Preparation method of pepper oleoresin

A production method and technology of pepper oil, applied in the direction of fat oil/fat production, fat production, food preparation, etc., can solve the problems of high extraction cost and complicated extraction process, and achieve short extraction time, sufficient spicy taste, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

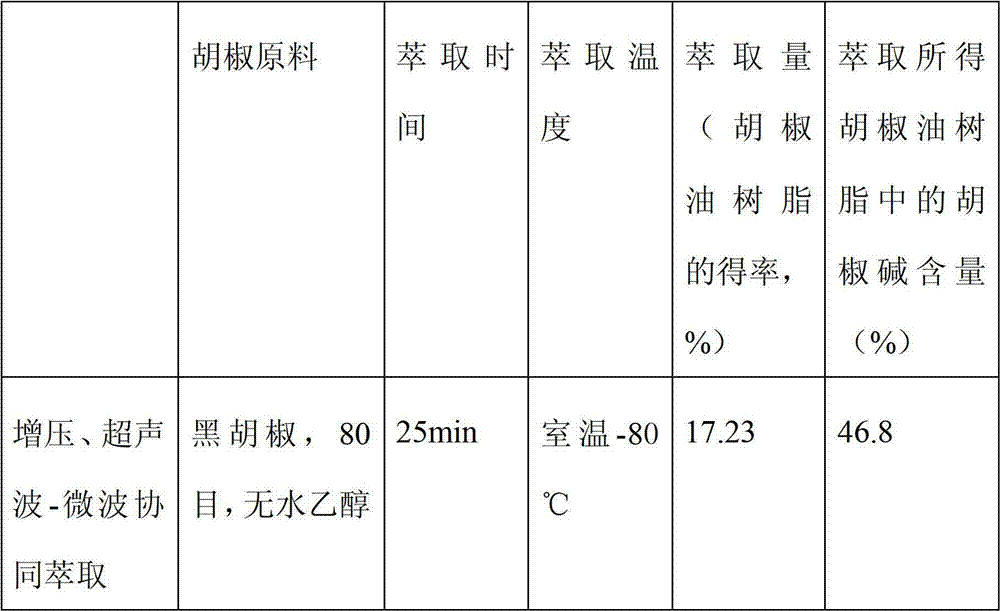

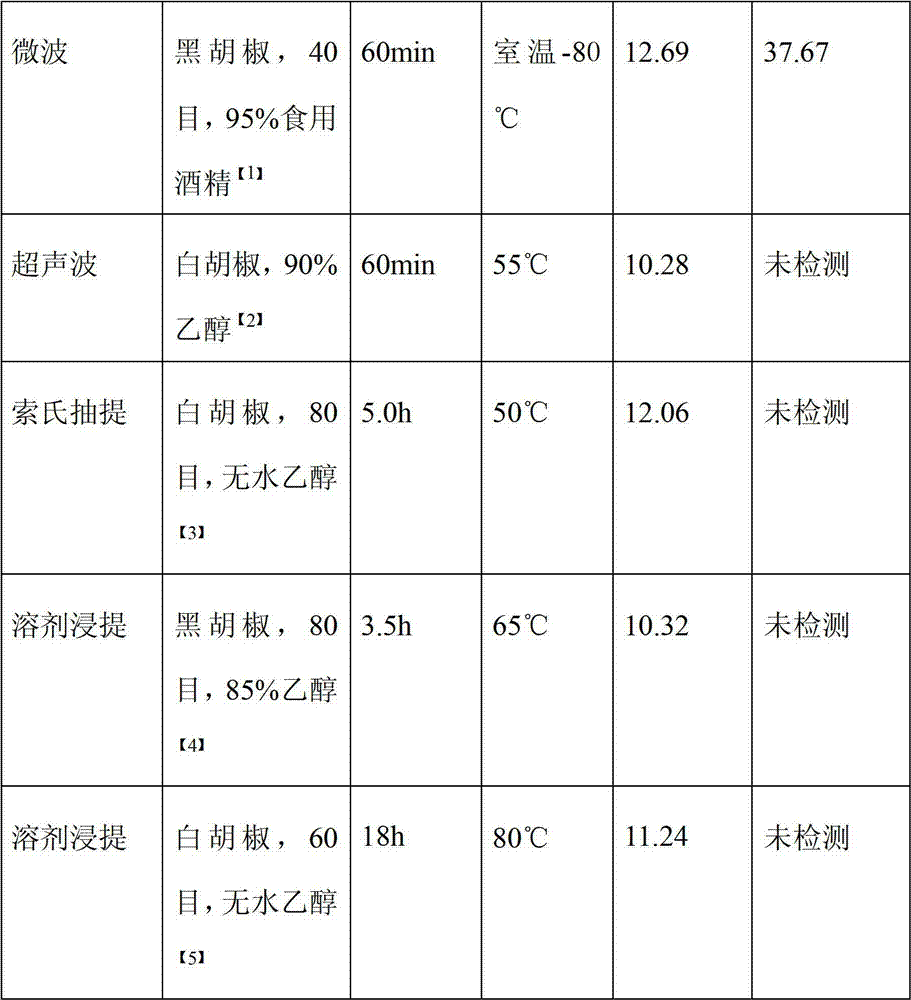

Image

Examples

Embodiment 1

[0028] The preparation method of pepper oleoresin, its raw material is: 10 parts of black peppercorns, 400 parts of 95% edible alcohol.

[0029] The preparation method of described pepper oleoresin, comprises the steps:

[0030] (1) To prepare pepper powder, use black pepper with a moisture content lower than 12% as raw material, and grind it to a diameter of 0.50 mm with a pulverizer;

[0031] (2) Add solvent, add 400 parts of 95% edible alcohol to 10 parts of pepper;

[0032] (3) Program pressurized fast solvent extraction, the pressure range is controlled at 6-8bar, room temperature-programmed pressurization method is adopted, the pressure extraction time is 1.5min each time, intermittent extraction is 1.5min, repeat cycle 5 times, and collect after extraction Raw material and filtrate;

[0033] (4) Ultrasonic-microwave synergistic extraction, ultrasonic power / frequency: 50W / 40KHz, microwave power: 70W, microwave frequency: 2450MHz, synergistic extraction for 10min;

[0...

Embodiment 2

[0043] Pepper oleoresin, its raw material is: 10 parts of white peppercorns, 100 parts of 95% edible alcohol.

[0044] The preparation method of described pepper oleoresin, comprises the steps:

