Preparation method of dimethyldiallylammonium chloride

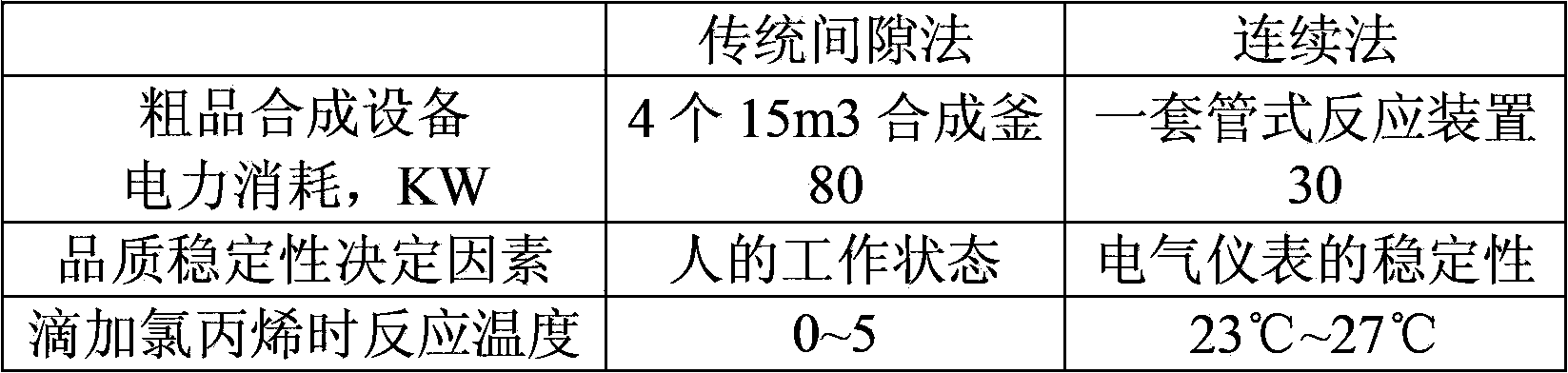

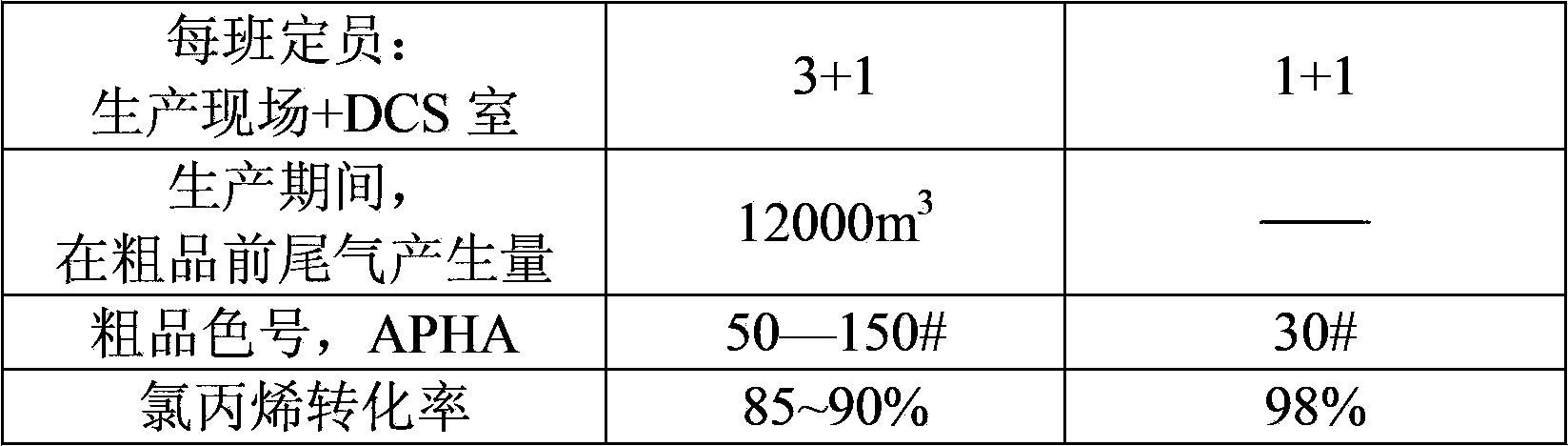

A technology of dimethyl diallyl ammonium chloride and allyl chloride, which is applied in the preparation of amino compounds, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problem of reducing product quality, reducing product yield and reducing allyl chloride. and other problems, to achieve the effect of eliminating errors and deviations, reducing the production of three wastes, and reducing the refrigeration load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

