Novel vinasse biological feed and production process thereof

A technology of biological feed and production process, applied in animal feed, animal feed, food processing and other directions, can solve the problems of high energy consumption and insufficient conversion of nutrients, and achieve low energy consumption, enhanced digestion, absorption and utilization, and fast growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

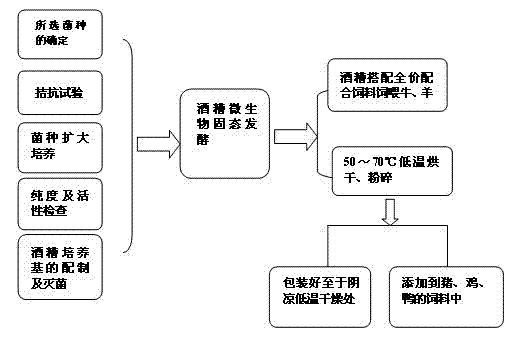

Method used

Image

Examples

Embodiment Construction

[0019] Embodiment of the present invention: The bacterial species combination formula of the production process of processing distiller's grains to produce distiller's grains biological feed of the present invention is: bacterial species include Bacillus subtilis (Ehrenberg) Cohn, Trichoderma viride, acidophilus Lactobacillus acidophilus, Brettanomyces custersianus; the formula of distiller's grains medium is: fresh white distiller's grains 60%, corn flour 10%, rapeseed meal 10%, water 20%, and every 100g of distiller's grains is cultured Add 15 mg of ferrous sulfate, 12 mg of zinc sulfate, 10 mg of manganese sulfate, 15 mg of copper sulfate, and 2 g of calcium hydrogen phosphate to the base.

[0020] The inoculation amount of Bacillus subtilis is 1.5mL of the bacterial liquid per 100g of distiller's grains medium, and the number of viable bacteria is 1.33×10 11 cfu / mL.

[0021] The inoculum amount of Trichoderma viride is 1.5 mL of its bacterial solution per 100 g of distill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com