[0045] (1) To prepare pepper powder, use white pepper with a moisture content of less than 12% as raw material, and grind it to a diameter of 0.15mm with a pulverizer;

[0046] (2) Add solvent, add 100 parts of 95% edible alcohol to 10 parts of white pepper powder;

[0047] (3) Program pressurized fast solvent extraction, the pressure range is controlled at 6-8bar, room temperature-programmed pressurization method is adopted, the pressure extraction time is 2.0min each time, intermittent extraction is 1.0min, repeat cycle 10 times, and collect after extraction Raw material and filtrate;

[0048] (4) Ultrasonic-microwave synergistic extraction, ultrasonic power / frequency: 50W / 40KHz, microwave power: 300W, microwave frequency: 2450MHz, synergistic extraction for 10min;

[0049] (5) F...

Embodiment 3

[0054] Pepper oleoresin, its raw material is: 10 parts of green pepper grains, 500 parts of 60% edible alcohol.

[0055] The preparation method of described pepper oleoresin, comprises the steps:

[0056] (1) To prepare pepper powder, use green pepper with a moisture content lower than 12% as raw material, and grind it to a diameter of 0.85mm with a pulverizer;

[0057] (2) Add solvent, add 500 parts of 60% edible alcohol to 10 parts of green pepper powder;

[0058] (3) Program pressurized fast solvent extraction, the pressure range is controlled at 6-8bar, room temperature-programmed pressurization method is adopted, the pressure extraction time is 2.0min each time, intermittent extraction is 1.0min, repeat cycle 10 times, and collect after extraction Raw material and filtrate;

[0059] (4) Ultrasonic-microwave synergistic extraction, ultrasonic power / frequency: 50W / 40KHz, microwave power: 500W, microwave frequency: 2450MHz, synergistic extraction for 20min;

[0060] (5) Fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com