Coated granules containing natural oregano oil for birds and preparation method thereof

A granule and genol technology, which is applied in the field of poultry coated granules and its preparation, can solve the problems of restricting the release and bioavailability of oregano genol, low coating rate of oregano genol, serious volatilization, etc. Achieve the effect of convenient production, good fluidity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

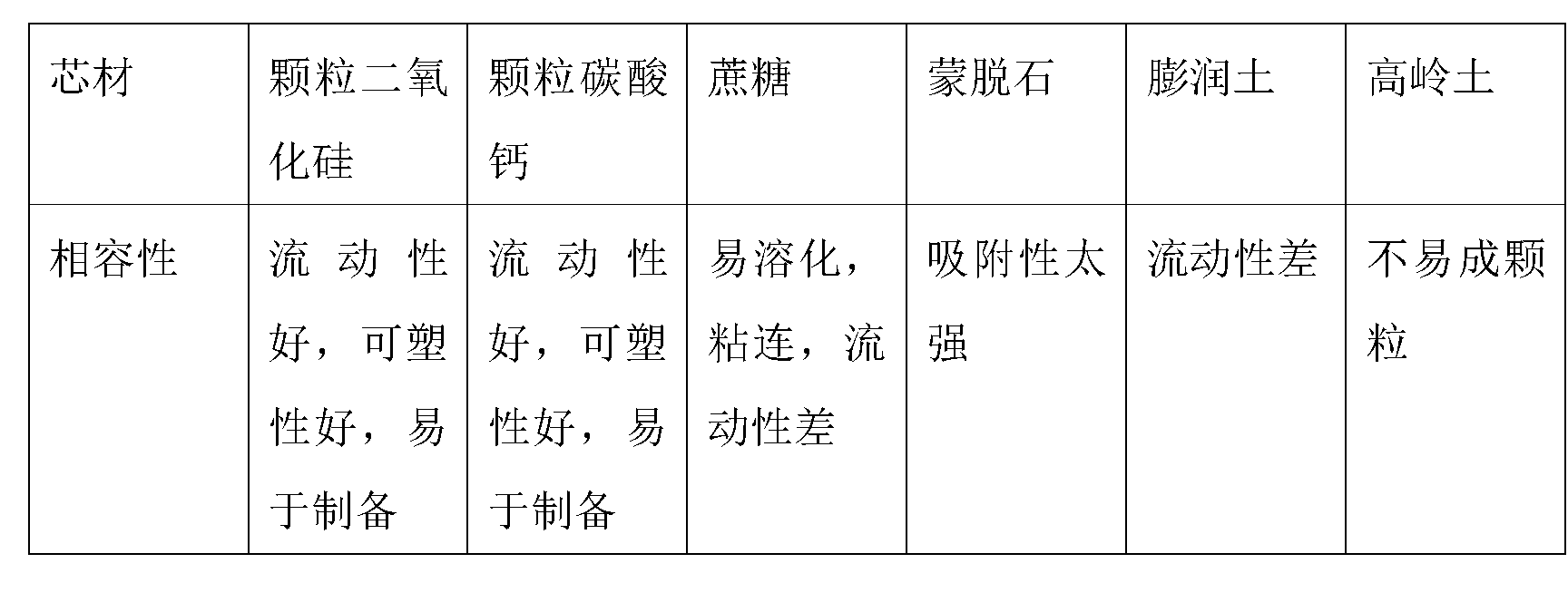

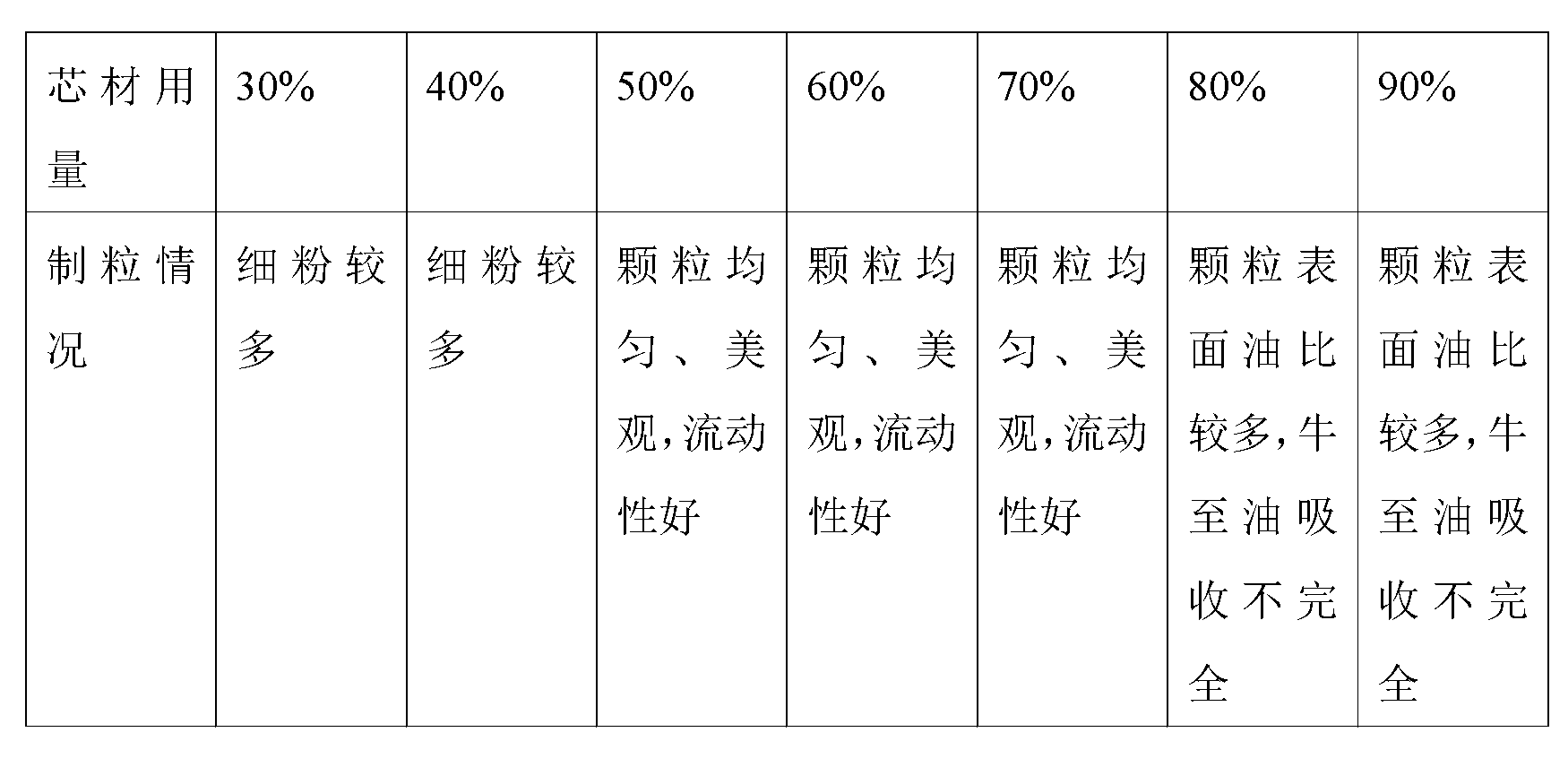

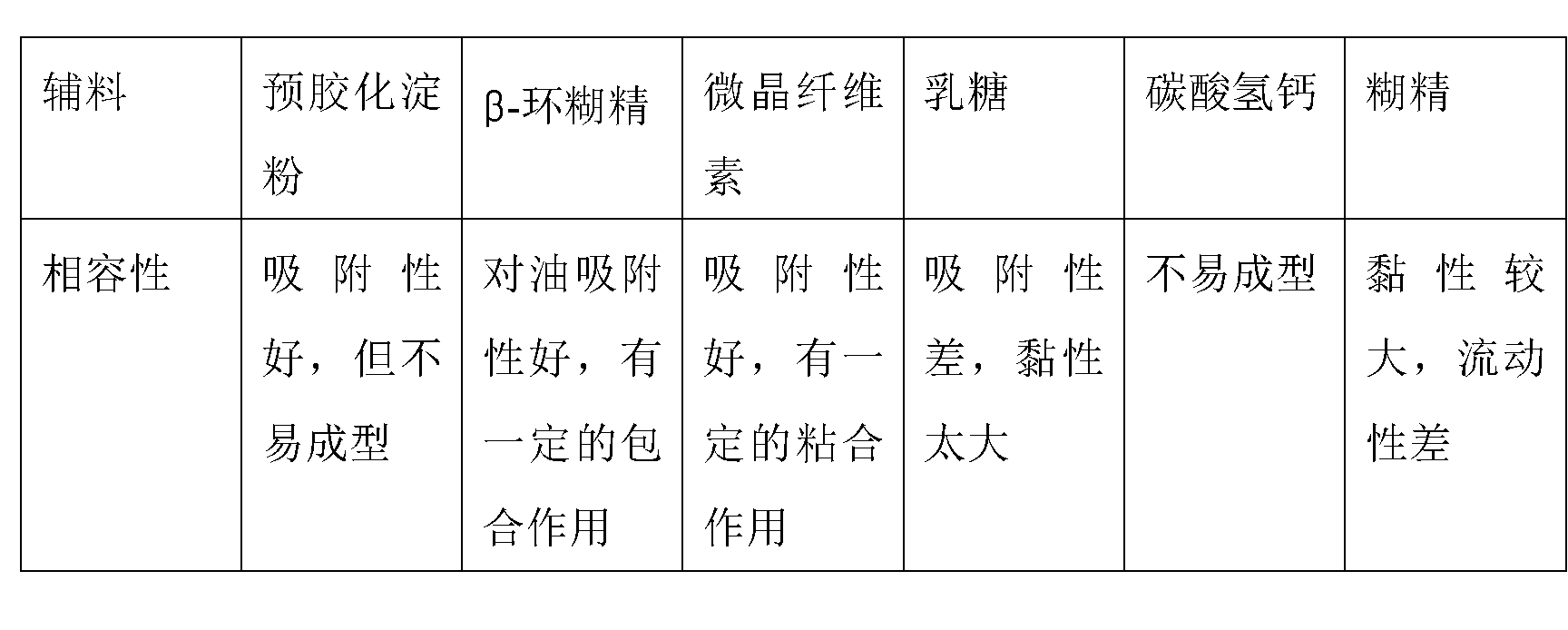

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, granules

[0045] Prepare 100kg of oregano genol-coated granules for poultry: take 70kg of 10-15 purpose calcium carbonate as the core material, place it in a tank mixer, add 8kg