A kind of manufacturing method of sendust metal magnetic powder core

A manufacturing method and iron-silicon-aluminum technology, which is applied in the manufacture of inductors/transformers/magnets, inorganic material magnetism, electrical components, etc., can solve the problems of high product power consumption, complex process, lack of batch consistency, etc. The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

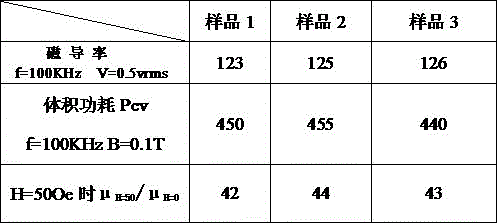

example 1

[0019] 1. Take sendust aluminum powder, in which the proportion of each component is Si9.1~10.2 by weight, and the balance of Al4.9~6.1 is Fe; the ratio of particle size is as follows: +150 mesh 5%, - 150 mesh to +300 mesh accounted for 85%, and -300 mesh accounted for 10%. In this embodiment, the Si content was 9.9, the Al content was 5.2, and the Al particle size was +100 mesh.

[0020] 2. Passivate the magnetic powder with a good ratio in step 1. The passivating agent used is an aqueous solution of 1% phosphoric acid and zinc nitrate by powder mass.

[0021] 3. After the passivation is completed, use an insulating binder to insulate and coat the powder mass of 1.5% sodium silicate and kaolin aqueous solution and dry it.

[0022] 4. After the insulating coating is completed, add 0.3% mold release lubricant and mix evenly, and dry press molding under a pressure of 1800MPa to obtain a blank.

[0023] 5. Put the blank in a protective atmosphere and keep it warm at 680°C for 1H...

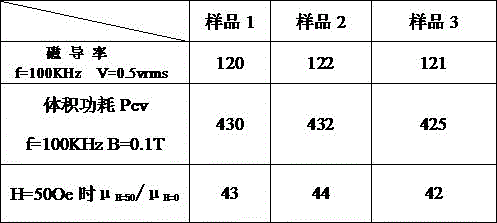

example 2

[0029] 1. Take sendust aluminum powder, in which the proportion of each component is Si9.1~10.2 by weight, and the balance of Al4.9~6.1 is Fe; the ratio of particle size is as follows: +150 mesh 5%, - 150 mesh to +300 mesh accounted for 85%, and -300 mesh accounted for 10%. In this embodiment, the Si content was 9.5, the Al content was 5.5, and the Al particle size was -50 mesh.

[0030] 2. Passivate the magnetic powder with a good ratio in step 1. The passivating agent used is an aqueous solution of 2% phosphoric acid and zinc nitrate by powder mass.

[0031] 3. After the passivation is completed, use an insulating binder to insulate and coat the powder mass of 2.5% sodium silicate and kaolin aqueous solution and dry it.

[0032] 4. After the insulating coating is completed, add 0.3% mold release lubricant and mix evenly, and dry press molding under a pressure of 2100MPa to obtain a blank.

[0033] 5. Place the blank in a protective atmosphere and heat it at 700°C for 1H for...

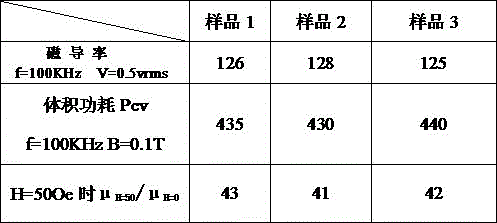

example 3

[0039] 1. Take sendust aluminum powder, in which the proportion of each component is Si9.1~10.2 by weight, and the balance of Al4.9~6.1 is Fe; the ratio of particle size is as follows: +150 mesh 5%, - 150 mesh to +300 mesh accounted for 85%, and -300 mesh accounted for 10%. In this embodiment, the Si content was 9.7, the Al content was 5.7, and the Al particle size was +150 mesh.

[0040] 2. Passivate the magnetic powder with a good ratio in step 1. The passivating agent used is an aqueous solution of 1.5% phosphoric acid and zinc nitrate by powder mass.

[0041] 3. After the passivation is completed, use an insulating binder to insulate and coat the powder mass of 2% sodium silicate and kaolin aqueous solution and dry it.

[0042] 4. After the insulation coating is completed, add 0.3% mold release lubricant and mix evenly, and dry press molding under a pressure of 2000MPa to obtain a blank.

[0043] 5. Put the blank in a protective atmosphere and keep it warm at 680°C for 1H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com