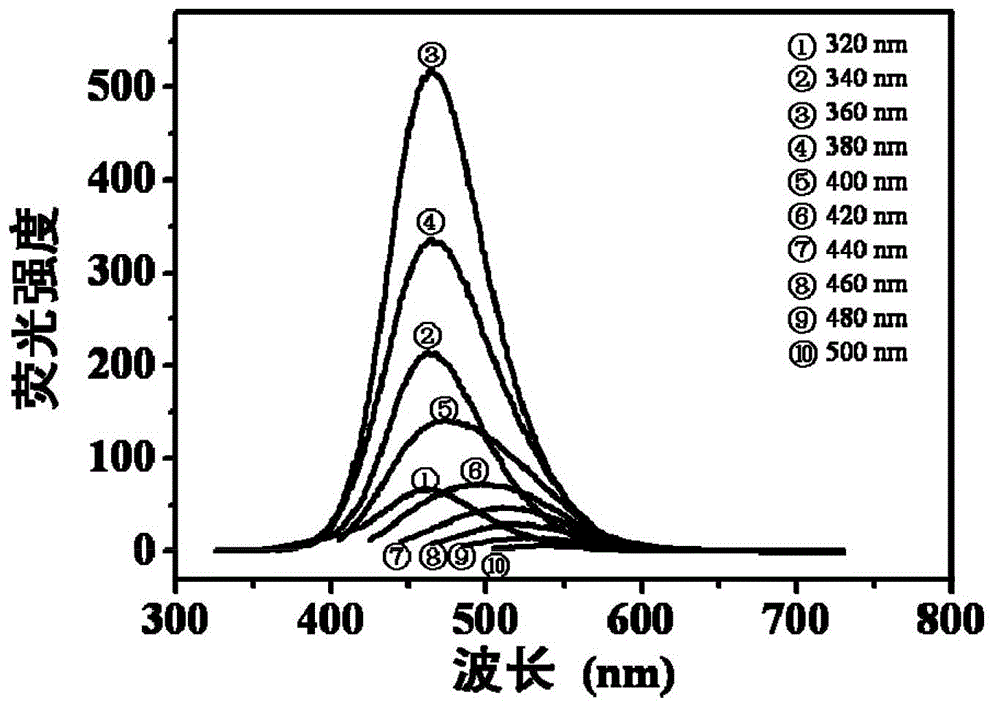

[0035] Changing the initial concentration of PVA will change the fluorescence intensity of the prepared polymer dots ( Figure 9 ), under normal circumstances, the concentration of PVA is large, the carbonization centers generated are many, and the fluorescence generated is strong.

Embodiment 3

[0037] Weigh 5 g of PVA solid powder (MW ≈ 10000, 30000, 80000, 98% alcoholysis, Aldrich) into a beaker, add 100 mL of deionized water, and let it swell overnight. Then heat in a water bath at 95° C. with constant stirring until the PVA solid powder is completely dissolved to obtain a PVA aqueous solution with a concentration of 50 mg / mL.

[0038] Measure 10mL of the prepared liquid, transfer it into a 20mL polytetrafluoroethylene-lined stainless steel kettle, tighten the lid of the kettle, and react at 200°C for 10 hours. After the end, the reactor was naturally cooled to room temperature, and a brownish-yellow liquid was obtained, which was the aqueous solution of polymer dots.

[0039] The fluorescent properties of polymer dots prepared by PVA with different molecular weights are similar ( Figure 10). Under the excitation of 375nm light, the obtained fluorescence emission peaks are located at around 475nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com