Sample treatment method for measuring niobium, tungsten and zirconium in steel

A processing method and a certain amount of technology, applied in the field of measurement, can solve the problems of phosphorus pollution in the sampling system, blockage of the atomization system and ICP torch, and difficulty in popularization, and achieve the effects of avoiding phosphorus pollution, reducing matrix effect interference, and avoiding clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

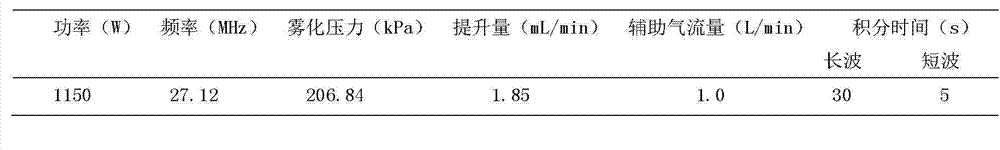

[0018] Embodiment 1 is the determination of the content of niobium, tungsten and zirconium in the standard sample of medium and low alloy steel by using the present invention. The specific method is as follows:

[0019] 1. Prepare soluble acid

[0020] Measure 100 mL of sulfuric acid (sulfuric acid with a density of 1.84 g / mL) in a 100 mL measuring cup, pour it along the glass rod into a 1 L beaker filled with 400 mL of deionized water, and gently stir and mix with the glass rod. After the solution was cooled to room temperature, it was poured into a 1 L wide-mouth ground bottle to obtain soluble acid for use.

[0021] 2. Preparation of ammonium oxalate complexing agent

[0022] Weigh 4.0 g of ammonium oxalate on a tray balance and dissolve it in a 1 L beaker filled with 1000 mL of deionized water, stir gently with a glass rod to dissolve completely, then pour it into a 1 L wide-mouth grinding bottle to obtain the concentration It is the ammonium oxalate complexing agent of...

Embodiment 2

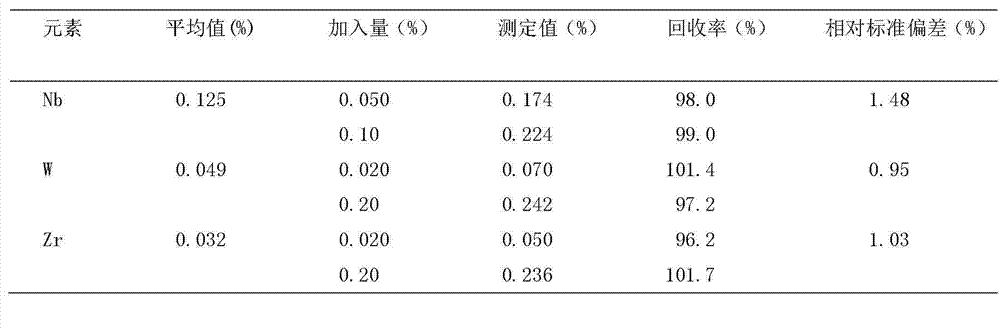

[0043] Embodiment 2 is the determination of the content of niobium, tungsten and zirconium in alloy steel samples by using the present invention. The specific method is as follows:

[0044] 1. Prepare dissolving acid (as in Example 1)

[0045] 2. Preparation of ammonium oxalate complexing agent (as in Example 1)

[0046] 3. Dissolve the sample

[0047] Accurately weigh 0.2000g of 1# sample and place it in a 125 ml conical flask, add 25 mL of dissolving acid (concentration: sulfuric acid: water = 1:4), heat to dissolve, add nitric acid dropwise for oxidation, continue heating until sulfuric acid smokes , the salts were precipitated, removed, cooled slightly, then added 15 mL of ammonium oxalate complexing agent (concentration: 4 g / L), heated to dissolve the salts, removed, cooled to room temperature, transferred to a 50 mL volumetric flask, and deionized Dilute to volume with water and mix well.

[0048] 4. Draw the working curve

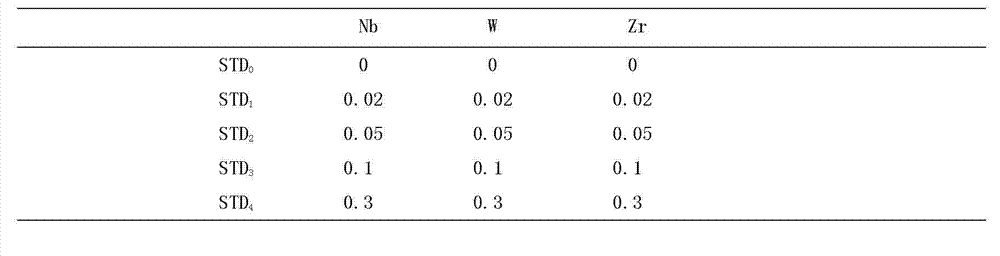

[0049]Weigh 5 parts of 0.2000 g high-puri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com