Method for preparing high-purity daptomycin

A daptomycin, high-purity technology, applied in the field of preparation of high-purity daptomycin, can solve the problems of daptomycin difficult to achieve large-scale production, no post-industrial extraction technology, no good industrial production strains, etc. , achieve the effect of shortening the process cycle, stable sample yield and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

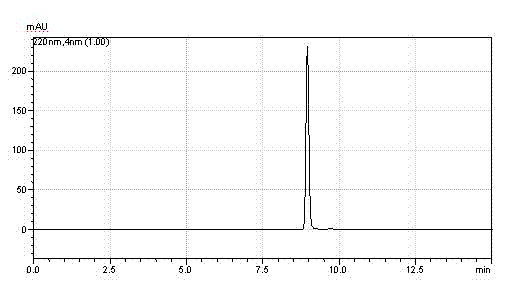

Image

Examples

Embodiment 1

[0025] Take 100 L of daptomycin fermentation broth with a fermentation unit of 1960 μg / mL, add 3000 g of perlite as a filter aid to the above fermentation broth, stir for 1 hour, and then plate and frame filter to obtain daptomycin filtrate. Introduce the daptomycin filtrate into a macroporous resin D312 column (loading capacity: 20L) at a flow rate of 40L / h for adsorption and enrichment. The flow rate was controlled at 10 L / h, and the collection was started when the concentration of daptomycin in the desorbed liquid detected by HPLC was higher than 200 μg / mL, and the collection was stopped when the concentration was lower than 200 μg / mL. The collected desorbed solution was concentrated under reduced pressure until the concentration of daptomycin was 120 g / L to obtain a concentrated solution of daptomycin. Then slowly add acetone of 7 times the volume of the concentrated solution for crystallization, filter the crystallized solution, and dry at 45°C to obtain 195 g of crude da...

Embodiment 2

[0028] 10 L of daptomycin fermentation broth with a fermentation unit of 2060 μg / mL was used, and 100 g of perlite was added to the fermentation broth as a filter aid, stirred for 30 minutes and then vacuum filtered to obtain a daptomycin filtrate. This daptomycin filtrate is introduced into a macroporous resin LX-50 column with a loading capacity of 2000mL at a flow rate of 4L / h for adsorption and enrichment. After the adsorption is completed, it is washed with methanol aqueous solution with a volume concentration of 30%, and then washed with a volume concentration of 30%. 70% methanol aqueous solution was used for desorption, and the desorption flow rate was controlled at 1 L / h. When the concentration of daptomycin in the desorption liquid detected by HPLC was higher than 200 μg / mL, the desorption liquid was collected, and when the concentration was lower than 200 μg / mL, the collection was stopped. Concentrate the above desorption solution under reduced pressure at 50°C until...

Embodiment 3

[0031] Take 10 L of daptomycin fermentation broth with a fermentation unit of 2300 μg / mL, add 200 g of diatomaceous earth as a filter aid to the fermentation broth, stir for 30 minutes, and then vacuum filter to obtain daptomycin filtrate. The filtrate was introduced into a macroporous resin D113 column with a capacity of 2000mL at a flow rate of 4L / h for adsorption and enrichment. After the adsorption was completed, it was first washed with 40% ethanol aqueous solution, and then desorbed with 75% ethanol aqueous solution. The desorption flow rate was controlled at 1L / h h, when the concentration of daptomycin in the desorbed solution detected by HPLC was higher than 200 μg / mL, the collection was started, and when the concentration was lower than 200 μg / mL, the collection was stopped. After the desorption is completed, the collected desorption liquid is concentrated under reduced pressure to a concentration of 110 g / L of daptomycin, and then slowly add isopropanone in an amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com