Method for preparing indium target metal film

A metal thin film, indium target technology, applied in metal material coating process, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of slow metal thin film coating rate, rough surface of precursors, low production efficiency, etc. To achieve the effect of reducing surface roughness and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

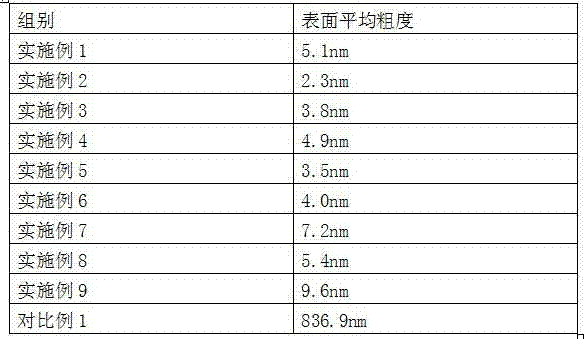

Examples

Embodiment 1

[0012] A method for preparing an indium target metal thin film, adding copper with an atomic percentage of 2% to indium metal to make a target with a diameter of 3 inches for the sputtering process, and putting the required coated glass substrate into the sputtering chamber In the body, the background pressure of the sputtering chamber was evacuated to 0.7×10 by a vacuum pumping system. -5 After torr, argon is used as the working gas, and argon is introduced through the throttle valve to control the working pressure of the sputtering chamber to be 1×10 -2 torr, a sputtering process was performed for 60 minutes with a DC power of 100 watts to prepare a planarized indium metal film.

Embodiment 2

[0014] A method for preparing an indium target metal thin film, adding copper with an atomic percentage of 6% to indium metal to make a target with a diameter of 3 inches for the sputtering process, and putting the required coated glass substrate into the sputtering chamber In the body, the background pressure of the sputtering chamber was evacuated to 0.8×10 by a vacuum pumping system. -5 After torr, argon is used as the working gas, and argon is introduced through the throttle valve to control the working pressure of the sputtering chamber to be 1×10 -2 torr, a sputtering process was performed for 60 minutes with a DC power of 100 watts to prepare a planarized indium metal film.

Embodiment 3

[0016] A method for preparing an indium target metal film, adding copper with an atomic percentage of 10% to indium metal to make a target with a diameter of 3 inches for the sputtering process, and putting the required coated glass substrate into the sputtering chamber In the body, the background pressure of the sputtering chamber was evacuated to 0.9×10 by a vacuum pumping system. -5 After torr, argon is used as the working gas, and argon is introduced through the throttle valve to control the working pressure of the sputtering chamber to be 1×10 -2 torr, a sputtering process was performed for 60 minutes with a DC power of 100 watts to prepare a planarized indium metal film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com