Production method of pickled radish seasoning for duck soup

A technology of sour radish and duck soup and its production method, applied in the fields of application, food preparation, food science, etc., can solve the problems affecting the flavor and quality of Laoya soup, poor quality, and insufficient cooking skills, so as to reduce damage, Guaranteed safety and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

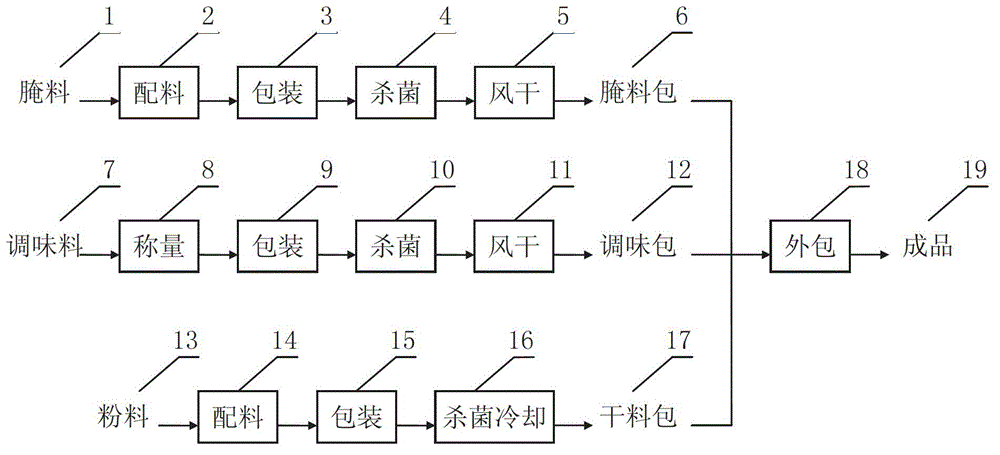

Method used

Image

Examples

Embodiment 1

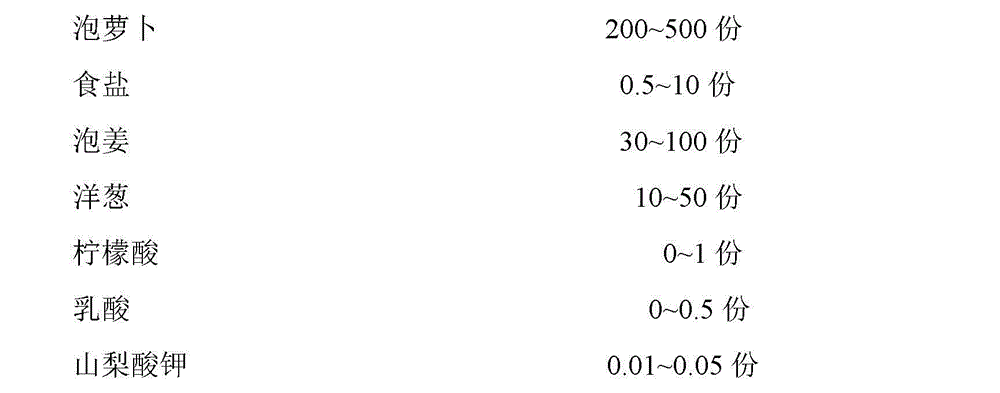

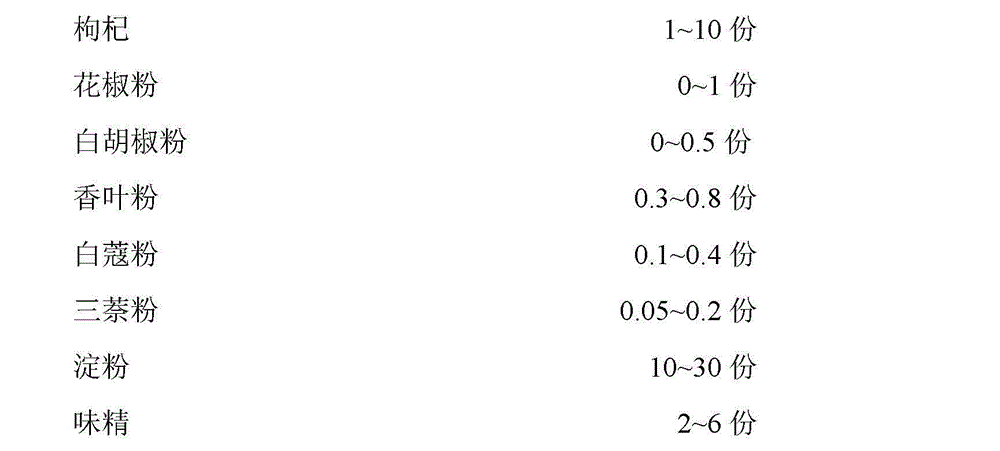

[0059]Weigh the raw materials according to the ratio of 50 parts fermented glutinous rice and 30 parts white wine, mix them evenly in a mixing tank, quantitatively fill them with a sauce filling machine and seal them at a vacuum degree of 0.08 MPa; vacuum-packed marinade packs within 1 hour Sterilization, sterilization adopts continuous water bath pasteurization; the material is placed on the chain conveyor network, and the thickness of the material accumulation does not exceed 10cm; the sterilization temperature is 85°C, the heating time is 10min, the constant temperature time is 25min, and the cooling time is 15min; the surface of the packaging bag is wiped manually Dry to get the marinade package; weigh the raw materials according to the ratio of 200 parts of soaked radish, 10 parts of table salt, 100 parts of pickled ginger, 50 parts of onion, 1 part of citric acid, and 0.01 part of potassium sorbate, and mix them evenly; Packing method Put the seasoning into the cooking ba...

Embodiment 2

[0061] Weigh the raw materials according to the ratio of 50 parts fermented glutinous rice and 40 parts cooking wine, mix them evenly in a mixing tank, quantitatively fill them with a sauce filling machine and seal them at a vacuum degree of 0.09 MPa; vacuum-packed marinade packs within 1 hour Sterilization, sterilization adopts continuous water bath pasteurization; put the material on the chain conveyor network, and the thickness of the material accumulation does not exceed 10cm; the sterilization temperature is 90°C, the heating time is 12min, the constant temperature time is 15min, and the cooling time is 25min; the marinade is wrapped in an air dryer Blow dry vigorously to get the marinade package; weigh the raw materials according to the ratio of 500 parts of soaked radish, 0.5 part of table salt, 30 parts of pickled ginger, 10 parts of onion, 0.5 part of lactic acid, and 0.05 part of potassium sorbate, and mix them evenly; Filling method Put the seasoning into the cooking...

Embodiment 3

[0063] Weigh the raw materials according to the ratio of 30 parts of glutinous rice, 20 parts of cooking wine and 15 parts of white wine, mix them evenly in the mixing tank, quantitatively fill them with a sauce filling machine and seal them at a vacuum degree of 0.09MPa; the marinade package after vacuum packaging Sterilize within 1 hour, the sterilization adopts continuous water bath pasteurization; put the material on the chain conveyor network, and the thickness of the material accumulation does not exceed 10cm; the sterilization temperature is 87°C, the heating time is 11min, the constant temperature time is 20min, and the cooling time is 20min; pack the marinade Spread it flat in a clean, cool and ventilated place to air-dry to get the marinade package; weigh 300 parts of soaked radish, 6 parts of salt, 50 parts of pickled ginger, 20 parts of onion, 0.8 part of citric acid, 0.3 part of lactic acid, and 0.04 part of potassium sorbate. Take the raw materials and mix them ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com