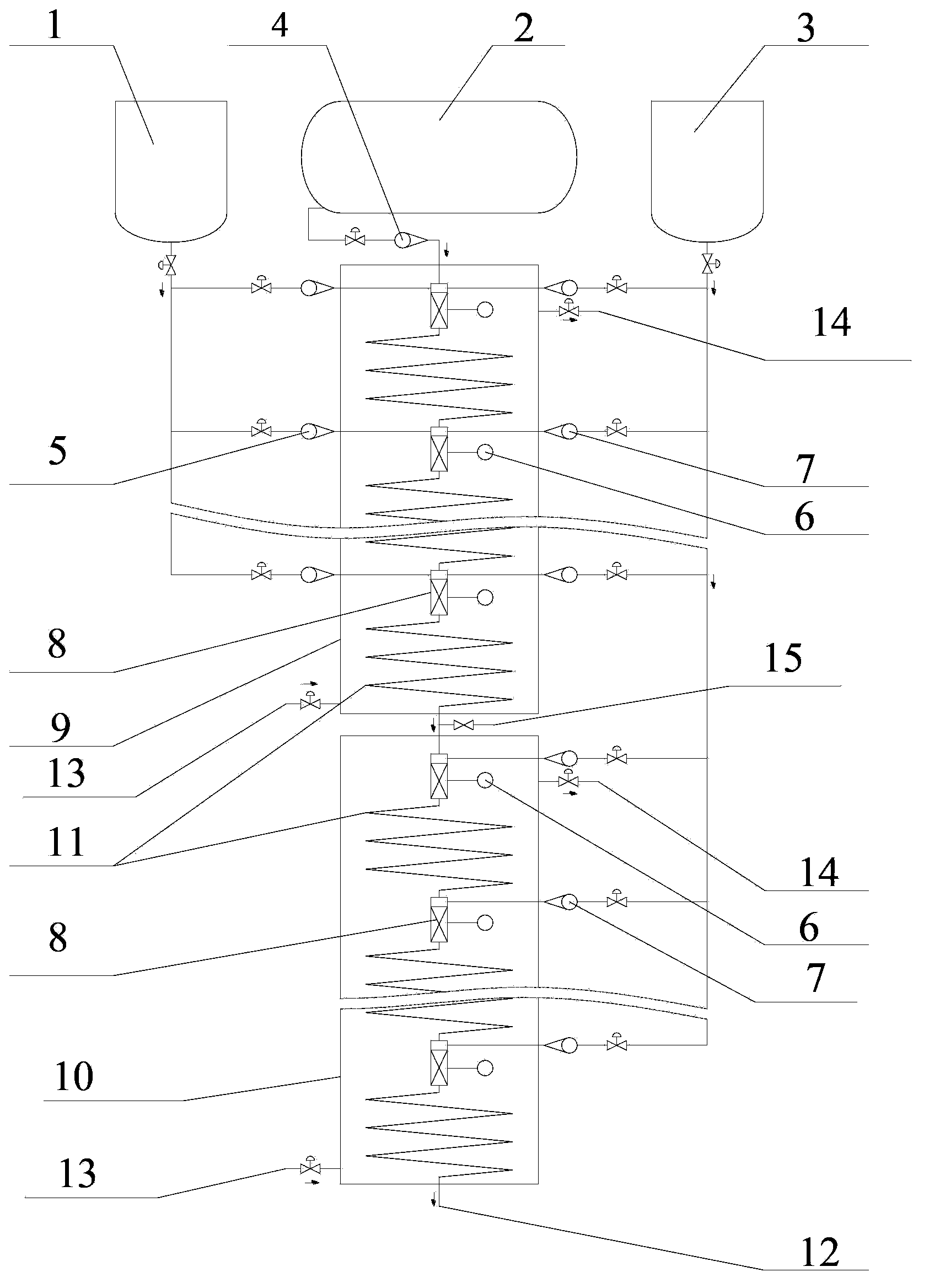

[0030] The present invention will be further described in detail through specific implementation below in conjunction with the accompanying drawings.

[0031] exist figure 1 Among them, the first constant temperature tank 9 and the second constant temperature tank 10 are respectively equipped with 8 reactor units, that is, n=m=8. The reactor unit consists of Titanium tubes as static mixers 8 and 622 meters Made of titanium tube 11;

[0032] The static mixer 8 of the first reactor unit is communicated with the dimethylamine header tank 2 by a branch pipe; dimethylamine is provided between the dimethylamine header tank 2 and the static mixer 8 of the first reactor unit metering valve 4;

[0033] The static mixer 8 of the reactor unit soaked in the first constant temperature tank 9 communicates with the allyl chloride head tank 1 and the sodium hydroxide aqueous solution head tank 3 respectively through branch pipes, and each static mixer 8 is connected to the allyl chlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com