Advanced treatment method of ethylene waste lye

A technology for advanced treatment of ethylene waste lye, applied in chemical instruments and methods, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc., can solve high organic pollutant content, low wastewater treatment efficiency, external drainage Exceeding the standard and other problems, to achieve the effect of shortening the response time, shortening the processing process, and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

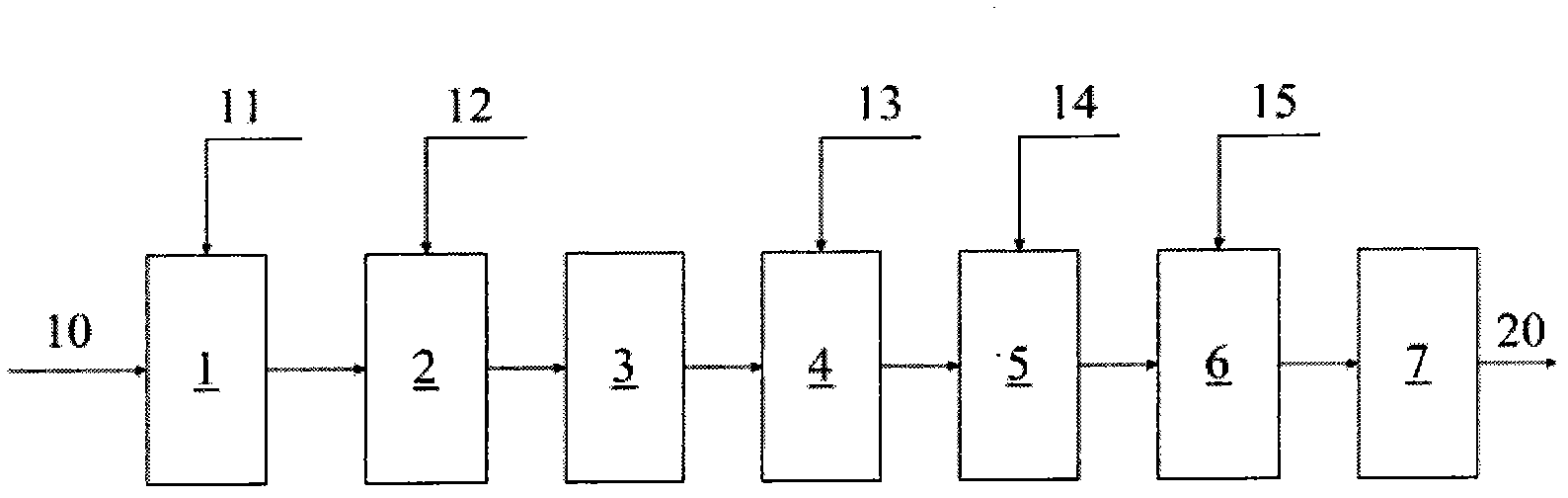

Method used

Image

Examples

Embodiment 1

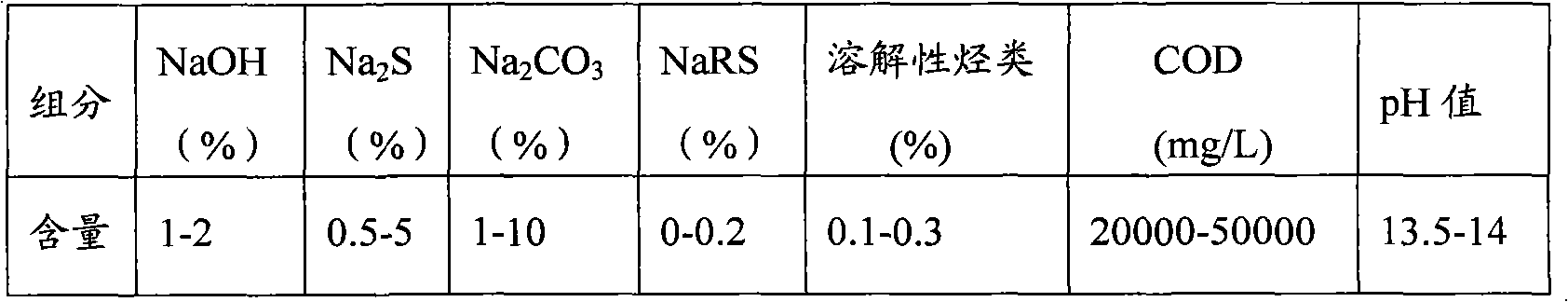

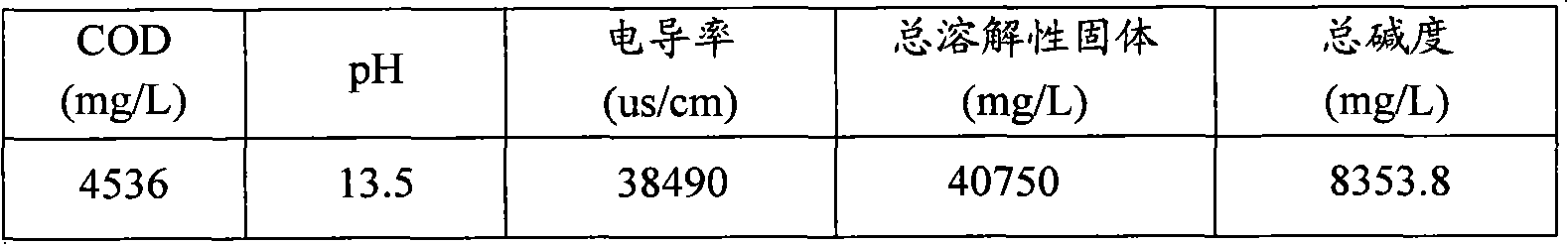

[0037] The waste ethylene lye (see Table 2 for its composition) after the wet oxidation treatment is discharged into the pH value adjustment pool, and concentrated sulfuric acid is added to adjust it into wastewater with a pH value of 8.5. Then the waste water is discharged into the first-level aerobic biochemical reaction tank, and potassium dihydrogen phosphate is added in an amount of 100:2 based on the mass ratio of waste water influent COD and phosphorus element, and at a sludge concentration of 5-6g / L, the dissolved oxygen concentration is 4-5mg / L, the temperature is 20-30°C, and the pH value is 8.5 for 24 hours. After that, discharge the wastewater into the first secondary sedimentation tank for precipitation, and discharge the supernatant into the Fenton oxidation unit. First, add concentrated sulfuric acid to the discharged wastewater to adjust the pH value to 3.0, and then add ferrous sulfate in turn (FeSO 4 ·7H 2 O) and hydrogen peroxide (H 2 o 2 ), where Fe 2...

Embodiment 2

