Preparation method for nitrogen-rich ZMOF type metal-organic framework porous material

A metal-organic framework, porous material technology, applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of structural damage, low adsorption capacity and selectivity, and poor chemical stability. , to achieve the effect of good physical and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

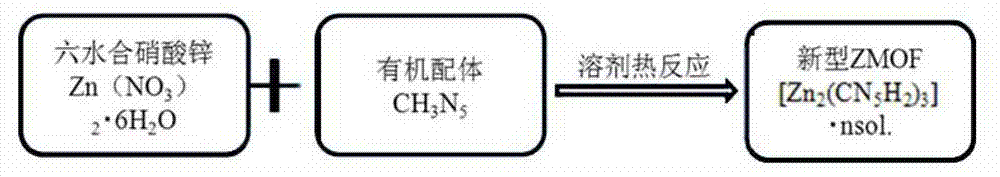

[0018] The specific conditions for the synthesis of the novel nitrogen-enriched ZMOF metal-organic framework porous material prepared in the present invention will be further described in detail below. In this example, the synthesis conditions for the nitrogen-enriched ZMOF type metal-organic framework porous material are as follows:

[0019] The organic ligand nitrogen-containing organic compound used in the reaction is CH 3 N 5 (0.51g);

[0020] Metal zinc salt is zinc nitrate hexahydrate (Zn(NO 3 ) 2 ●6H 2 O) (0.895g);

[0021] The organic solvent was N,N-dimethylformamide (DMF) (30ml).

[0022] use as figure 1 Shown synthetic route, concrete preparation process is as follows:

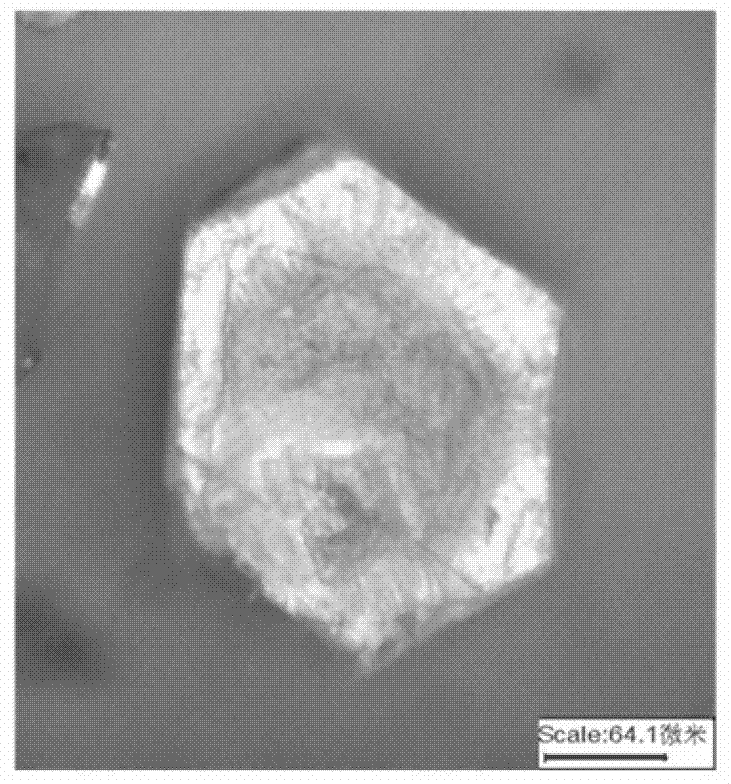

[0023] Measure 15ml of DMF in a polytetrafluoroethylene high-temperature reaction kettle, and sequentially weigh 0.51g of nitrogen-containing organic compound CH 3 N 5 With 0.895g zinc nitrate hexahydrate (Zn(NO 3 ) 2 ●6H 2 O), pour it into the reaction kettle, add 15ml of DMF, stir eve...

Embodiment 2

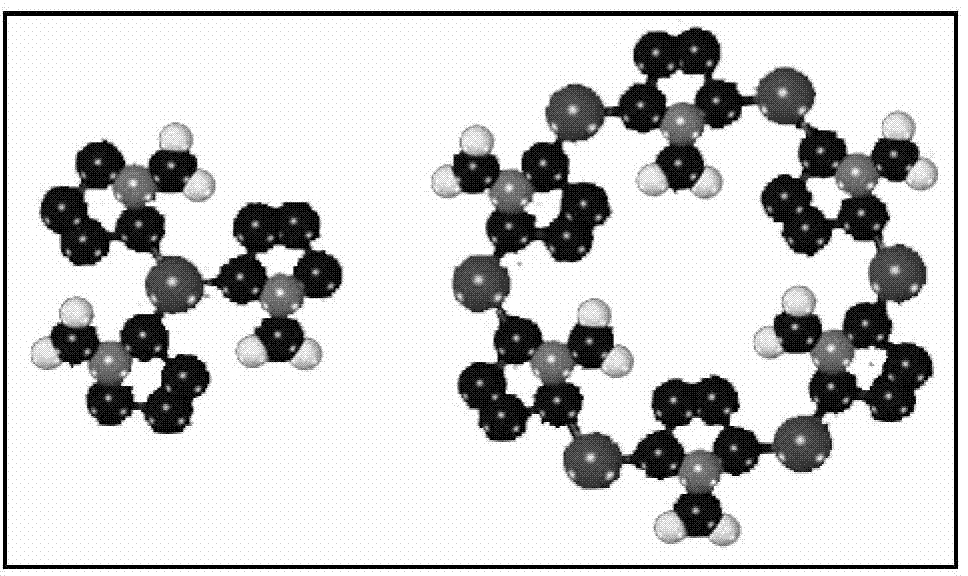

[0032]In this example, the preparation method of the novel nitrogen-enriched ZMOF type metal-organic framework porous material is basically the same as that of Example 1, except that CH 3 N 5 4H 2 O instead of CH 3 N 5 , the nitrogen-enriched ZMOF type metal-organic framework porous material with regular morphology can also be obtained. This material has certain thermodynamic and chemical stability, and is resistant to CO 2 The gas has a strong selective adsorption capacity, so it can 2 The field of capture and separation technology, the separation of organic molecules, the packing of chromatographic packed columns, and the preparation of membrane materials such as gas separation membranes, liquid separation membranes and nanocomposite films have good application prospects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com