Laser scribing method of transparent thin film solar cell

A technology of solar cells and thin films, applied in photovoltaic power generation, renewable energy integration, circuits, etc., can solve the problems of limited usable range and poor light transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

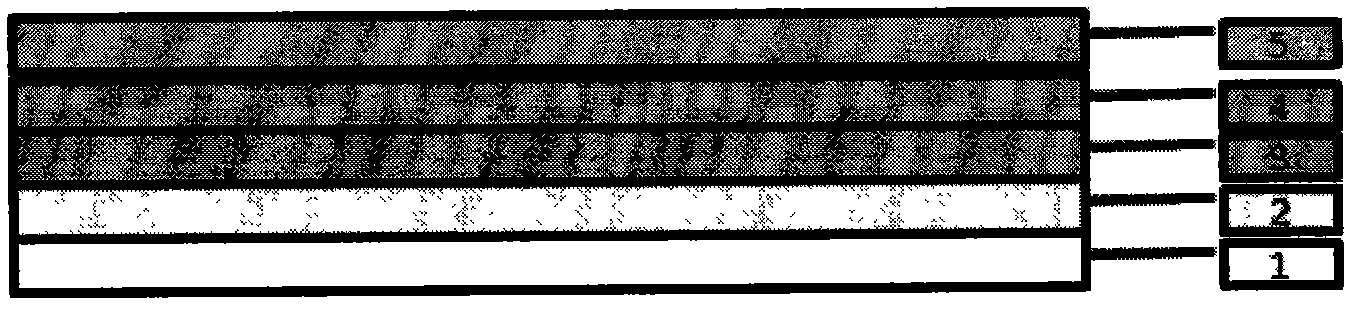

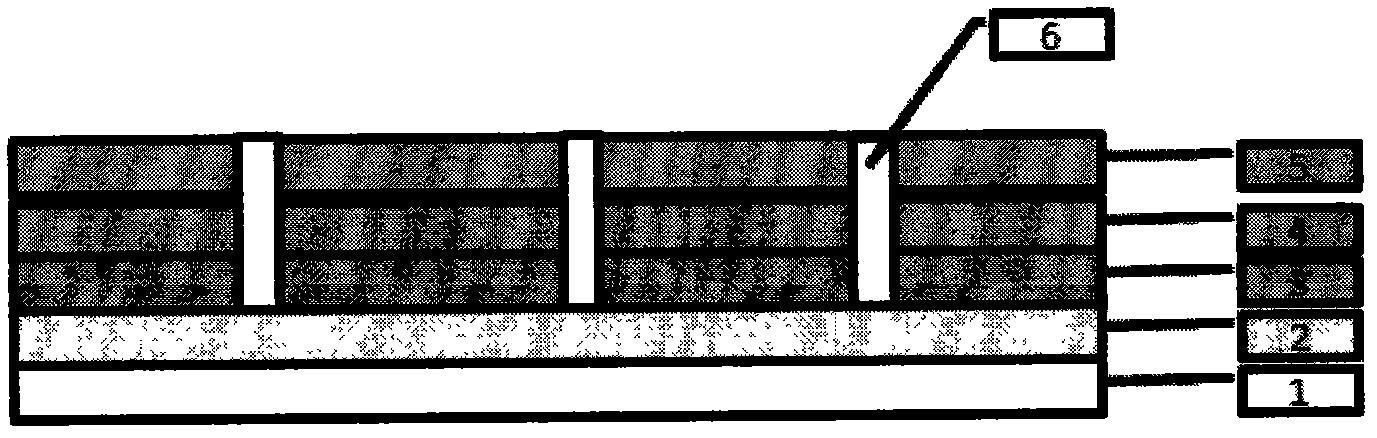

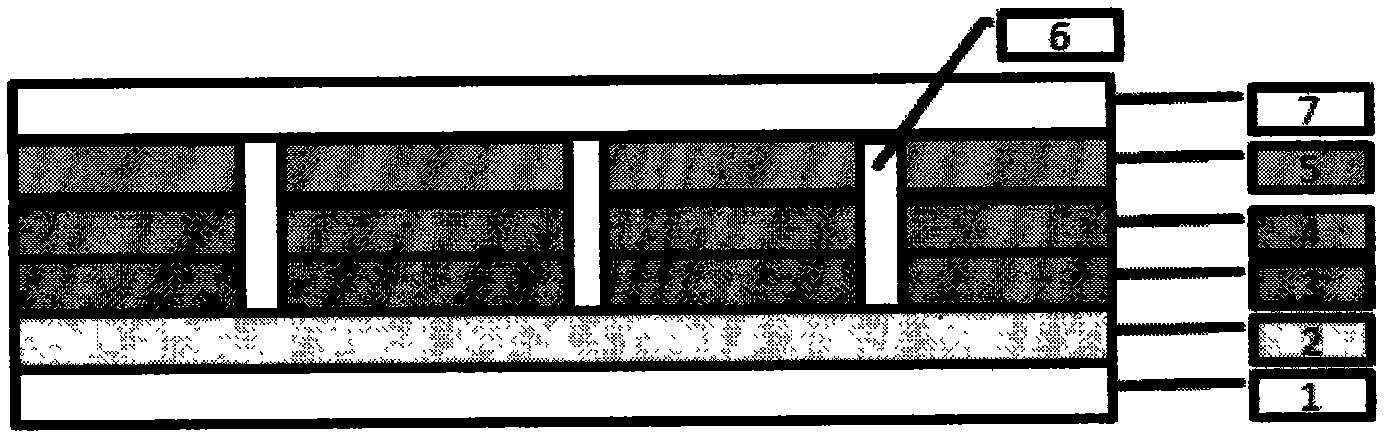

[0004] From Figure 1 to Figure 3, it can be found that the main components of thin film solar cell preparation are transparent substrate, transparent conductive film, amorphous silicon film, microcrystalline silicon film, transparent back electrode film and transparent back plate. Wherein the transparent substrate, the material of the transparent substrate can be glass, quartz, single crystal alumina, transparent plastic or flexible transparent material. The laser scribing technology of a light-transmitting thin-film solar cell of the present invention is hereby combined with the accompanying drawings, and the details are as follows: Please refer to FIG. 1, which is a brief description of a thin-film solar cell. The method is to carry out chemical vapor deposition on a transparent substrate 1 deposition method or sputtering method... etc., the transparent conductive film 2 is prepared by a market-recognized method, and then the amorphous silicon thin film 3 is prepared by a pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com