[0044] The waste ethylene lye (see Table 4 for its composition) after the wet oxidation treatment is discharged into the pH value adjustment pool, and concentrated sulfuric acid is added to adjust it into wastewater with a pH value of 9.5. Then the waste water is discharged into the first-level aerobic biochemical reaction tank, and sodium dihydrogen phosphate is added in an amount of 100:3 based on the mass ratio of waste water influent COD and phosphorus element, and at a sludge concentration of 6-8g / L, dissolved oxygen concentration 4-6mg / L, temperature 20-30°C, pH 9.5 for 48 hours. After that, discharge the wastewater into the first secondary sedimentation tank for precipitation, and discharge the supernatant into the Fenton oxidation unit. First, add concentrated sulfuric acid to the discharged wastewater to adjust the pH value to 3.5, and then add ferrous sulfate in turn. (FeSO 4 ·7H 2 O) and hydrogen peroxide (H 2 o 2 ), where Fe 2+ / H 2 o 2 The mass concentrati...

Embodiment 3

[0051] The waste ethylene lye (see Table 6 for its composition) after the wet oxidation treatment is discharged into the pH value adjustment tank, and concentrated sulfuric acid is added to adjust it into wastewater with a pH value of 9.0. Then the waste water is discharged into the first-level aerobic biochemical reaction tank, and potassium dihydrogen phosphate is added in an amount of 100:5 based on the mass ratio of waste water influent COD and phosphorus element, and when the sludge concentration is 5-6g / L, the dissolved oxygen concentration is 4-5mg / L, the temperature is 20-30°C, and the pH value is 9.0 for 36 hours. After that, discharge the wastewater into the first secondary sedimentation tank for precipitation, and discharge the supernatant into the Fenton oxidation unit. First, add concentrated sulfuric acid to the discharged wastewater to adjust the pH value to 3.5, and then add ferrous sulfate in turn. (FeSO 4 ·7H 2 O) and hydrogen peroxide (H 2 o 2 ), where ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com