Preparation method and application of chitosan nanoparticles with pore structures

A technology of chitosan nanoparticles and pore structure, which is applied in the direction of medical preparations of non-active ingredients, pharmaceutical formulas, powder transportation, etc., and can solve product processing difficulties, low concentration of chitosan solution, low production efficiency of nanoparticles, etc. problem, to achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

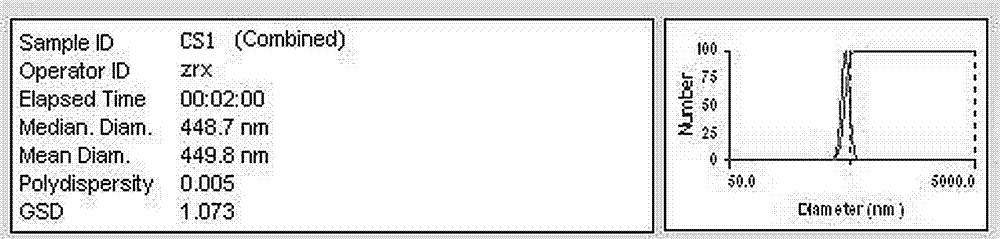

Embodiment 1

[0031] Weigh 770 mg of chitosan with a molecular weight of 55,000 Daltons and a degree of deacetylation of 90%, dissolve it in 30 mL of 1.5% acetic acid solution to obtain a 2.5% chitosan solution; dissolve 1.0 g of Span-80 in 38.6 g liquid paraffin and n-hexane mixed solvent (V 液体石蜡 :V 正己烷 = 4:1) to obtain the oil phase; add the chitosan solution to the oil phase, shear emulsify at 8000rpm for 15min, transfer the obtained miniemulsion into a three-necked flask, stir at 400rpm, and slowly add pentadiol dropwise Aldehyde ether solution (V 25%戊二醛溶液 :V 乙醚 =1:2) 3mL, react at 40°C for 4h, keep the stirring speed at 400rpm, use a circulating water vacuum pump to depressurize and dehydrate, and at the same time increase the system temperature from 40→70°C at a speed of 1°C / min, when there is no water in the condenser tube When flowing out, the obtained chitosan suspension was centrifuged at 8000 rpm for 30 minutes to separate the nanoparticles, the obtained nanoparticles were was...

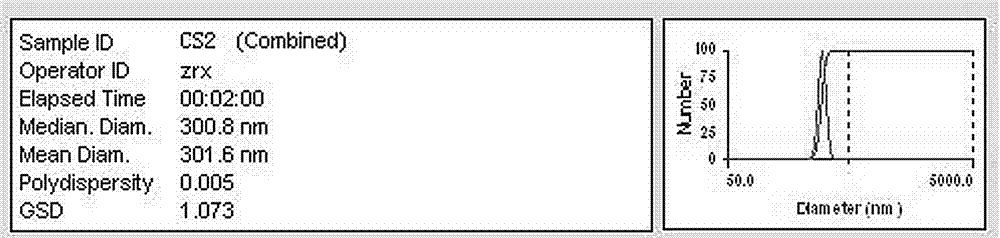

Embodiment 2

[0033] Weigh 460 mg of chitosan with a molecular weight of 150,000 Daltons and a degree of deacetylation of 78%, dissolve it in 30 mL of 1.0% acetic acid solution to obtain a 1.5% chitosan solution; dissolve 1.2 g of Span-80 in 39.0 g liquid paraffin and n-hexane mixed solvent (V 液体石蜡 :V 正己烷 = 4:1) to obtain the oil phase; add the chitosan solution into the oil phase, shear and emulsify at a rate of 10000rpm for 10min, transfer the resulting miniemulsion into a three-necked flask, stir at 500rpm, and slowly add pentadiene Aldehyde ether solution (V 25%戊二醛溶液 :V 乙醚 =1:2) 2mL, react at 50°C for 3h, lower the temperature of the system to 40°C, keep the stirring speed at 500rpm, depressurize and dehydrate the system with a circulating water vacuum pump, and at the same time increase the system temperature from 40→70°C at a speed of 1°C / min , when no water flows out from the condenser tube, the resulting chitosan suspension is centrifuged at a rate of 10,000 rpm for 40 min to sep...

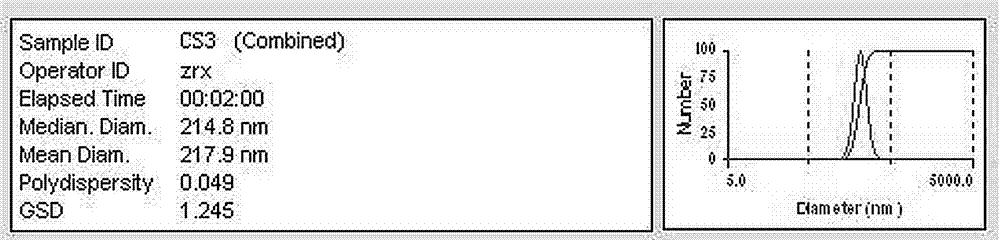

Embodiment 3

[0035] Weigh 300 mg of chitosan with a molecular weight of 210,000 Daltons and a degree of deacetylation of 95%, dissolve it in 30 mL of 1.0% acetic acid solution to obtain a 1.0% chitosan solution; dissolve 1.3 g of Span-80 in 38.8 g liquid paraffin and n-hexane mixed solvent (V 液体石蜡 :V 正己烷 =4:1) to obtain the oil phase; add the chitosan solution into the oil phase, shear emulsify at 12000rpm for 12min, transfer the resulting miniemulsion into a three-necked flask, stir at 500rpm, and slowly add pentadiene Aldehyde ether solution (V 25%戊二醛溶液 :V 乙醚 =1:2) 2mL, react at 60°C for 2h, lower the temperature of the system to 40°C, keep the stirring speed at 500rpm, depressurize and dehydrate the system with a circulating water vacuum pump, and at the same time increase the system temperature from 40→70°C at a speed of 2°C / min , when no water flows out from the condenser tube, the resulting chitosan suspension is centrifuged at a rate of 12000 rpm for 40 min to separate the nanopa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com