of microcrystalline cellulose, 15kg of β-cyclodextrin, and fully mix; 2kg of starch beating is made into 8% starch slurry, added to the above mixture and fully stirred, taken out and then placed in a blast drying oven for drying, then placed in a coating pan after drying, sprayed into 5kg of natural oregano genol while stirring, Mix well to get 5% poultry natural oregano genol-coated granules.

Embodiment 2

[0046] Embodiment 2, granules

[0047] Prepare 100kg of oregano genol-coated granules for poultry: take 60kg of 15-20 mesh silicon dioxide as the core material, place it in a tank mixer, add 5kg of microcrystalline cellulose, 20kg of β-cyclodextrin, and mix thoroughly; Beat 5kg of starch to make 8% starch slurry, add it to the above mixture and stir well, take it out and put it in a blast drying oven to dry, put it in a coating pan after drying, and spray 10kg of natural oregano phenol into it while stirring , fully mixed to get 10% poultry natural oregano phenol-coated granules.

Embodiment 3

[0048] Embodiment 3, granules

[0049] Prepare 100kg of oregano genol-coated granules for poultry: take 50kg of 20-40 mesh silicon dioxide as the core material, place it in a tank mixer, add 10kg of microcrystalline cellulose, 20kg of β-cyclodextrin, and mix thoroughly; Beat 5kg of starch to make 8% starch slurry, add it to the above mixture and stir well, take it out and put it in a blast drying oven for drying, put it in a coating pan after drying, and spray 15kg of natural oregano genol while stirring , Mix well to get 15% natural oregano phenol-coated granules for poultry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com